Boost your capabilities by extending your Process Simulate X software using the Augmented Reality (DTA) add-on, which allows you to customize Process Simulate X to fit your project's unique needs.

Process Simulate X Augmented Reality Digital Twin Alignment (DTA) is a powerful add-on application that uses augmented reality, inexpensive cameras and real-time computational calibration for sub-millimeter accuracy to analyze the alignment of Process Simulate studies to their real world twins.

Key features and benefits

Cell and asset alignment

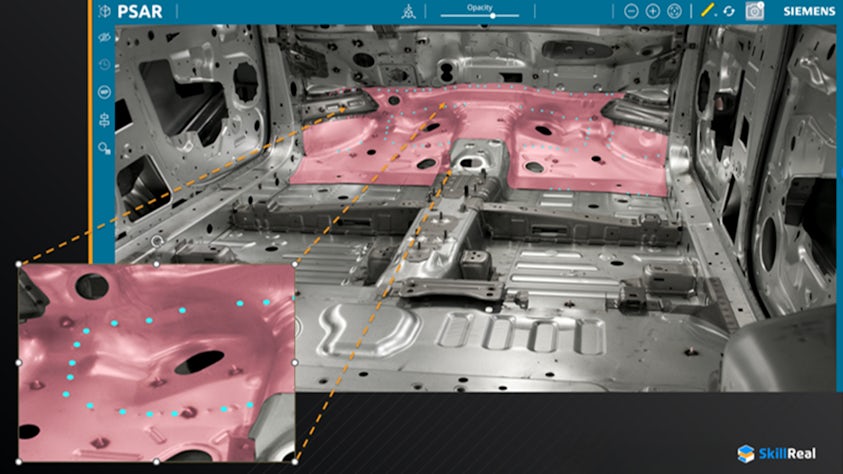

Overlay 3D models quickly to identify and measure deviations between the digital model and the real world. Integrate these findings easily into Process Simulate studies to adjust the digital model based on real-world production data.

Weld point and bolt inspection

Integrate directly with Process Simulate studies to provide an augmented view of digital and real CAD models, including weld points, allowing for precise classification and measurement.

Report generation and feedback

Generate reports in CSV format, maintaining an identical coordinate system, and feed production information back into engineering for accurate measurements and improved processes.

About Process Simulate X

Process Simulate X is a software-as-a-service (SaaS) solution with extensive digital manufacturing capabilities for planning, simulating and validating human tasks, robotics processes and automation in a 3D environment with the added benefits of flexibility, security and scalability of a cloud-based software.

The streamlined software deployment and configuration enables higher productivity and immediate expansion of your manufacturing capabilities. The cost-effective and customizable Process Simulate X software products are tailored for different levels of digital manufacturing complexity.

Process Simulate X software add-ons

Powerful add-ons allow you to easily extend the software capabilities as your modeling and simulation requirements increase over time.

Benefits of Process Simulate X software

- Plan, simulate and validate using advanced digital manufacturing tools tailored to your specific needs

- Reduce costs with early detection and communication of product design and manufacturing process issues using cloud technology

- Increase process quality by emulating realistic processes

- Improve collaboration among stakeholders using cloud-based solutions

Expand the functionality of your Process Simulate X software products with these other add-ons

- Automatic Path Planner

- Cables

- Safety Robots Manager

- Point Cloud

- Virtual Reality

- Connector for NVIDIA Omniverse