Integrate part manufacturing using NX CAD/CAM

NX provides powerful CAD/CAM capabilities that enable seamless manufacturing—from digital part models to NC programming to finished precision components—using one software system.

Learn about our advanced CAD tools for NC programming:

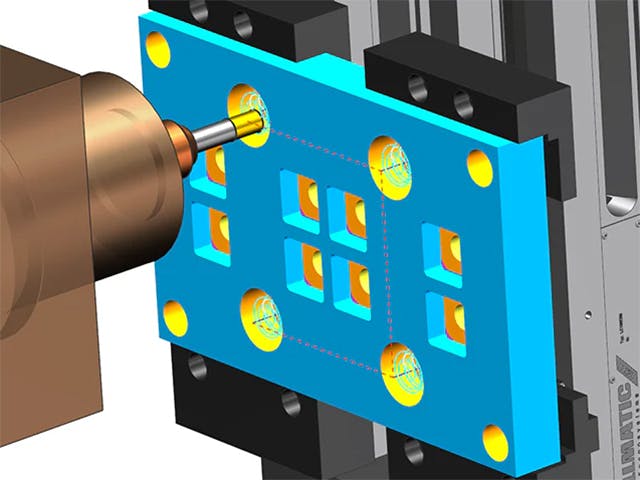

Accelerate part model preparation

Use synchronous technology to directly edit 3D part models to prepare them for NC programming, including:

- Closing holes and gaps

- Copying or moving features

- Offsetting faces

- Resizing part features

These advanced design tools help you create efficient toolpaths to machine high-quality parts.

The full associativity to the original CAD data helps you easily implement design and process change requests.

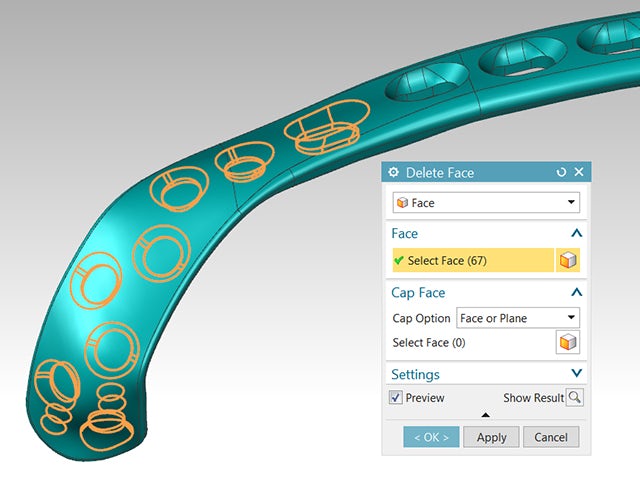

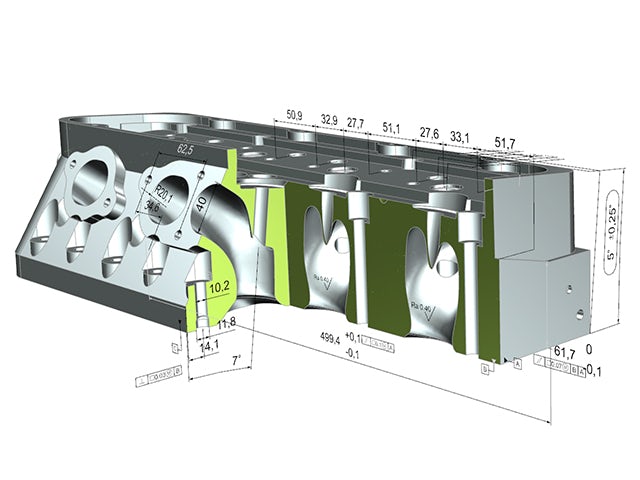

Drive manufacturing processes using PMI

Capture part manufacturing requirements using product and manufacturing information (PMI), such as geometric dimensioning and tolerancing (GD&T), surface finish and material specifications.

Save up to 90% of programming time using PMI, which enables automated NC programming. From driving the selection of operations, tools and machining tolerances, PMI helps you achieve manufacturing requirements.

Leverage fully-integrated CAD tools

Rapidly prepare and program parts using the latest CAD technology in NX, including:

- Read, repair and modify CAD data

- Design workpieces, blanks and fixtures using solid and surface modeling

- Build a library of standard components for reuse

- Create associative engineering drawings using drafting capabilities

- Define job setups using assembly and kinematics functions

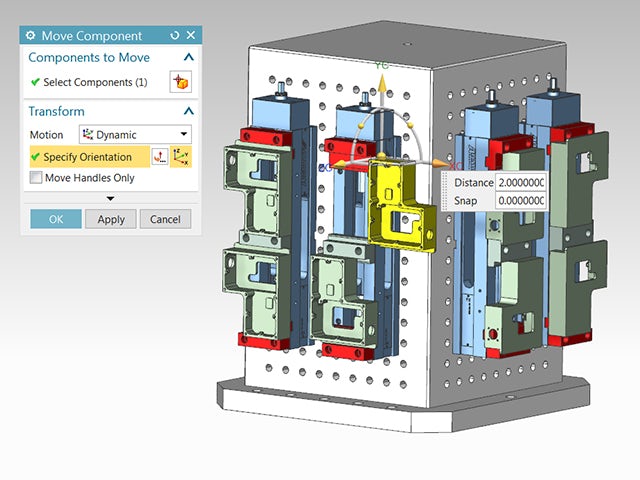

Connect manufacturing with model-driven processes

Facilitate concurrent manufacturing by linking all functions to the single-part model definition—from CAD and CAM to CNC machining and quality inspection.

Associativity enables you to handle engineering change orders (ECO) easily, ensuring you use the correct data in production.

Digitally connect end-to-end part manufacturing processes using an integrated CAD/CAD system, boosting your productivity.

Cosmos Industrial

Siemens Digital Industries Software solution drives innovation for leading automotive component manufacturer

Company:Cosmos Industrial

Industry:Automotive & transportation

Location:Vinh Yen and Vinh Phuc, Vietnam

Siemens Software:NX

Explore NX X Manufacturing products

Get more details about our wide range of cloud solutions for your specific part manufacturing needs.

Siemens Teamcenter Share

Optimize your entire production process with Teamcenter Share, a cloud-based collaboration solution, which seamlessly connects to NX CAM software. Securely communicate and share information with internal and external stakeholders in the cloud.

Connect design, manufacturing and shop floor teams to run more flexible and efficient production.