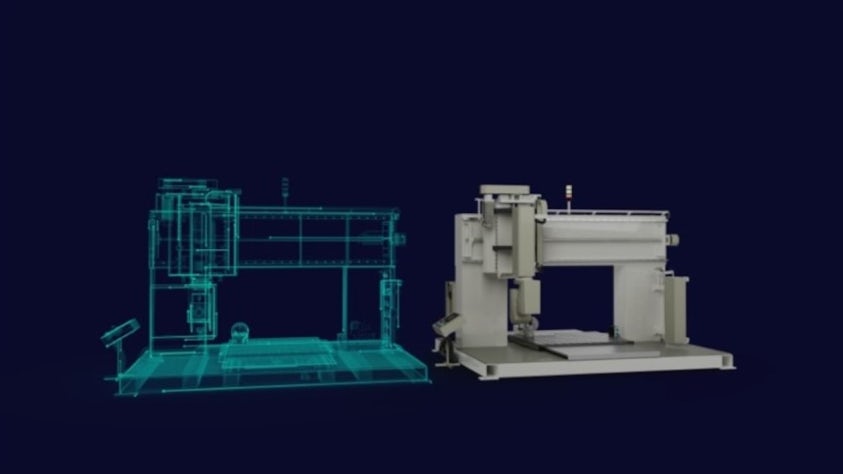

Create advanced machine designs with NX CAD by leveraging the comprehensive suite of integrated tools, enhancing both the efficiency and innovation of engineering projects. Rapidly iterate complex components and assemblies with powerful parametric and direct modeling.

NX CAD also supports advanced simulation capabilities, including motion analysis and stress analysis, enabling you to validate mechanical operations and assess the durability of designs under real-world conditions.

NX CAD seamlessly integrates with other Siemens software, which facilitates smooth data exchange and collaboration across teams, ensuring that all stakeholders stay aligned from conceptual design through to manufacturing.

Equipped with cutting-edge features specifically tailored for machine design - such as gear design and CAM functionalities - this award-winning software automates many routine tasks and generates machine-ready code, significantly reducing the time from design to production. You can utilize specialized toolsets and NX add-ons for sheet metal design, welding and routing of electrical wiring and piping, which are crucial for completing complex machinery projects. NX CAD tools not only expedite the design process but also enhance the precision and customization of the final product, allowing for innovative solutions tailored to specific operational requirements. With NX CAD, you have the technology at your fingertips to push the boundaries of what's possible in machine design, resulting in more efficient, robust and innovative machinery.