Process Simulate X Essentials is a powerful, entry-level digital manufacturing solution that features core manufacturing planning, simulation and validation capabilities, including modeling, simulation for assembly, and dynamic collision checking for both discrete and continuous manufacturing processes.

The integrated digital manufacturing tools, including a set of CAD interfaces, allow you to import 3D models of products and resources to digitally validate and optimize their manufacturing processes upfront.

Key features of Process Simulate X Essentials

Process Simulate discrete manufacturing: Design, validate and optimize manufacturing processes involving distinct operations like spot welding, drilling, riveting, fastening, and pick & place.

Process Simulate continuous manufacturing: Define, validate and optimize manufacturing processes based on the creation of continuous motion paths for seam welding, gluing, sealing, polishing, painting and spraying applications.

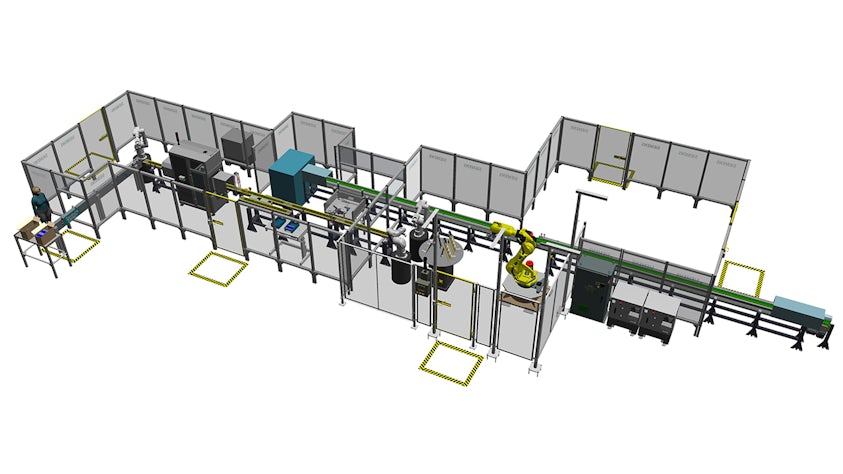

Factory design: Create and edit geometric models to represent components and assemblies, helping achieve the accurate digital twin of the manufacturing environment. Define and modify kinematics data to simulate the motion and interaction of parts for a realistic analysis of automation equipment and workflows to optimize factory layout and operations. Import CAD data directly to build a realistic digital twin of production.

Simulation for assembly: Design, analyze and verify assembly and disassembly processes by creating and simulating assembly paths and operation sequences, conducting collision detection and performing 2D/3D sectioning in a highly dynamic 3D environment.

About Process Simulate X

Process Simulate X is a software-as-a-service (SaaS) solution with industry-leading digital manufacturing capabilities for planning, simulating and validating human tasks, robotics processes and automation in a 3D environment with the added benefits of flexibility, security and scalability of a cloud-based software.

The streamlined software deployment and configuration enables higher productivity and immediate expansion of your manufacturing capabilities. The cost-effective and customizable Process Simulate X products are tailored for different levels of digital manufacturing complexity.

Benefits of Process Simulate X:

- Plan, simulate and validate using advanced digital manufacturing tools tailored to your specific needs

- Reduce costs with early detection and communication of product design and manufacturing process issues using cloud technology

- Increase process quality by emulating realistic processes

- Improve collaboration among stakeholders using cloud-based solutions

- Expand the functionality of your solutions with add-ons

Expand the functionality of the Process Simulate X products with add-ons:

- Point Cloud

- Connector for NVIDIA Omniverse

- Virtual Reality

- Automatic Path Planner

- Cables

- Safety Robots Manager

- Augmented Reality (Digital Twin Alignment)