Legen Sie die Leistungsfähigkeit des digitalen Zwillings in die Hände von Betriebsleitern und Fertigungsleitern, damit sie die Produktionsleistung im täglichen Betrieb zuverlässig vorhersagen und optimieren können. Erreicht wird dies durch eine vereinfachte Erstellung des digitalen Zwillings der Fabrik und seine leichte Anwendbarkeit in der Fertigung.

Wesentliche Funktionen

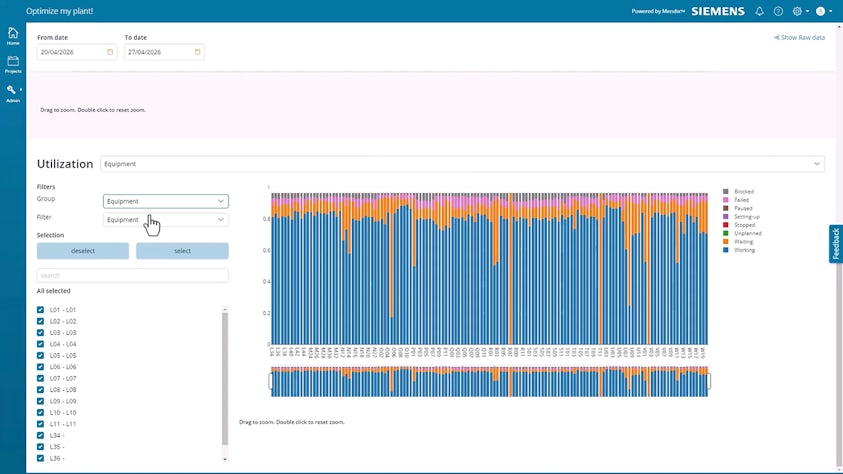

- Engine zur prädiktiven Simulation

- Modellerweiterungen von Plant Simulation mit Mendix Low-Code

- Materialflussanalyse, Durchsatzbewertung, Energieverbrauchsberechnung und vieles mehr

- Dashboards, detaillierte Diagramme und Ergebnisausgaben

Info über Plant Simulation X

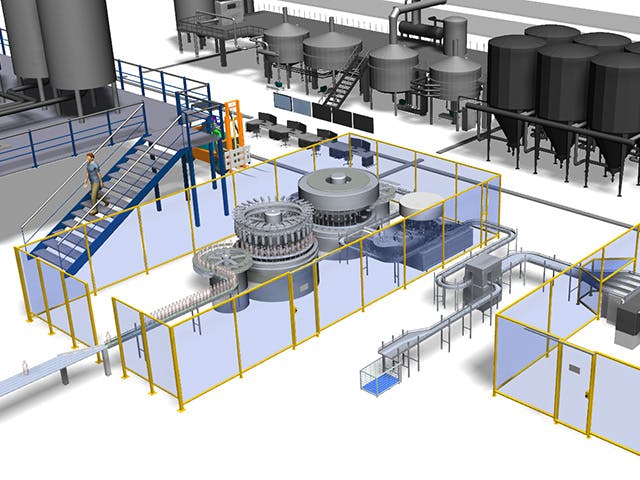

Plant Simulation X ist eine Software-as-a-Service (SaaS)-Lösung mit umfangreichen digitalen Fertigungsmöglichkeiten, mit der Produktion und Logistik auf allen Planungsebenen simuliert, erforscht, analysiert und optimiert werden kann. Greifen Sie auf hierarchische Modelle von Produktionsanlagen, -linien und -abläufen in einer 3D-Umgebung zu, mit den zusätzlichen Vorteilen der Flexibilität, Zusammenarbeit, Sicherheit und Skalierbarkeit einer cloudbasierten Software.

Die optimierte Softwarebereitstellung und -konfiguration sowie die wertbasierte Lizenzierung ermöglichen eine höhere Produktivität und eine sofortige Erweiterung Ihrer Fertigungskapazitäten. Die kostengünstigen und anpassbaren Produkte von Plant Simulation X sind auf unterschiedliche Komplexitätsstufen der digitalen Fertigung zugeschnitten.

Über Mendix

Mendix ist eine branchenführende All-in-One-Plattform für die Entwicklung von Low-Code-Anwendungen. Seit 2005 haben Tausende von Unternehmen auf der ganzen Welt die Art und Weise, wie sie Anwendungen entwickeln, neu konzipiert und dabei die bahnbrechenden Funktionen der Mendix-Plattform genutzt.

Durch die Überbrückung von Kommunikations- und Kooperationslücken zwischen Business und IT hilft Mendix Unternehmen, Ideen schneller in Ergebnisse umzusetzen, indem komplexe Anwendungen rascher bereitgestellt werden.

Vorteile von Optimize my plant:

- Verbesserung der Liefertreue und Anlagenauslastung

- Vorhersage von Auftragslieferterminen und Optimierung von Zeitplänen

- Begrenzung von Vibrationen im Produktionsprozess

- Vereinfachung der Datenerfassung und -kontextualisierung

- Softwarebasierter digitaler Zwilling der Produktion mit Plant Simulation