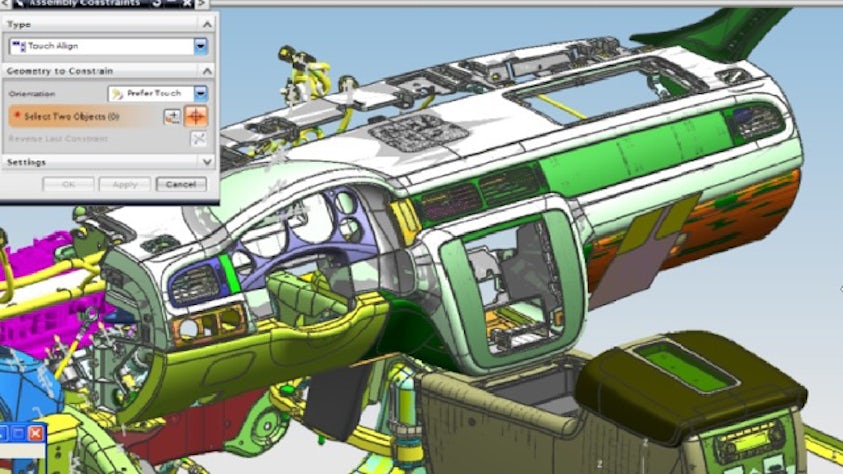

Improve your efficiency and productivity with master model technology. NX provides a single model definition of the part—usable from part model design and optimization to simulation, NC programming and CNC machining, and quality inspection. For example, if you modify the model in one file, the geometry gets updated in the original 3D model sketch and the model used in simulation, which makes sure you are always working on the current version of the model.