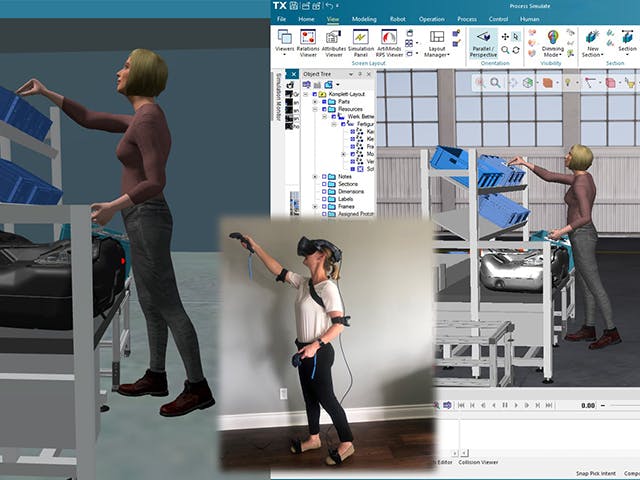

Process Simulate X Human Standardには、詳細なタスク・シミュレーションと人間工学解析が組み込まれており、さまざまなサイズのバーチャル・ヒューマンを使用して人間中心のオペレーションを設計、検証、最適化して製品の設計とアセンブリを改善するとともに、より安全で効率的な作業空間を実現します。

Process Simulate X Human Standardの主な特長

人間工学解析: 姿勢評価や、業界で規制されている基準に基づくリフティング・ガイドなど、包括的なツールを使用します。その他の機能には、カスタマイズ可能な姿勢モニタリング、目の高さのシミュレーション、全身および腕の強さの評価、代謝エネルギーと疲労蓄積の解析、静的および累積的な腰部への負担の評価、詳細な人間工学レポートの生成が含まれます。

ヒューマン・タスクの計画とシミュレーション: 3Dデジタル環境でヒューマン・モデルに指示して、異なるサイズのヒューマン・フィギュアを入れ替えたり、オブジェクトの位置を変更したり、タスクに関連する力を修正したりすることで、クイック・アニメーションやwhat-ifシナリオを進めます。

Process Simulate Collaborate: Process Simulateソフトウェアで作成した工場の生産ラインや作業セルを、革新的なクラウドベースの3Dコラボレーションを使用して、いつでも、どこでも、誰とでも可視化、レビュー、解析できます。

工場設計: コンポーネントやアセンブリを表現するジオメトリ・モデルを作成して編集し、製造環境の正確なデジタル表現を実現します。キネマティクス・データを修正して、部品のモーションと相互作用をシミュレーションし、自動化装置とワークフローの現実的な解析を行って、工場のレイアウトとオペレーションを最適化します。CADデータを直接インポートして、現実的な生産のデジタルツインを構築します。

アセンブリのためのシミュレーション: 高度に動的な3D環境で、アセンブリ・パスとオペレーション・シーケンスの作成、シミュレーション、衝突検出、2D/3Dセクショニングを実行して、アセンブリ・プロセスと分解プロセスを設計、解析、検証します。

Process Simulate Xについて

Process Simulate Xは、ヒューマン・タスク、ロボティクス・プロセス、自動化を3D環境で計画、シミュレーション、検証するための、業界をリードするデジタル製造機能を備えたSaaS (Software-as-a-Service) ソリューションです。クラウドベースのソフトウェアならではの柔軟性、セキュリティ、拡張性の利点も備えています。

ソフトウェアを効率的に導入して構成できるため、生産性が向上し、製造能力は直ちに拡張します。費用対効果が高く、カスタマイズ可能なProcess Simulate X製品は、デジタル製造のさまざまなレベルの複雑さに合わせて調整されています。

Process Simulate Xの利点:

- 特定のニーズに合わせた高度なデジタル製造ツールを使用して、計画、シミュレーション、検証

- クラウド技術を活用して製品設計や製造プロセスの問題を早期に検出し、コミュニケーションすることでコストを削減

- 現実のプロセスを模倣してプロセスの品質を向上

- クラウドベースのソリューションを使用して、関係者間のコラボレーションを強化

- アドオンにより、ソリューションの機能を拡張

アドオンでProcess Simulate X製品の機能を拡張します:

- Automatic Path Planner

- ケーブル

- 点群

- 仮想現実

- NVIDIA Omniverse向けコネクター