Crea progetti di componenti in lamiera

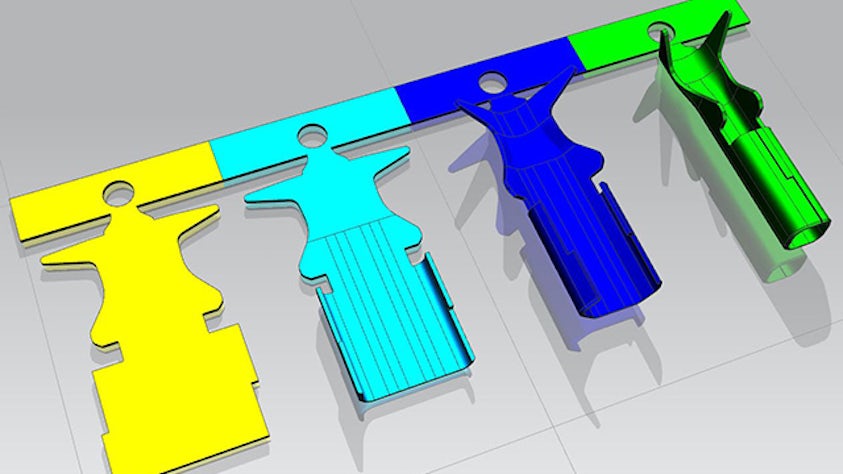

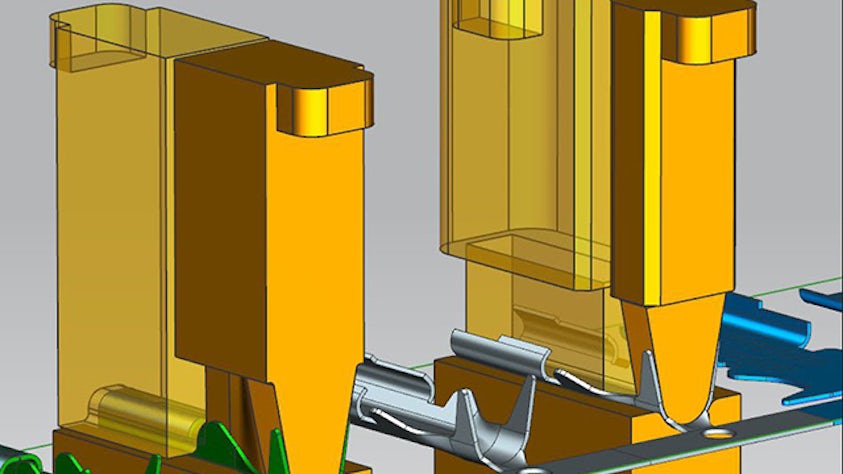

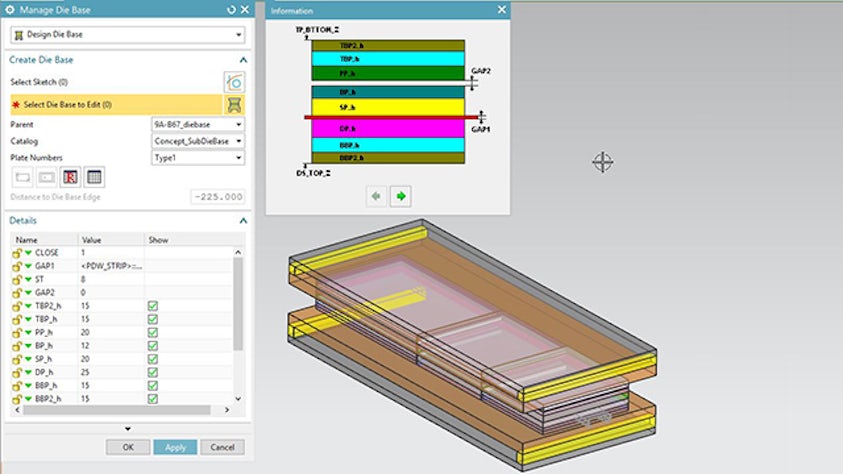

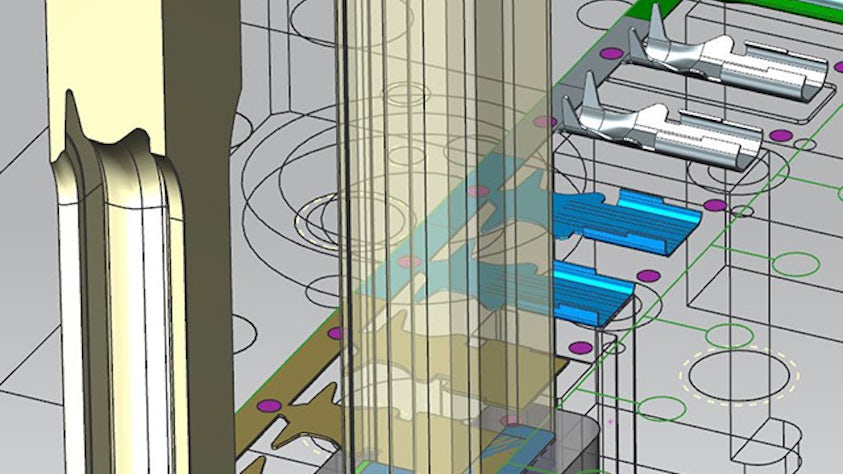

Ottimizza la progettazione di parti in lamiera a rottura diritta e a forma libera con un'ampia gamma di funzioni per lamiera. Sfrutta le funzionalità di riconoscimento delle feature, della tavola di piegatura e di dispiegamento diretto per progettare parti associative dello stadio intermedio con pieghe preliminari ed eccessive.

Applica la tecnologia One-Step Unforming and Formability Analysis per creare forme intermedie e forme vuote appiattite per parti a forma libera complesse.