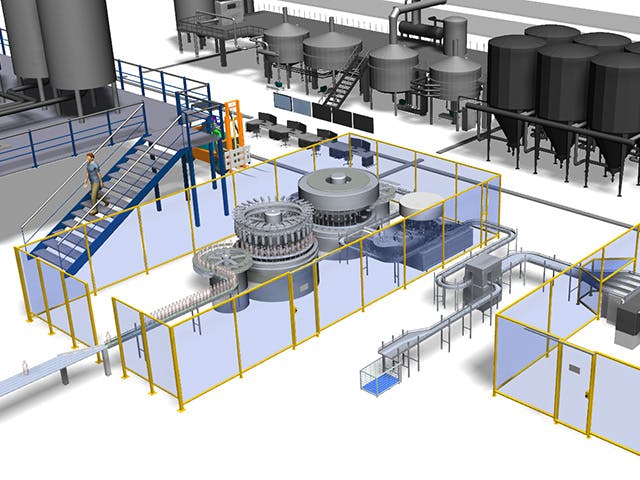

基于 Plant Simulation X 编创工具创建的模型,仿真、可视化、分析和优化生产系统和物流过程。

主要功能

执行仿真以验证和优化生产和物流

从工厂规划的各个层面(从全球生产设施到当地工厂再到特定生产线)对原料周转、资源利用和物流进行优化。

输入生产数据,进一步增强模型的信度

将实际车间数据馈送给生产模型并调整仿真模型参数以轻松运行试验,即可验证并优化产量和系统的整体性能。

充分利用开放式系统架构

支持多接口和集成功能(包括 ActiveX、CAD、Oracle SQL、ODBC、XML、SOCKET、OPC 等),以进一步增强仿真模型和试验。

关于 Plant Simulation X

Plant Simulation X 是一种软件即服务 (SaaS) 解决方案,具有行业前沿数字化制造功能,可用于仿真、探索、分析和优化各个规划级别的生产和物流。利用云端软件的灵活性、协同性、安全性和可扩展性等附加优势,在 3D 环境中访问生产设施、生产线和运营的分层模型。

简化的软件部署和配置可提高生产效率并立即扩展制造能力。经济高效且可定制的 Plant Simulation X 产品专为不同级别的数字化制造复杂性量身定制。

Plant Simulation X Runtime 的优势

- 生成图形输出。可供分析产量、资源利用以及自动瓶颈检测、桑基图和甘特图

- 计算和优化工厂、生产线和机器的能源使用情况

- 实现基于 ISO 标准 JT 格式的在线 3D 可视化和动画

- 透过集成神经网络开展试验,利用遗传算法进行自动系统优化

Plant Simulation X 的优点

- 在实施之前优化现有生产系统的性能和能源使用情况

- 尽可能提高资源的效率和利用率,并在规划阶段发现瓶颈

- 提高生产效率并尽可能降低生产线投资成本

- 使用基于云的解决方案改善利益相关者之间的协作