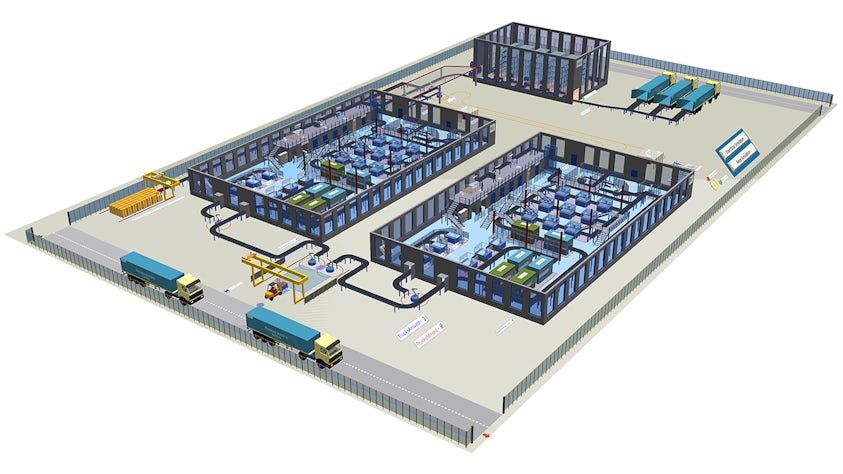

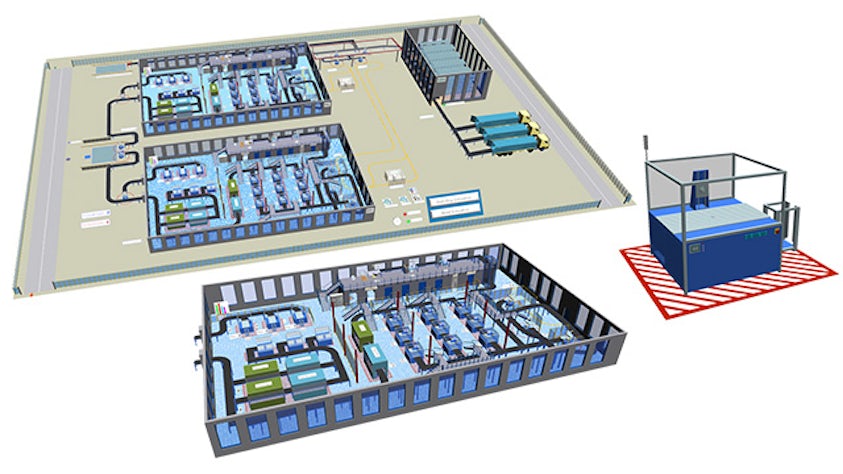

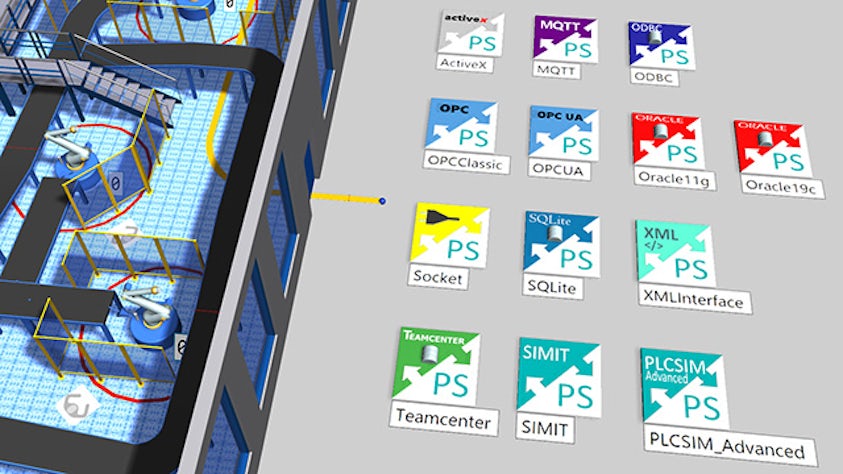

Get to market faster by allowing your manufacturing and production engineering organizations to digitally validate manufacturing and logistics systems upfront and throughout the lifecycle of new product introductions.

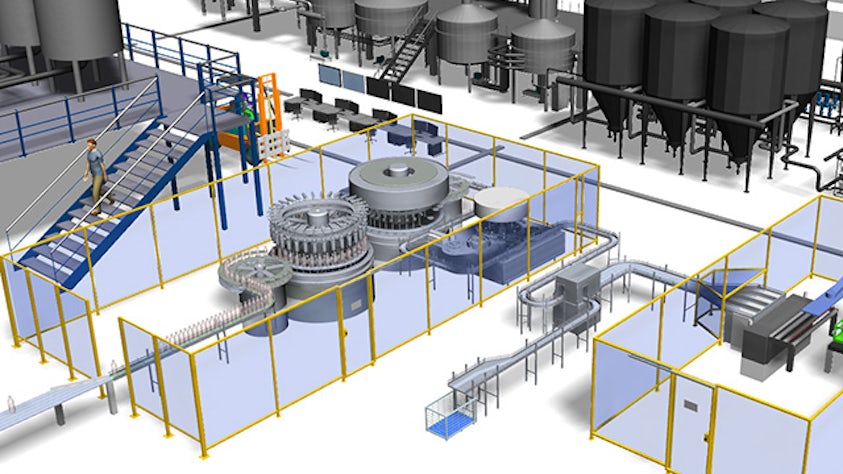

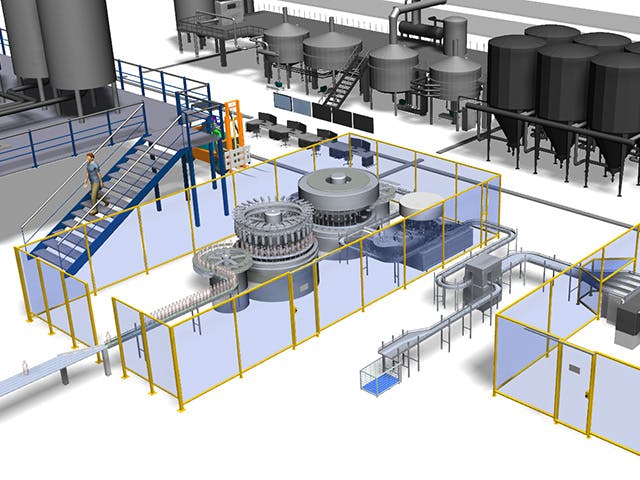

Leverage 3D models of products, resources and factories to facilitate simulation, validation and optimization of complex production and logistics processes involving material flow, equipment and people for faster launches and higher production quality.