Plant Simulation X Advanced s'appuie sur le produit Standard et intègre plusieurs fonctionnalités de simulation statistique avancées afin de modéliser, simuler, explorer et optimiser les systèmes de production et leurs processus pour les flux de matières, le débit, l'utilisation des ressources, la consommation d'énergie et la logistique à tous les niveaux de la planification de la fabrication et de la conception d'usine avec une taille de modèle illimitée.

Validez et optimisez le flux des matières, le débit et les performances globales du système avec un niveau de confiance élevé avant la production. Les outils de fabrication numérique intégrés vous permettent d'importer des modèles CAO 3D, d'optimiser la gestion des ressources et d'améliorer les processus de prise de décision dans la planification de la fabrication et de la logistique.

Fonctionnalités clés

Simulez, validez et optimisez

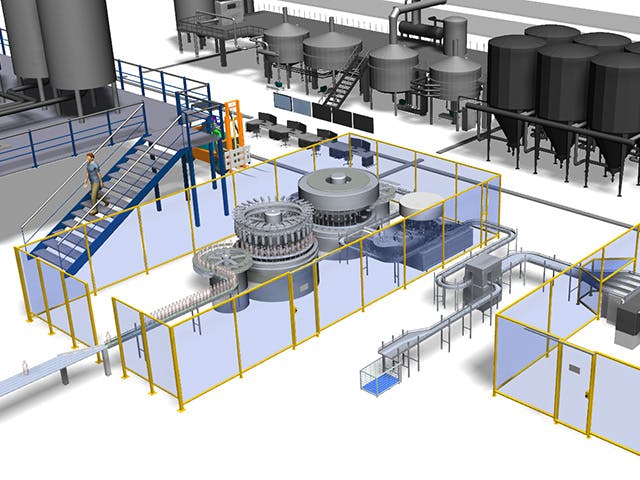

Créez des modèles de visualisation 3D du plus haut degré de complexité pour simuler, explorer et optimiser les systèmes de production et leurs processus pour les flux de matières, le débit, l'utilisation des ressources, la consommation d'énergie et la logistique à tous les niveaux de la planification de la fabrication et de la conception de l'usine. Optimisez le flux des matières, l'utilisation des ressources et la logistique à tous les niveaux de la planification de l'usine, des installations de production globales aux lignes spécifiques, en passant par les installations locales. Améliorez les modèles de simulation 3D en important directement les données CAO pour créer un jumeau numérique réaliste de la production.

Explorez et analysez

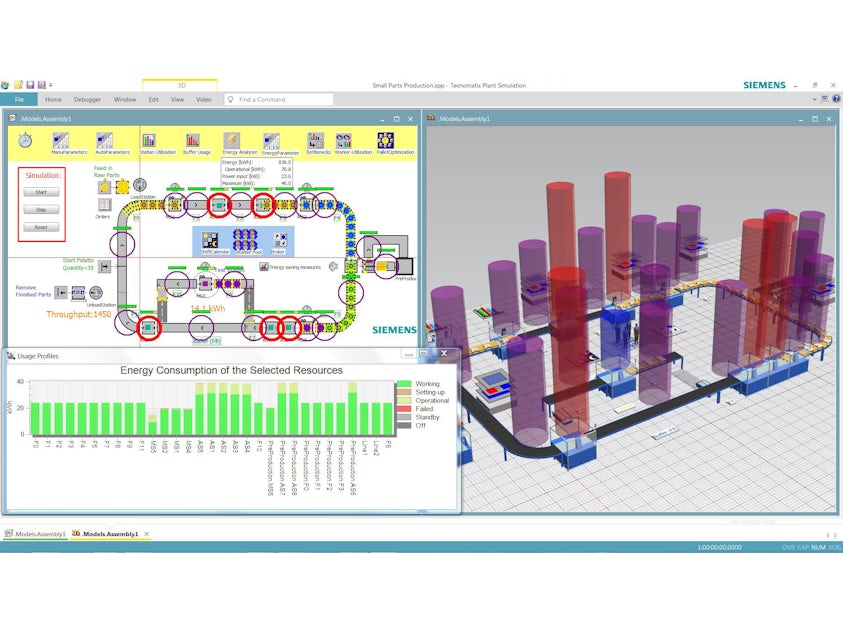

Modélisez précisément les systèmes logistiques et de production pour explorer leurs caractéristiques et optimiser leurs performances. Le modèle numérique vous permet de tester des scénarios de simulation sans perturber le système de production existant ou, lorsque le logiciel est utilisé dans le processus de planification, bien avant que le système réel soit installé. Des outils d'analyse complets, des statistiques et des graphiques vous permettent d'évaluer différents scénarios de fabrication et de prendre les bonnes décisions dès les premières étapes de planification de la production. Validez le routage des pièces et obtenez une vue complète de l'état des machines, facilitant ainsi une meilleure prise de décision et une meilleure gestion de la production.

Analyse de simulation

Rationalisez les processus d'émulation, améliorez l'analyse des données et améliorez la convivialité globale à l'aide d'outils d'analyse complets intégrés.

Analyseur de coûts

Évaluez et analysez les coûts associés à divers composants et processus au sein du modèle de simulation afin d'identifier les facteurs de coûts, d'évaluer les possibilités de réduction et d'optimiser l'allocation des ressources pour améliorer l'efficacité économique.

Analyseur d'énergie

Contrôlez et évaluez la consommation d'énergie à travers différents composants et processus pour aider à identifier les domaines d'amélioration de l'efficacité énergétique, soutenir les objectifs de durabilité et optimiser l'utilisation de l'énergie pour réduire les coûts opérationnels.

Échantillonneur séquentiel

Effectuez des études séquentielles pour déterminer les intervalles de confiance des valeurs cibles, en aidant à ajuster le nombre d'observations pour atteindre la précision souhaitée et en gérant efficacement les longues périodes d'échauffement.

Rationalisez l'échange de données

Tirez parti de l'intégration avec des technologies telles que ActiveX, C-Interface, MQTT, ODBC, OPC UA, PLCSIM Advanced, SIMIT, SQL for Oracle et Socket pour permettre un accès direct au code tiers, l'intégration de bases de données et un transfert de données efficace, améliorant ainsi la simulation et la surveillance en temps réel.

À propos de Plant Simulation X

Plant Simulation X est une solution SaaS (Software-as-a-Service) dotée de capacités de fabrication numérique de pointe, utilisée pour simuler, explorer, analyser et optimiser la production et la logistique à tous les niveaux de planification. Accédez à des modèles hiérarchiques d'installations de production, de lignes et d'opérations dans un environnement 3D avec les avantages supplémentaires en termes de flexibilité, de collaboration, de sécurité et d'évolutivité d'un logiciel basé sur le cloud.

Le déploiement et la configuration simplifiés du logiciel, permettent d'augmenter la productivité et d'étendre immédiatement vos capacités de fabrication. Économiques et personnalisables, les produits Plant Simulation X sont conçus pour différents niveaux de complexité de la fabrication numérique.

Avantages de Plant Simulation X

- Optimiser les performances et la consommation d'énergie des systèmes de production existants avant leur mise en œuvre

- Maximisez l'efficacité et l'utilisation des ressources et identifiez les goulots d'étranglement pendant la phase de planification

- Améliorez la productivité et minimisez le coût d'investissement des lignes de production

- Renforcez la collaboration entre les parties prenantes grâce à des solutions basées sur le cloud

Modules complémentaires Plant Simulation X

De puissants modules complémentaires vous permettent d'étendre facilement les capacités de votre logiciel à mesure que vos besoins en modélisation et simulation augmentent au fil du temps.