Boost your capabilities by extending your Process Simulate X software using the Cables add-on, which allows you to customize Process Simulate X to fit your project's unique needs.

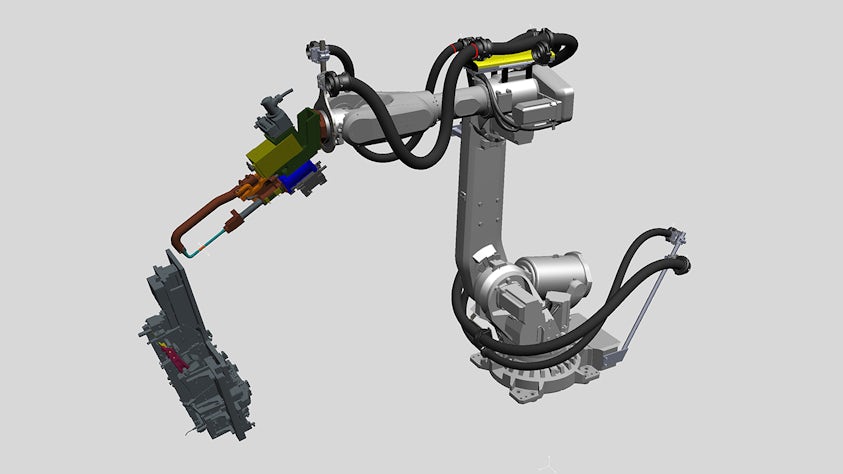

Process Simulate X Cables is a powerful add-on application that helps you define robot cables and conduct realistic cable simulations to validate them during robot motion planning and offline programming.

Key features and benefits

Create cables and cable attachments

Use the Cables add-on to create and configure cables that resemble and act like the cables on your shopfloor robot. You can attach the cable to the robot body at selected points to better represent the real robot-cable relationship, including fixed and rotating attachment types and various retraction systems.

Simulate cables

Use cable simulation for a realistic representation of how they will move and react during robot motion and to visualize potential interferences and other cable issues.

Analyze cables

Use dedicated tools to analyze cables for length, placement, connection points, curvature, twist, contact force and collisions during path planning, simulation and robot program execution.

About Process Simulate X

Process Simulate X is a software-as-a-service (SaaS) solution with extensive digital manufacturing capabilities for planning, simulating and validating human tasks, robotics processes and automation in a 3D environment with the added benefits of flexibility, security and scalability of a cloud-based software.

The streamlined software deployment and configuration enables higher productivity and immediate expansion of your manufacturing capabilities. The cost-effective and customizable Process Simulate X software products are tailored for different levels of digital manufacturing complexity.

Process Simulate X software add-ons

Powerful add-ons allow you to easily extend the software capabilities as your modeling and simulation requirements increase over time.

It is recommended that you have either a Process Simulate X Robotics Standard or Process Simulate X Robotics Advanced license to use the Cables add-on.

Benefits of Process Simulate X software

- Plan, simulate and validate using advanced digital manufacturing tools tailored to your specific needs

- Reduce costs with early detection and communication of product design and manufacturing process issues using cloud technology

- Increase process quality by emulating realistic processes

- Improve collaboration among stakeholders using cloud-based solutions

Expand the functionality of your Process Simulate X software products with these other add-ons

- Augmented Reality (Digital Twin Alignment)

- Automatic Path Planner

- Safety Robots Manager

- Point Cloud

- Virtual Reality

- Connector for NVIDIA Omniverse