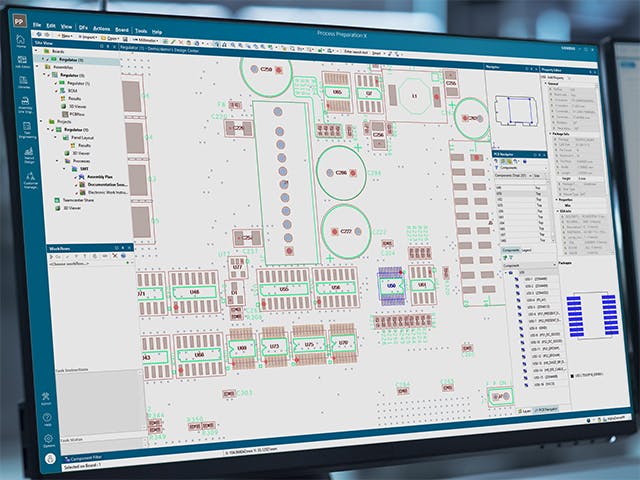

Process Preparation X - Advanced is the ultimate solution to enable first-time-right programming for your electronic assembly operations. Additionally, you can incorporate component parametric data to further refine your workflows and ensure precise manufacturing planning.

Key features of Process Preparation X Advanced

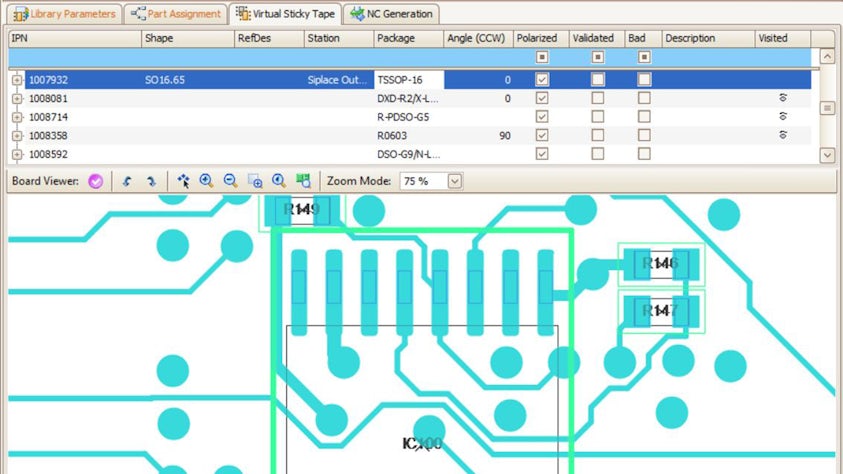

SMT/Inspection Programming Support: Provides advanced programming for surface-mount technology and optical inspection equipment, simulating and validating placements offline before physical production to ensure accuracy.

Test & Inspection Output Support: Automates the creation of inspection templates and supports in-circuit (ICT) and flying probe tests (FPT), streamlining inspection programming and reducing debugging times.

Digital Twin Integration: Builds a complete digital twin of the product and its manufacturing processes, ensuring real-time, synchronized data across the entire production cycle.

Offline Simulation: Enables offline simulation to verify program effectiveness before production, minimizing trial-and-error delays and improving line efficiency.

Cross-Vendor Machine Compatibility: Ensures that process preparation data can be seamlessly transferred between different machine vendors, accommodating diverse manufacturing equipment.

Sustainability Features: Supports sustainability by reducing material waste, lowering energy consumption through optimized production scheduling, and enhancing supply chain efficiency.

About Process Preparation X

Process Preparation X is a comprehensive process planning solution designed to accelerate high-mix, low-volume electronics production. By leveraging advanced electronic assembly collaboration, it enables seamless global engineering while reducing complexity and the total cost of ownership. With Process Preparation X, manufacturers gain a secure, constantly improving, future-proof technology suite that streamlines workflows, minimizes existing manual errors, and adapts effortlessly to any shop floor operation.

Benefits of Process Preparation X:

- Increases engineering efficiency by using a single tool for all process engineering tasks

- AI-powered preparation work with auto-generation (AG) of machine component libraries.

- Maximizes offline preparation to eliminate online trial-and-error delays

- Increases work instruction authoring efficiency through automation and use of templates.

- Preserves manufacturing know-how including best practices, libraries, and customer data preparation flows.