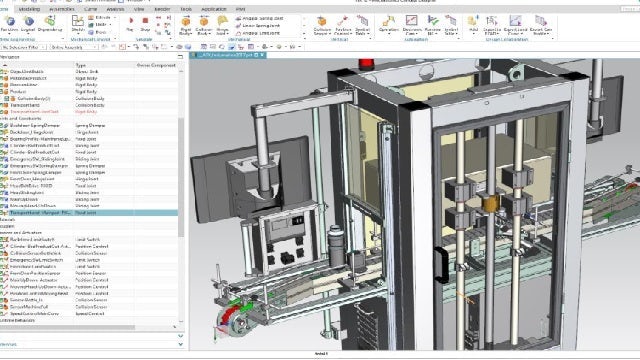

Interoperabilidad del software NX CAD

El software NX CAD goza de gran prestigio por su sólida interoperabilidad, es decir, por su capacidad de funcionar sin problemas con diferentes aplicaciones de software, sistemas y formatos de datos. Esta característica resulta crucial en los actuales entornos de desarrollo de productos multidisciplinares, colaborativos y cada vez más digitales.

Aprovechar el software NX CAD proporciona ventajas significativas, como el intercambio de datos sin fisuras, la integración con otras aplicaciones de software y plataformas, y la colaboración interdisciplinar y global. Es compatible con una amplia gama de estándares y formatos de archivo, se integra con los sistemas PLM, CAM, CAE e IoT, y ofrece amplias funcionalidades de personalización y automatización. Con NX CAD, puedes mantener la flexibilidad, optimizar los flujos de trabajo y mejorar la colaboración en tus complejos entornos de desarrollo de productos.

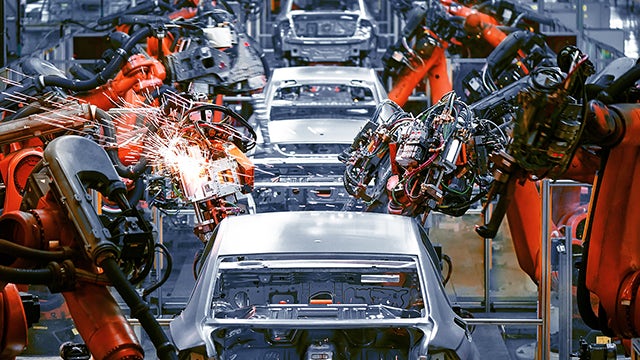

Ventajas del diseño asistido por ordenador (CAD)

El software de diseño asistido por ordenador (CAD) ofrece numerosas ventajas en diversos campos, como la ingeniería, la arquitectura, el diseño de productos y la fabricación. Con las herramientas digitales para crear, modificar, analizar y optimizar diseños, aprovechar el software CAD mejora tu eficiencia, precisión, colaboración e innovación.

Con el software CAD, puedes obtener ventajas como una mayor precisión, una colaboración y visualización mejoradas, más creatividad y escalabilidad, ahorro de costes y tiempo, y una reducción de la repetición de trabajos. El software CAD te ayuda a conseguir una mayor calidad, coherencia y eficiencia en tus procesos de diseño. Esto lo convierte en una herramienta indispensable en los entornos modernos de ingeniería, arquitectura y fabricación.

Integración del software CAD/PLM

NX CAD se puede integrar con el software de gestión del ciclo de vida del producto (PLM). NX viene listo para usarse con herramientas para integrarse completamente con el software Teamcenter de Siemens, una de las soluciones PLM más potentes y utilizadas. Esta integración crea un entorno unificado que optimiza todo el proceso de desarrollo de productos, incluidos el diseño inicial, la fabricación y fases posteriores. La integración del software CAD con el software PLM ofrece ventajas sustanciales, como la gestión centralizada de datos, la mejora de la colaboración, la agilización de los flujos de trabajo, la mejora de la calidad del producto, la gestión eficiente de los cambios y la reducción del tiempo de comercialización. Con esta integración, puedes optimizar tus procesos de desarrollo de productos, reducir errores y costes e impulsar la innovación. Esta es una solución inestimable para industrias complejas y competitivas.

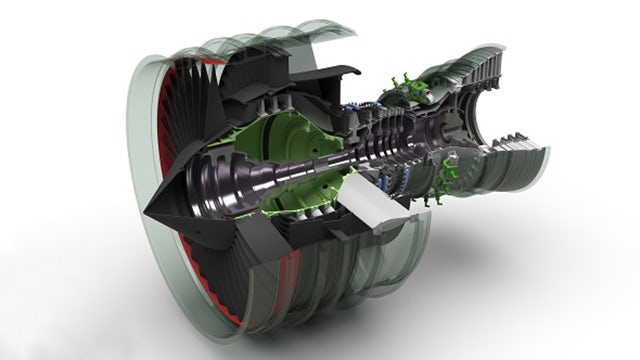

Gemelo digital y CAD

Utiliza NX CAD para crear, gestionar y aprovechar el gemelo digital más completo en todo el ciclo de vida del producto. Un gemelo digital es una representación virtual de un producto, proceso o sistema físico que permite la simulación, el análisis y la optimización en un entorno virtual.

Los datos de NX CAD se integran perfectamente con otras herramientas del portfolio de Siemens Xcelerator, como Teamcenter (PLM), Simcenter (simulación y pruebas), Insights Hub (IoT industrial) y Opcenter (sistema de ejecución de fabricación). Esta integración e interoperabilidad permiten a las empresas desarrollar, simular, validar y optimizar los gemelos digitales de forma efectiva. NX CAD se convierte en una plataforma líder para quienes buscan aprovechar la tecnología del gemelo digital para desarrollar y fabricar productos más inteligentes, eficientes e innovadores.