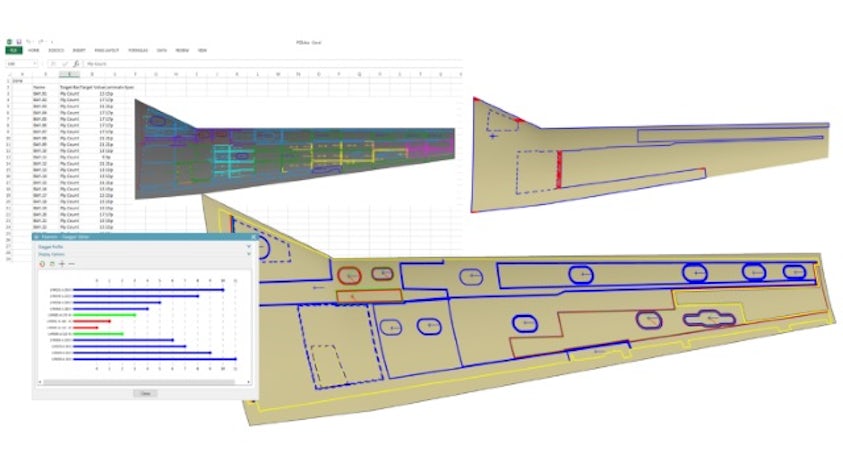

高效适应变化,同时提供待制造复合材料零件的精确仿真。我们的软件功能丰富,可以用作复合材料零件设计的中心,从而高效输入来自 CAE 的需求以创建可快速响应形状和规格变化的 CAD 数字孪生,同时提供连通车间的窗口以确保设计的可生产性。设计规则提供了强大的自动化功能,能够以尽可能少的几何输入创建铺层边界。此外,高级排序、过滤和重命名功能为管理复杂的现代复合材料零件提供了高效的工具。

Fibersim 支持使用特定于零件的方法来设计高级复合材料结构。这些方法可以针对不同行业加以专业应用,无论是汽车、航空航天、能源还是其他依赖复合材料的行业。

为了进行全面优化,高级复合材料部件需要独特的分析、设计和制造工作流程。Fibersim 是行业领先的软件,可以为专业工作流程提供支持以开发先进的复合材料。它支持并行工程,可在制造环境中执行分析和设计,而这正是开发高性能、低成本设计的关键。

先进的复合材料需要大量的分析和设计迭代,仔细考虑零件的独特重量影响。Fibersim 可与 Simcenter 和其他 CAE 系统紧密集成,在设计师和分析师之间提供双向更新的同时兼顾制造限制。

它还提供用于先进复合材料制造的设计。无论采用手工铺设、铺带、纤维铺放还是编织等制造工艺,Fibersim 都能在设计发布之前确保设计的完全可制造性。

Fibersim 的开放式多 CAD 架构在 NX、CATIA 和 CREO 中提供了这些专业的工程设计功能。Fibersim 还可将复合材料设计的详细层压结构保存到 Teamcenter 中,以便在企业内共享。