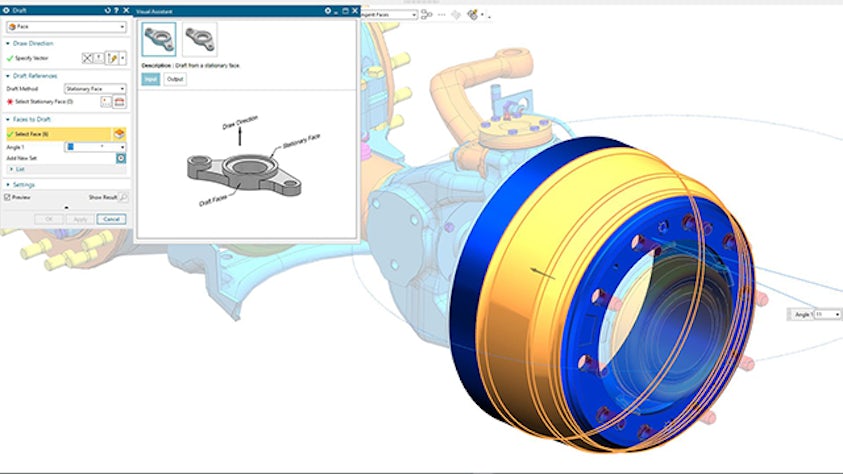

Leverage the NX personal assistant that uses artificial intelligence (AI) and machine learning to track and learn from user actions. This feature predicts the NX commands you will likely use next based on the context of what you are currently doing. It then presents those commands on a compact adaptive user interface (UI) panel. For example, if you're doing something in sheet metal, it knows that a certain sequence of commands will be used and will provide them to you.