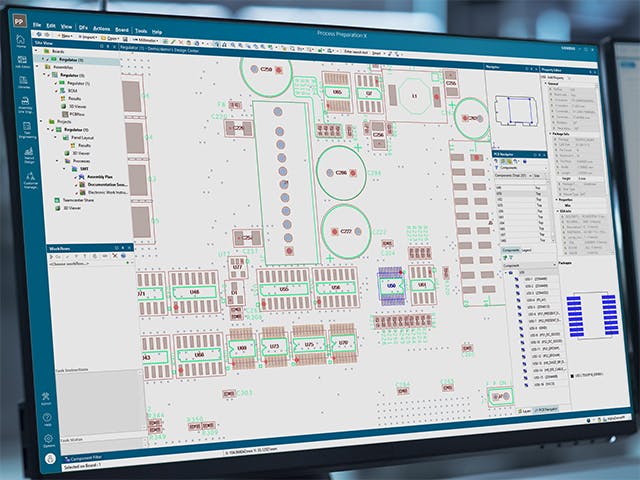

Process Preparation X Standard enhances your production capabilities by adding stencil design, electronic work instructions authoring, and essential tools to build a comprehensive digital twin of your product. By integrating component data and generating industry-standard outputs, it ensures seamless shopfloor operations and empowers efficient planning, simulation, and optimization. This all-in-one solution is designed to streamline production workflows and enhance operational efficiency before implementation, making the transition from concept to real-world application smooth and effective.

Key features of Process Preparation X Standard

Simulate, Validate, and Optimize: Create process flow models to simulate, validate, and optimize production processes. This advanced functionality helps you improve resource allocation, minimize production bottlenecks, and ensure process efficiency across every stage of planning. The addition of stencil design and work instructions functionality helps streamline operations on the shopfloor and ensures the accuracy of your production processes.

Collaborate and Analyze: Utilize a range of analysis tools, charts, and statistical features to explore and analyze various process configurations. By running "what-if" scenarios and simulations, you can evaluate process performance and make informed decisions before starting production. The integration of component data into the digital twin model supports collaboration and ensures that every step of the process is optimized.

Streamline Data Exchange: With industry-standard outputs, Process Preparation X Standard ensures accurate communication across platforms and helps maintain seamless operations on the shopfloor.

About Process Preparation X

Process Preparation X is a comprehensive process planning solution designed to accelerate high-mix, low-volume electronics production. By leveraging advanced electronic assembly collaboration, it enables seamless global engineering while reducing complexity and the total cost of ownership. With Process Preparation X, manufacturers gain a secure, constantly improving, future-proof technology suite that streamlines workflows, minimizes existing manual errors, and adapts effortlessly to any shop floor operation.

Benefits of Process Preparation X:

- Increases engineering efficiency by using a single tool for all process engineering tasks

- AI-powered preparation work with auto-generation (AG) of machine component libraries.

- Maximizes offline preparation to eliminate online trial-and-error delays

- Increases work instruction authoring efficiency through automation and use of templates.

- Preserves manufacturing know-how including best practices, libraries, and customer data preparation flows.