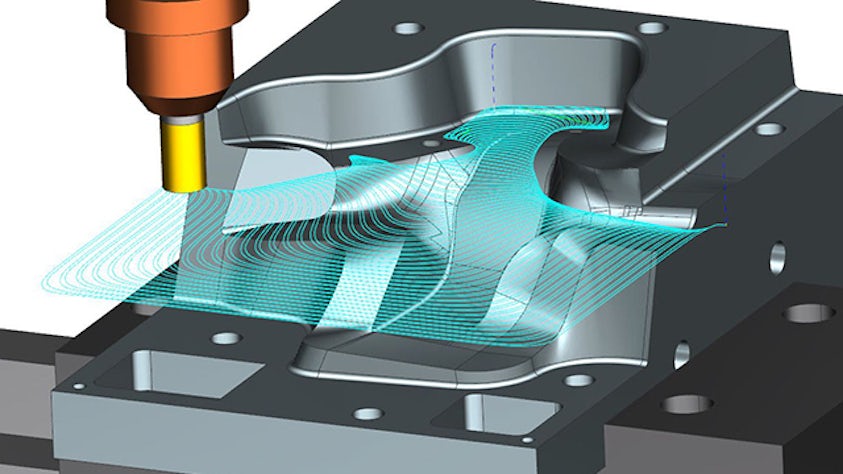

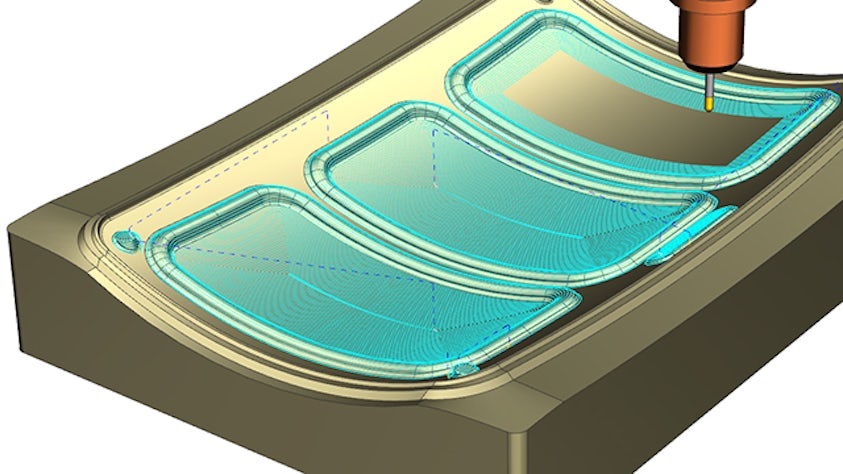

NX X Manufacturing Advanced builds upon the Standard product, incorporating advanced 3- and 2.5-axis milling, turning and on-machine probing capabilities, among other functionalities. The industry-leading integrated CAD/CAM tools streamline the preparation and programming of the most demanding freeform parts, such as molds and dies. The powerful toolpath technologies enable the machining of parts with superior surface finish while reducing cutting time by up to 60%.

Key features

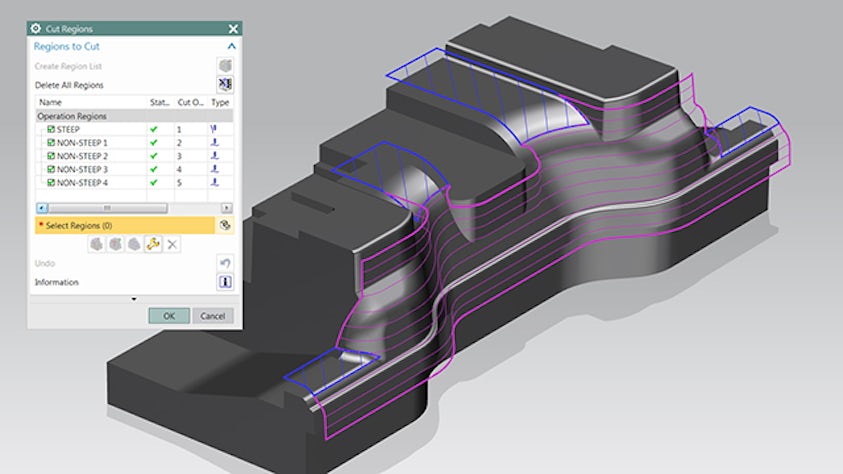

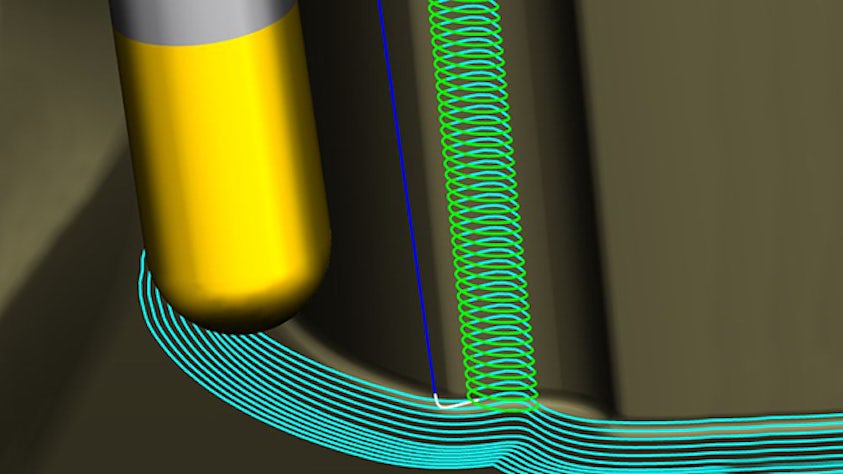

3-axis milling: Manufacture high-quality components with freeform features using a complete set of advanced numerical control (NC) programming tools. The 3D Adaptive Roughing can reduce machining time by half. Automated rest milling enables multi-stage roughing, boosting throughput. Cut region control methods provide precise control of machining strategies. Achieve a high-quality surface finish with smooth finishing strategies that can follow the natural shape of the part geometry.

Data management: gain access to CAM data management and enable cloud file management, including check-in and check-out of manufacturing files and revision control. Explore features that help identify dependencies between design parts and CAM setups, while integrated discussion threads and task assignments support cross-functional collaboration between designers and manufacturers.

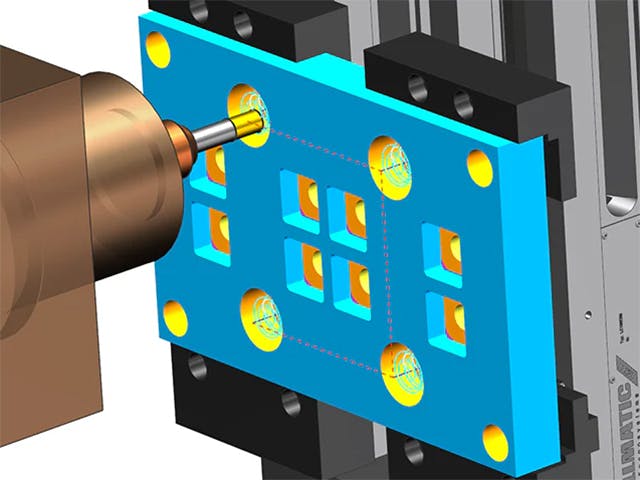

2.5-axis milling: Machine with volume-based milling to enable faster programming of prismatic parts, and feature-based machining automates programming. High-speed machining strategies can reduce machining time by up to 60%, and multiple part programming boosts productivity.

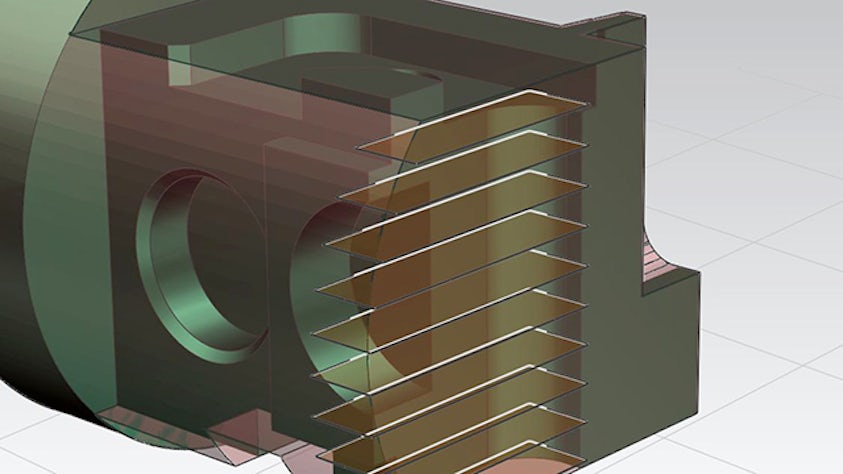

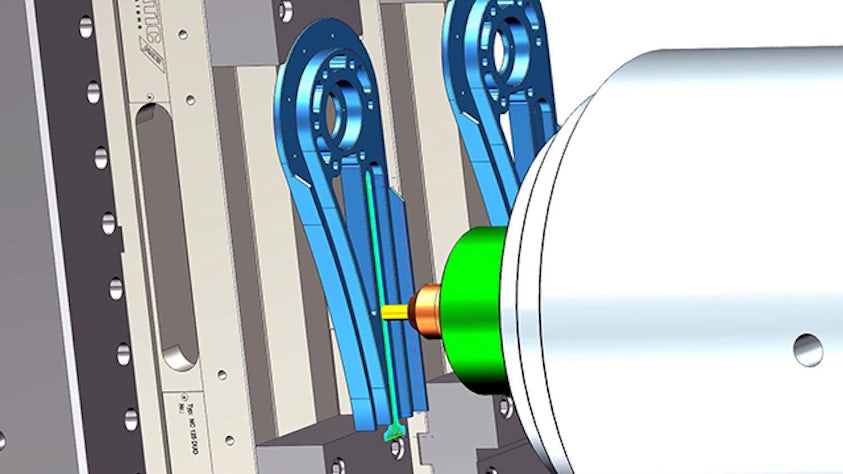

Turning: Effectively machine cylindrical parts on lathe machines with single and dual spindles using comprehensive turning capabilities. Roughing strategies include face, turn, back turn, bore and undercut operations, while finishing techniques encompass multiple-passes strategies and facing. Hole-making includes spot, drill, peck, chip, ream and tap operations, with grooving offering flexible tracking point control and threading for outer and inner diameters.

On-machine probing: Generate and visualize probing paths. Create on-machine probing cycles for milling and turning. Use output NC code with an integrated postprocessor. Simulate the process using the digital twin of the part, probe and machine tool. Detect process variations to adjust machining parameters.

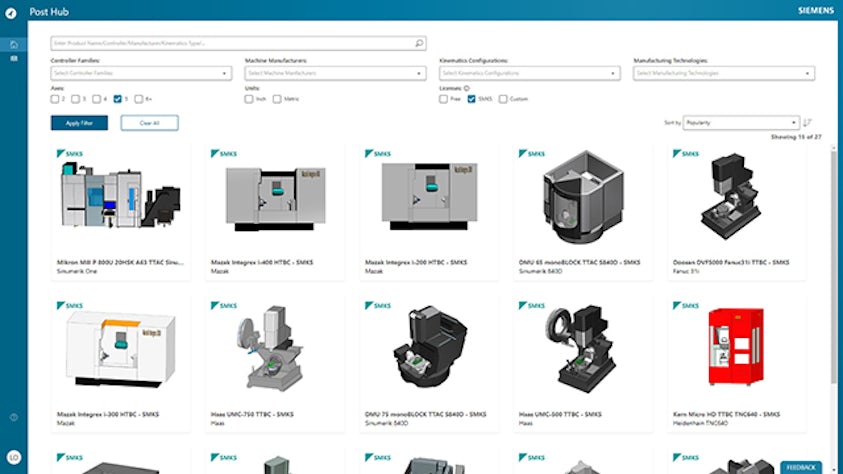

Simulation, postprocessing and shop documentation: Use toolpath animation and a postprocessor to generate production-ready G-code. Post Hub, a cloud-based library with over 1,000 postprocessors, and Post Configurator allow modification or creation of new postprocessors; machine tool builder and work instruction tools create kinematics models and develop associative work instructions.

Integrated CAD tools: NX CAM provides industry-leading CAD capabilities for modeling, editing and assembly, which speed up CNC programming. Using the integrated translators, you can read all the standard data formats, including IGES, DXF, STEP, STL and JT.

Manufacturing metrics are based on internal test machining or internal comparison studies.

Benefits of NX X Manufacturing:

- Program using advanced CAD/CAM tools tailored to your specific manufacturing needs

- Reduce upfront costs and streamline deployment with cloud technology

- Increase productivity with industry-leading CNC programming capabilities

- Improve collaboration among stakeholders using cloud-based solutions

- Expand the functionality of your solutions with Value Based Licensing

Customizable solution

Expand the functionality with NX X Manufacturing Value Based Licensing to configure and customize your solutions, including:

- Advanced modeling tools

- Specialized machining capabilities

- G-code-driven simulation

- Modern postprocessing solution