使用值流映射 (VSM) 库插件扩展 Plant Simulation X 解决方案以提升功能,该软件可用于自定义 Plant Simulation X 以满足项目的独特需求。

VSM 库是一组功能强大的对象,通过将值流映射的战略洞察与仿真的详细分析功能相结合,增强生产流程。该库提供的工具和功能旨在帮助用户对制造或生产环境中的值流进行建模、仿真、分析和优化。

我们将不断推出新的插件,以拓宽建模和仿真能力。

主要功能

预建 VSM 元素

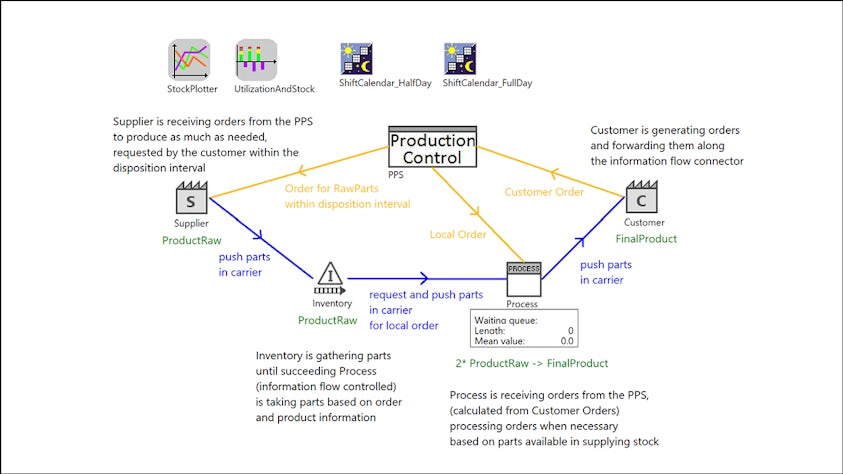

利用值流映射中常用的预配置元素和模板,如流程、缓冲区、运输链接和信息流,复制现实世界的生产活动,并随时可以集成到仿真中。

值流的可视化表示

创建生产流程的详细可视化表示,镜像传统的值流映射,但增加了动态仿真的功能,可以对整个值流进行更具交互性和数据丰富的分析。

动态仿真

运行值流的动态仿真,观察流程某一部分的变化如何影响整个系统,从而深入了解不同场景下的可变性、瓶颈和系统行为。

数据驱动型分析

收集并分析关键绩效指标,如周期时间、交付时间、在制品 (WIP) 和资源利用率,以便准确识别效率低下的情况和潜在改进的影响。

场景比较

在仿真中创建和比较多个场景,例如当前状态与未来状态,或不同的流程改进策略,以帮助在实施各种精益计划之前评估其有效性。

交互式迭代改进

通过迭代修改和优化值流模型来支持持续改进,每次迭代都会提供反馈,可用于进一步完善流程。

关于 Plant Simulation X

Plant Simulation X 是一种软件即服务 (SaaS) 解决方案,具有行业前沿数字化制造功能,可用于仿真、探索、分析和优化各个规划级别的生产和物流。利用云端软件的灵活性、协同性、安全性和可扩展性等附加优势,在 3D 环境中访问生产设施、生产线和运营的分层模型。

简化的软件部署和配置可提高生产效率并立即扩展制造能力。经济高效且可定制的 Plant Simulation X 产品专为不同级别的数字化制造复杂性量身定制。

Plant Simulation X 插件

强大的插件允许您在随着时间的推移而增加建模和仿真需求时,轻松扩展软件功能。

VSM 库插件需要 Plant Simulation X 标准版或 Plant Simulation X 高级版许可证。

Plant Simulation X 的优点

- 在实施之前优化现有生产系统的性能和能源使用情况

- 尽可能提高资源的效率和利用率,并在规划阶段发现瓶颈

- 提高生产效率并尽可能降低生产线投资成本

- 使用基于云的解决方案改善利益相关者之间的协作

- 使用插件扩展软件的功能