Plant Simulation X Essentials è una potente soluzione di produzione digitale entry-level che offre funzionalità di simulazione statistica di base per creare, analizzare e ottimizzare modelli 3D di sistemi di produzione e relativi processi utilizzando oggetti di base, oggetti definiti dall'utente, librerie e controlli per un massimo di 500 oggetti.

Funzionalità principali

Simula, valida e ottimizza

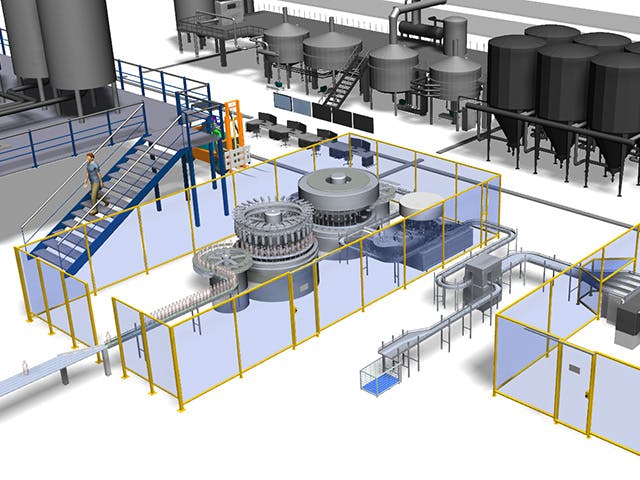

Crea modelli di visualizzazione 3D delle dimensioni di un massimo di 500 oggetti per la simulazione, la validazione e l'ottimizzazione dei sistemi e dei processi di produzione utilizzando il software Plant Simulation Essentials. Ottimizza il flusso dei materiali, l'impiego delle risorse e la logistica a tutti i livelli di pianificazione degli impianti, dagli stabilimenti di produzione globali agli impianti locali, fino alle linee specifiche.

Esplorazione e analisi

Modella accuratamente i sistemi logistici e di produzione per esplorarne le caratteristiche e ottimizzarne le prestazioni. Il modello digitale permette di realizzare esperimenti e scenari ipotetici senza interferire con i sistemi di produzione esistenti o, se utilizzati nei processi di pianificazione, molto prima dell'installazione dei sistemi reali. Grazie a strumenti di analisi completi, statistiche e grafici, gli utenti possono valutare diversi scenari di produzione e prendere decisioni rapide ed efficaci nelle fasi iniziali della pianificazione. Valida l'instradamento delle parti e ottieni una visione completa degli stati macchina, migliorando il processo decisionale e la gestione della produzione.

Scambio dati semplificato

Sfrutta l'integrazione con tecnologie come ActiveX, C-Interface, MQTT, ODBC, OPC UA, PLCSIM Advanced, SIMIT, SQL per Oracle e Socket per consentire l'accesso diretto al codice di terze parti, l'integrazione con i database e un trasferimento dei dati più efficiente, migliorando così la simulazione e il monitoraggio in tempo reale.

Informazioni su Plant Simulation X

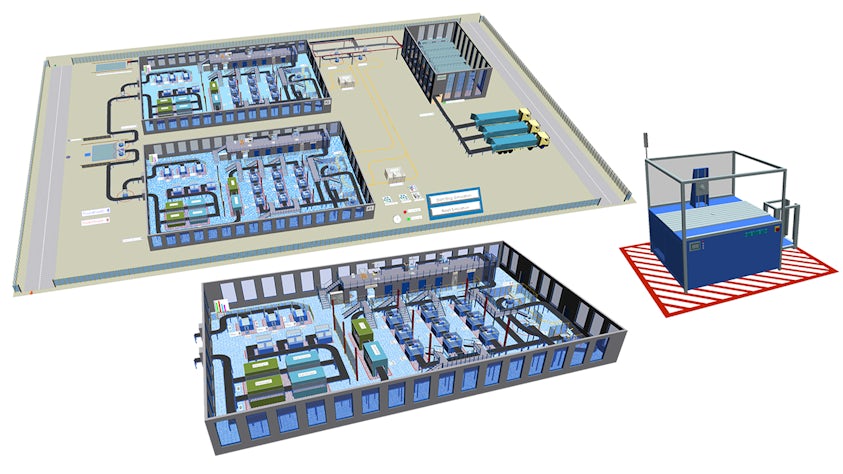

Plant Simulation X è una soluzione software-as-a-service (SaaS) con estese funzionalità di produzione digitale utilizzate per simulare, esplorare, analizzare e ottimizzare la produzione e la logistica a tutti i livelli di pianificazione. Accedi a modelli gerarchici di impianti di produzione, linee e operazioni in un ambiente 3D, con i vantaggi aggiuntivi di flessibilità, collaborazione, sicurezza e scalabilità offerti da un software basato su cloud.

L'implementazione e la configurazione ottimizzate del software consentono di aumentare la produttività e di espandere immediatamente le capacità produttive. I prodotti Plant Simulation X, convenienti e personalizzabili, sono realizzati su misura per diversi livelli di complessità della produzione digitale.

Vantaggi di Plant Simulation X:

- Ottimizzazione delle prestazioni e del consumo energetico dei sistemi di produzione esistenti prima dell'implementazione

- Massimizzazione dell'efficienza e dell'utilizzo delle risorse e rilevamento dei colli di bottiglia durante la fase di pianificazione

- Miglioramento della produttività e riduzione dei costi di investimento delle linee di produzione

- Collaborazione tra gli stakeholder ottimizzata grazie alle soluzioni basate sul cloud