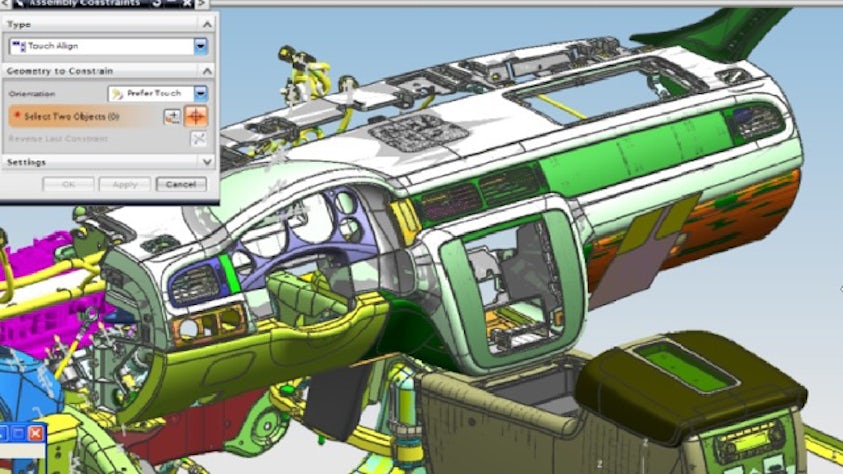

Migliora l'efficienza e la produttività con la tecnologia del modello master. NX fornisce un'unica definizione del modello della parte, utilizzabile in tutte le fasi, dalla progettazione e ottimizzazione del modello della parte alla simulazione, alla programmazione NC, alle lavorazioni CNC e al controllo della qualità. Ad esempio, se modifichi il modello in un file, la geometria viene aggiornata nello schizzo del modello 3D originale e nel modello utilizzato nella simulazione, in modo che tutti utilizzino sempre l'ultima versione del modello.