HEEDS acelera el proceso de desarrollo de productos automatizando los flujos de trabajo de análisis, maximizando los recursos informáticos de hardware y software disponibles, y explorando de forma eficaz el espacio de diseño para encontrar soluciones innovadoras al mismo tiempo que evalúa los nuevos conceptos para asegurar que se cumplan los requisitos de rendimiento.

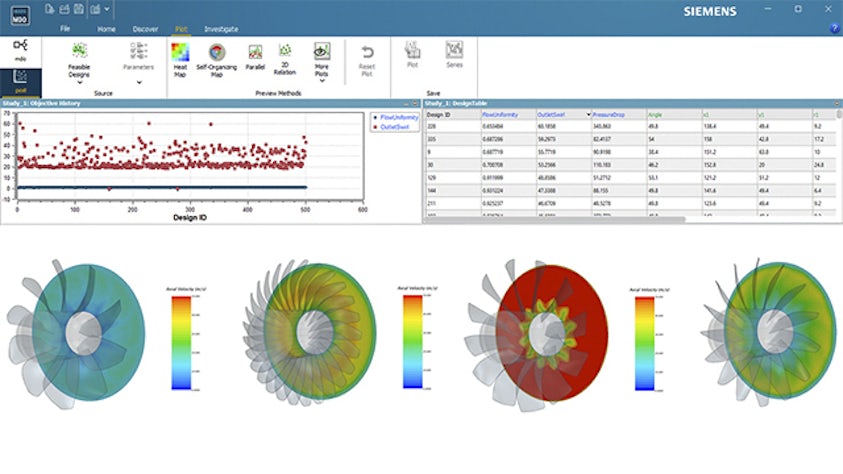

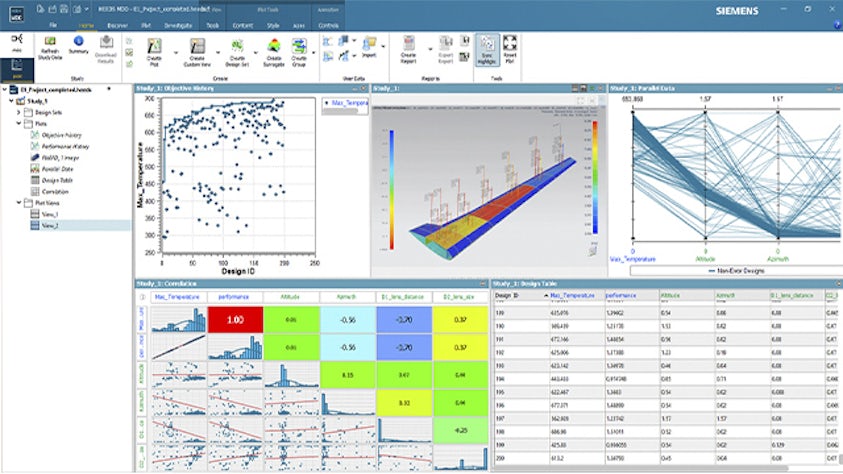

Exploración del espacio de diseño

HEEDS facilita la exploración eficiente y la optimización de las opciones y parámetros de diseño dentro del espacio de diseño, lo que permite a los ingenieros lograr resultados superiores con mayor facilidad y efectividad.

Eficiencia de tiempo y costes

Al automatizar el proceso de diseño y aprovechar los algoritmos de optimización, HEEDS ayuda a reducir el tiempo y el coste asociados al desarrollo de productos a través del análisis rápido de numerosas variaciones de diseño.

Optimización multidisciplinar

HEEDS admite la consideración de múltiples disciplinas de ingeniería de manera simultánea, lo que permite un enfoque integral para la optimización del diseño que considera las interacciones entre diferentes dominios.

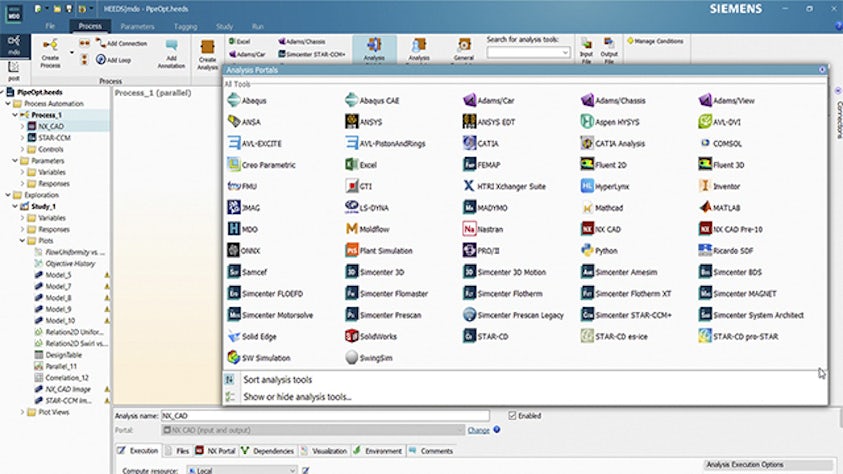

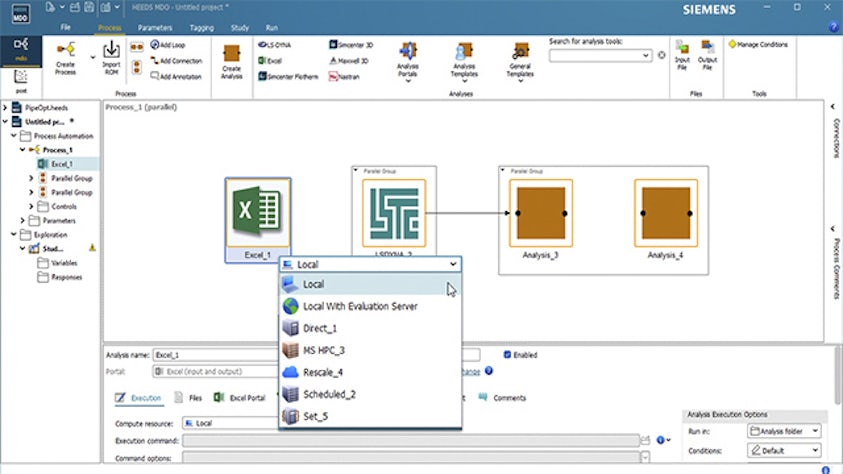

Automatización del flujo de trabajo

HEEDS automatiza las tareas repetitivas en el proceso de diseño y optimización, agilizando los flujos de trabajo y mejorando la eficiencia. Esta automatización puede conducir a una toma de decisiones más rápida y a una exploración más completa de los espacios de diseño.

Novedades de HEEDS 2410

HEEDS 2410 está diseñado para acelerar tu proceso de diseño con lo último en IA, solidez y mejoras de visualización para ayudarte a descubrir mejores diseños, ¡y mucho más rápido!