多领域系统仿真

在全生命周期内运用热流体或机电系统的数字孪生尽可能地提高投资回报率。您可以重用在工程阶段创建的模型并将其作为可执行的数字孪生,为采购、调试和运行提供有效支持。

执行基于成本的设计优化,尽可能地减少资本和运营支出,有力支持采购运营。在构建系统之前,将系统的数字孪生连接到虚拟可编程逻辑控制器,以验证它们在安全的虚拟环境中的交互。最后,通过工业物联网将可执行的数字孪生连接到真实的系统传感器和控制器,即可增加操作员的可用信息,以尽可能地提高系统操作的效率和安全性。

为了尽可能地提高性能、可持续性和成本效益,产品和工艺必须能够适应其环境和操作条件的变化。通过快速仿真模型将真实系统与虚拟表示相连接,获得实时准确洞察。

开发详细的数字孪生模型以复制真实世界的行为,并使用降阶建模 (ROM) 和人工智能 (AI) 等实时方法打包为独立模型。

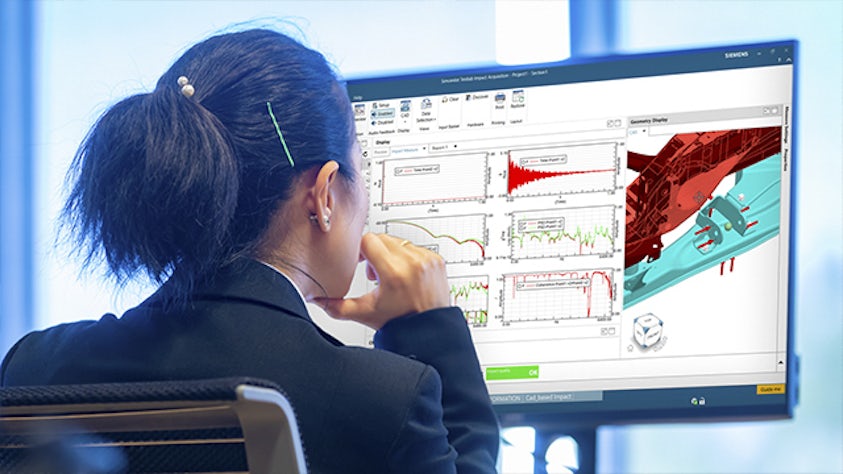

数字孪生是预测真实行为的物理系统的虚拟模型。Simcenter 提供跨领域构建这些模型的工具,可增强预测能力。

开发详细的数字孪生模型后,即可在互联的边缘设备或云端进行部署,开始将物联网 (IoT) 数据转化为可行的见解,从而实现实时调整并提高运营效率。

通过结合了软件、硬件和服务的 Siemens Xcelerator 平台,现实世界和虚拟世界得以无缝集成。阅读有关可执行数字孪生打包、部署和运作功能的更多信息。

在全生命周期内运用热流体或机电系统的数字孪生尽可能地提高投资回报率。您可以重用在工程阶段创建的模型并将其作为可执行的数字孪生,为采购、调试和运行提供有效支持。

执行基于成本的设计优化,尽可能地减少资本和运营支出,有力支持采购运营。在构建系统之前,将系统的数字孪生连接到虚拟可编程逻辑控制器,以验证它们在安全的虚拟环境中的交互。最后,通过工业物联网将可执行的数字孪生连接到真实的系统传感器和控制器,即可增加操作员的可用信息,以尽可能地提高系统操作的效率和安全性。

Simcenter 3D 支持基于结构分析创建智能虚拟传感器。在某些情况下,物理传感器不能用于测量临界位置。这正是 Simcenter 3D 智能虚拟传感技术的优势所在。其设计主旨就在于克服传统传感方法的局限性。 通过将有限的物理测量与降阶有限元模型 (FEM) 相结合,它创建的虚拟传感器可提供远远超出传统方法的见解。

Simcentder 支持在直观界面中创建降阶模型,提供机器学习、线性代数和统计学领域的一流简化技术。

ROM 的内存占用小,与工具无关,可以实时运作。它可以在产品生命周期的所有阶段用作可执行数字孪生,从而做出更好的决策并改善卓越运营。

通过自动化编创工作流程、高效探索设计空间和促进发现优化解决方案,加速可执行数字孪生开发过程。HEEDS 是实现快速决策过程和综合优化方法的理想伴侣,该方法考虑了不同领域之间的相互作用。

将可执行数字孪生添加到实时 (RT) 平台(例如车辆仿真器),解锁全新外部模型集成。这可帮助您更准确地反映车辆对驾驶员输入的实际物理反应。可与其他多物理场模型集成,并与 RT 仿真器和硬件在环 (HiL) 结合使用。重用现有模型,或使用之前简化的模型增加自由度 (DOF),以提高 RT 模型精度。

边缘计算直接在操作系统上提供数据处理功能。这样可以进行实时分析并加快决策速度,从而优化生产和运营并避免停机。边缘计算开启了在物理系统上运行可执行数字孪生的可能性,使其响应速度更快、效率更高。

关键绩效指标 (KPI) 和来自可执行数字孪生的信息可以流式传输到云端,以便随时随地远程监控设备。基于云的监控系统提供持续的数据馈送,可以快速检测问题并实现整个机组范围的监控功能。

Mendix 是领先的低代码应用程序平台,可赋能任何人构建、集成和扩展应用程序。Mendix 平台以一流的云、商业和行业服务为充满活力的开发者社区赋能。

通过逼真的仿真预测资产和系统将如何相互交互以及与人员交互。通过虚拟调试优化自动化和控制策略,无风险地测试新方法,并为团队提供准确的操作员培训。

深入了解资产或系统的未来行为,以做出明智的决策。准确预测剩余使用寿命并优化能源性能。利用模型预测控制和工作点优化,尽可能地提高效率并降低成本。借助 Simcenter 可执行数字孪生,可以主动管理资产并实现理想性能。

了解资产或系统性能不佳的原因。获得关键的见解,以查明不平衡、流体系统故障和生产机器故障等问题。利用基于仿真的可执行数字孪生,最大限度地减少停机时间并优化性能。

根据实时资产运行状况主动安排维护。准确预测关键组件的剩余使用寿命并虚拟监控磨损情况。通过在运营中利用可执行的数字孪生来避免计划外停机并优化维护。