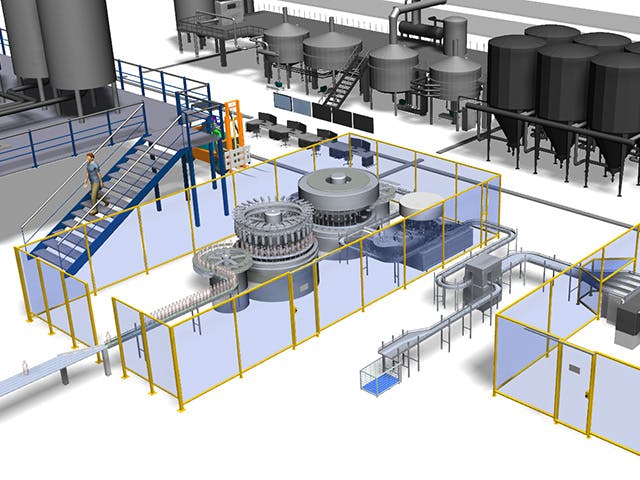

Simulate, visualize, analyze and optimize production systems and logistics processes based on models created using Plant Simulation X software authoring tools.

Key features

Execute simulations to validate and optimize production and logistics

Optimize material flow, resource utilization and logistics for all levels of plant planning, from global facilities and local plants to specific production lines.

Input production data to further increase confidence in your models

Feed actual shop floor data to your production model and easily run experiments by adjusting simulation model parameters to validate and optimize production throughput and overall system performance.

Leverage an open system architecture

Support multiple interfaces and integration capacities—including ActiveX, CAD, Oracle SQL, ODBC, XML, Socket, OPC, etc.—to further enhance your simulation models and experiments.

About Plant Simulation X

Plant Simulation X is a software-as-a-service (SaaS) solution with industry-leading digital manufacturing capabilities used to simulate, explore, analyze and optimize production and logistics at all levels of planning. Access hierarchical models of production facilities, lines and operations in a 3D environment with the added benefits of flexibility, collaboration, security and scalability of a cloud-based software.

The streamlined software deployment and configuration enables higher productivity and immediate expansion of your manufacturing capabilities. The cost-effective and customizable Plant Simulation X products are tailored for different levels of digital manufacturing complexity.

Benefits of Plant Simulation X Runtime

- Generate graphical outputs for analysis of throughput, resource utilization, automatic bottleneck detection, Sankey diagrams and Gantt charts

- Calculate and optimize energy usage for factories, lines and machines

- Visualize and animate online in 3D based on the ISO-standard JT format

- Experiment using integrated neural networks and automated system optimization via genetic algorithms

Benefits of Plant Simulation X

- Optimize the performance and energy usage of existing production systems before implementation

- Maximize efficiency and utilization of resources and identify bottlenecks during the planning phase

- Improve productivity and minimize the investment cost of production lines

- Enhance collaboration among stakeholders using cloud-based solutions