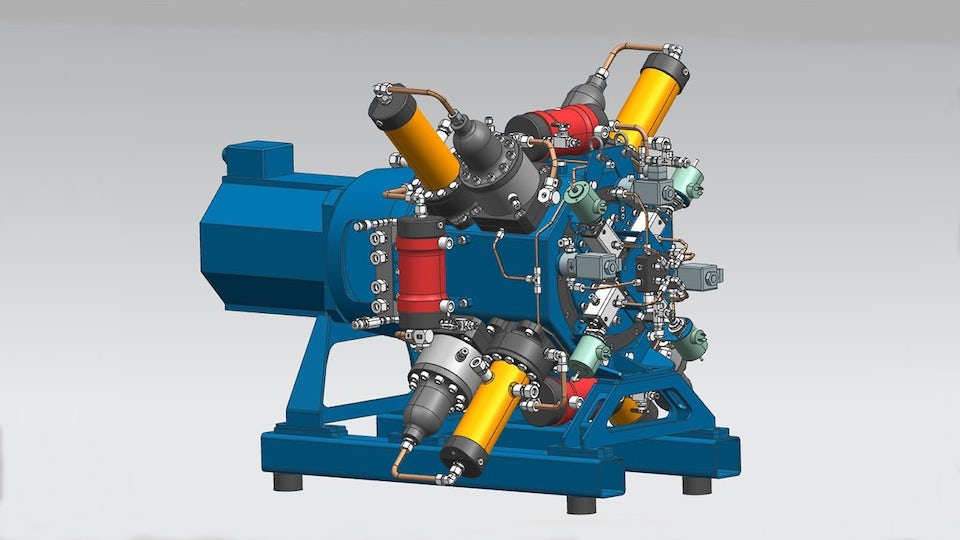

无需绘制 2D 图纸,同时确保最终产品符合其工程规范。借助 NX,产品团队可以在 3D 模型中捕获和共享工程需求,从而充分利用设计意图。

人们熟悉 2D 图纸并使用它们来定义成品。2D 工程图包含普遍理解和解释的标准符号。但是,在某些情况下,定义制造零件所需的多个冗余数据的存在可能会导致最终 3D 形状出现偏差。解释错误、重复错误或修订不一致可能会导致代价高昂的错误,这些错误会很快转化为较低的质量和生产效率。

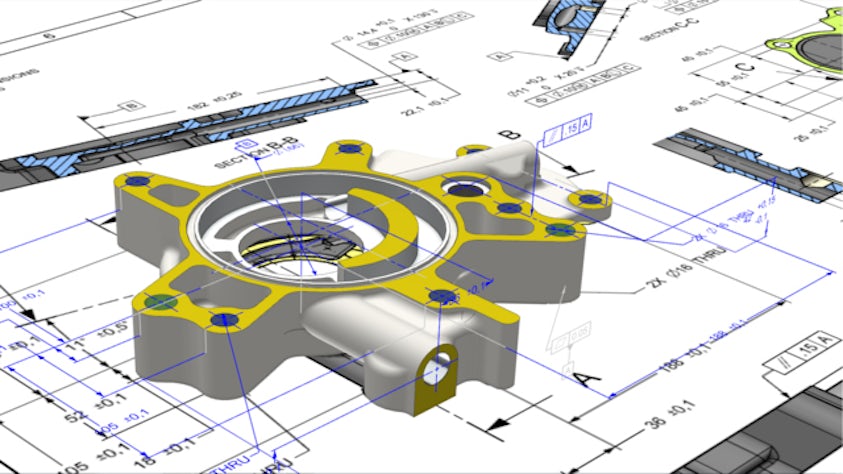

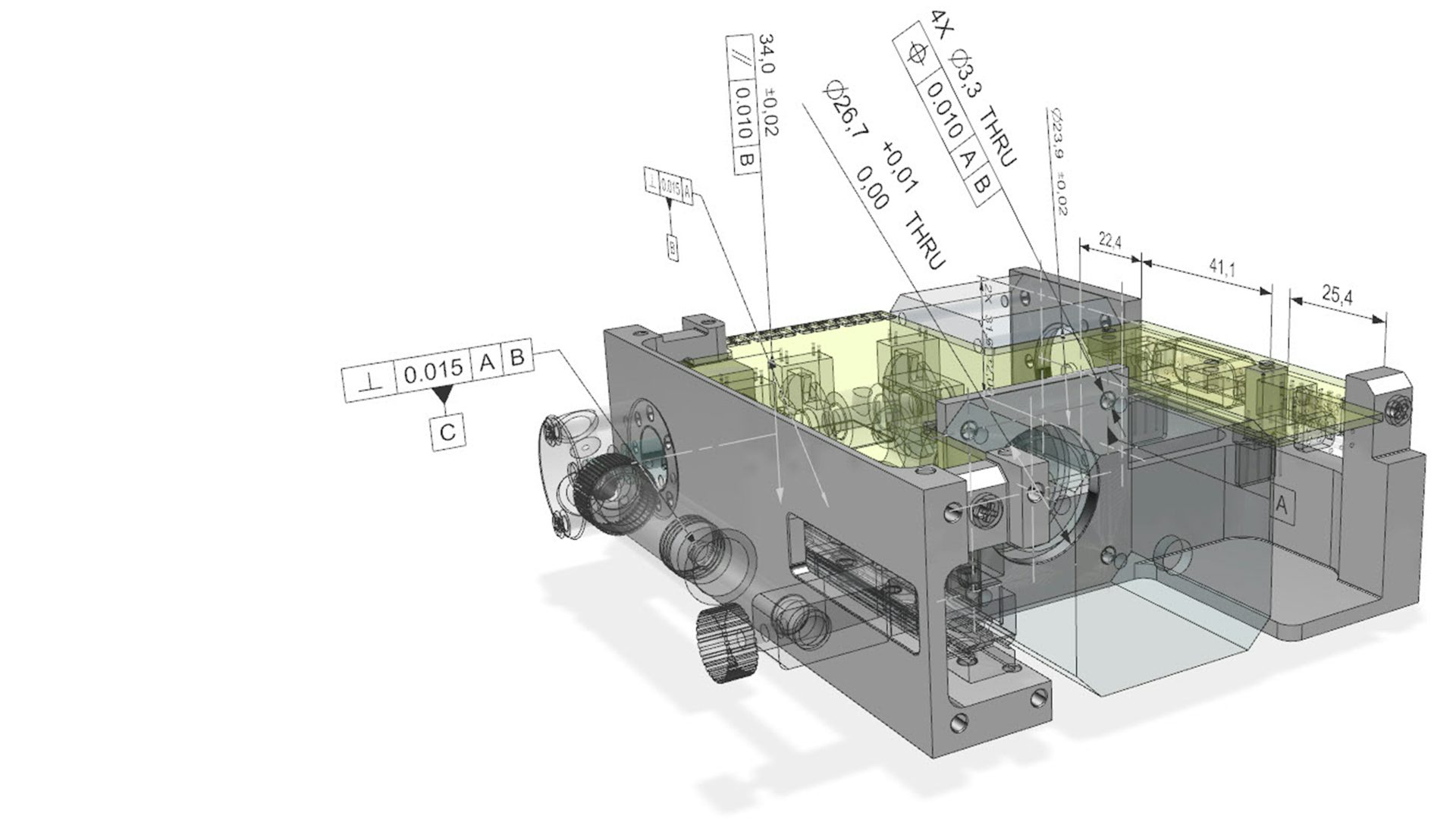

几何尺寸和公差是完整零件定义的重要组成部分。它影响产品实现的大多数领域,包括设计、工装、生产和检查。将 GDT 分别应用于 2D 零件视图和三维模型。使用 NX CAD 将 GDT 符号应用于 2D 零件视图和三维模型。

使用 2D 图纸来传达下游生产要求会给产品开发周期增加不必要的负担。产品定义一个简单的更改就要求更新 3D 数字数据,还要对产品相关的所有 2D 文档进行大量的工程改动。由于维护此文档需要时间,因此实施产品更改的生命周期会随着相关 2D 数据的增加而增长。