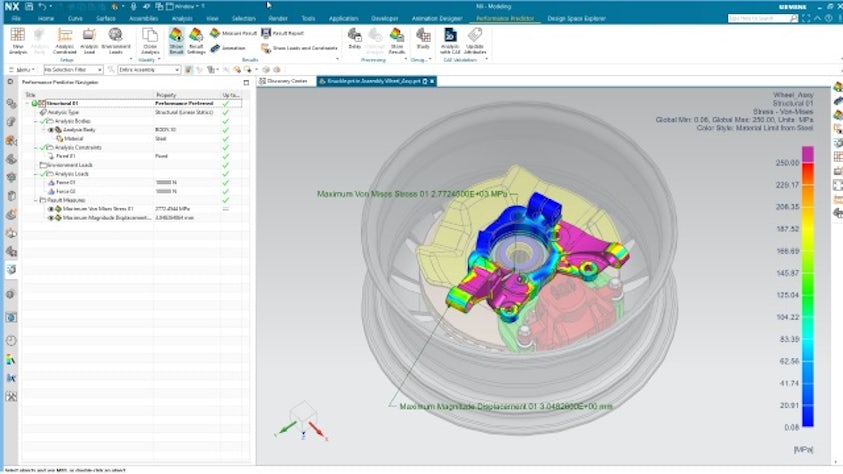

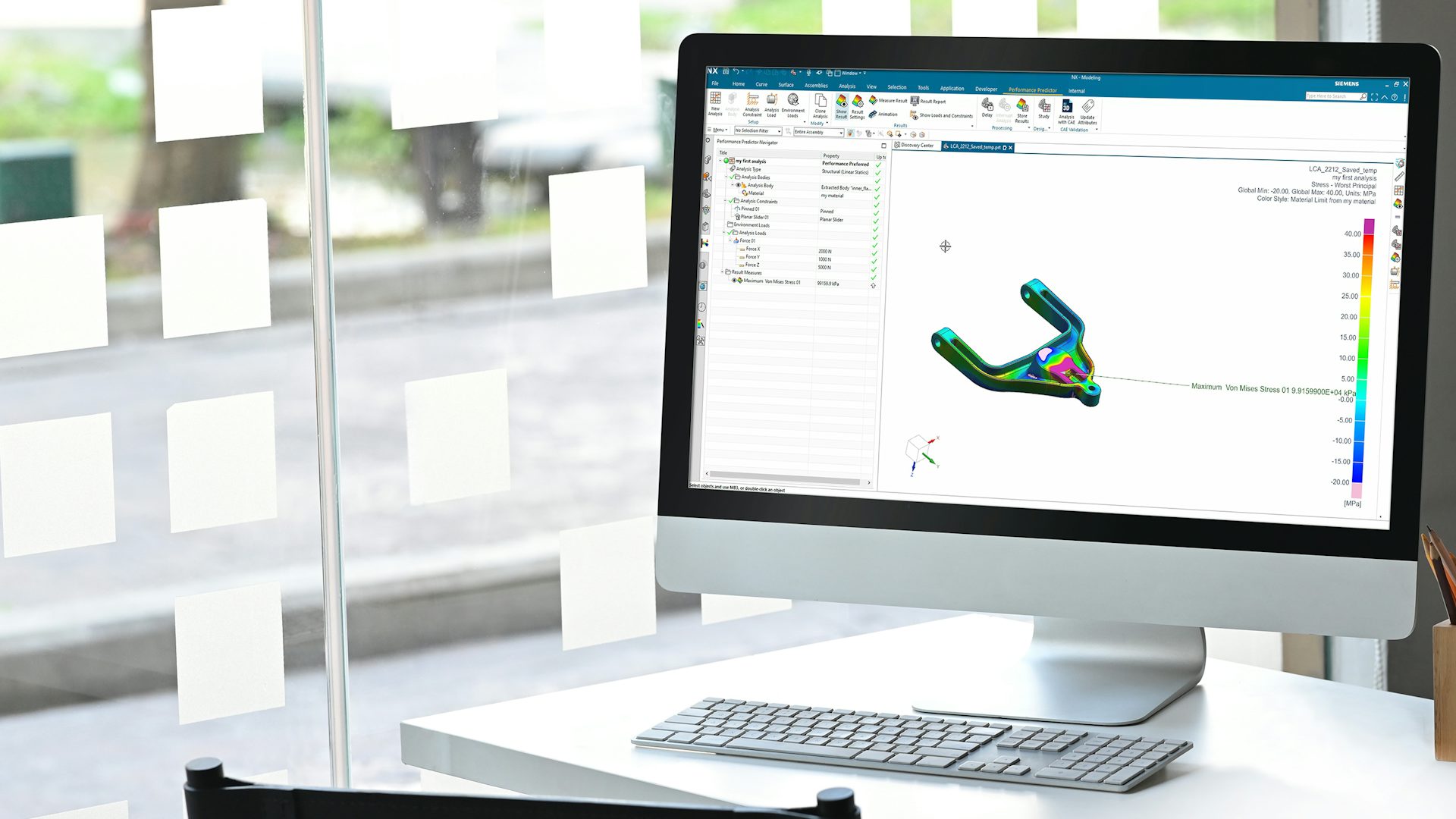

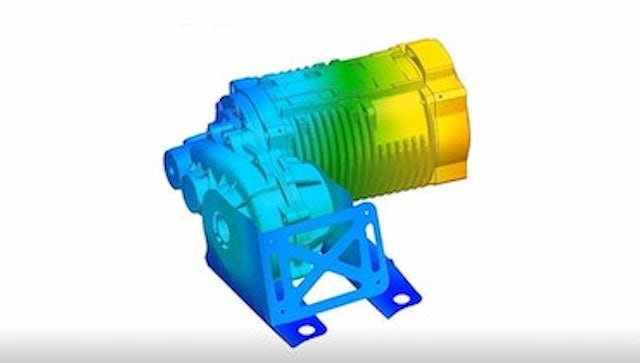

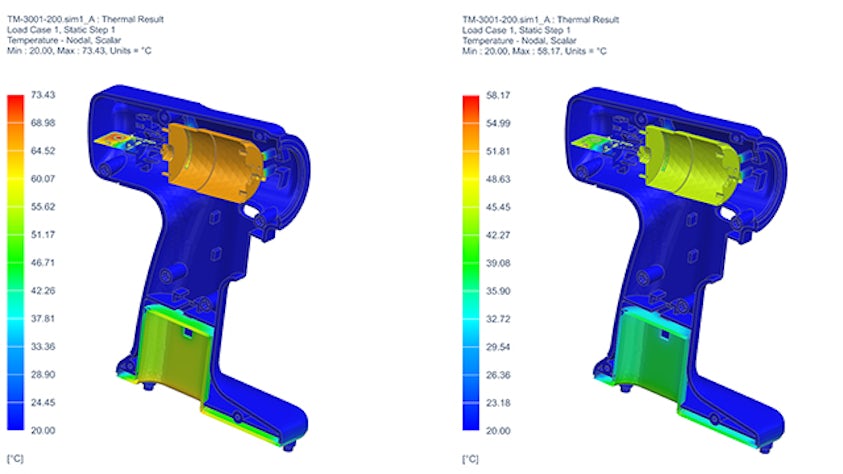

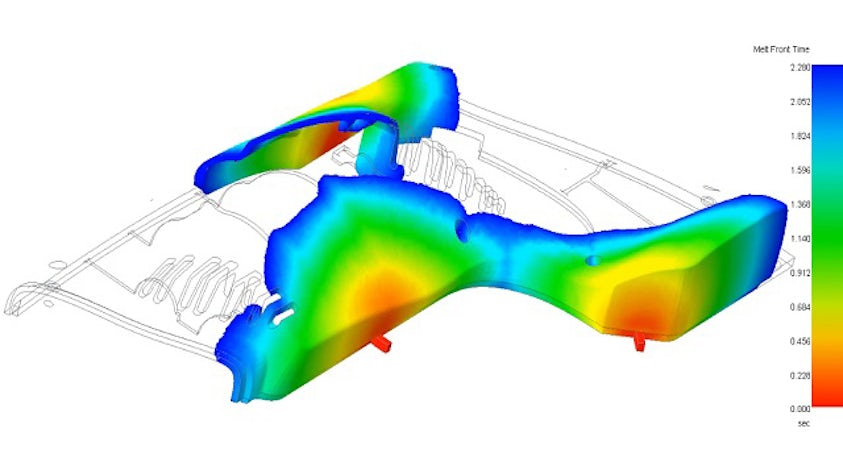

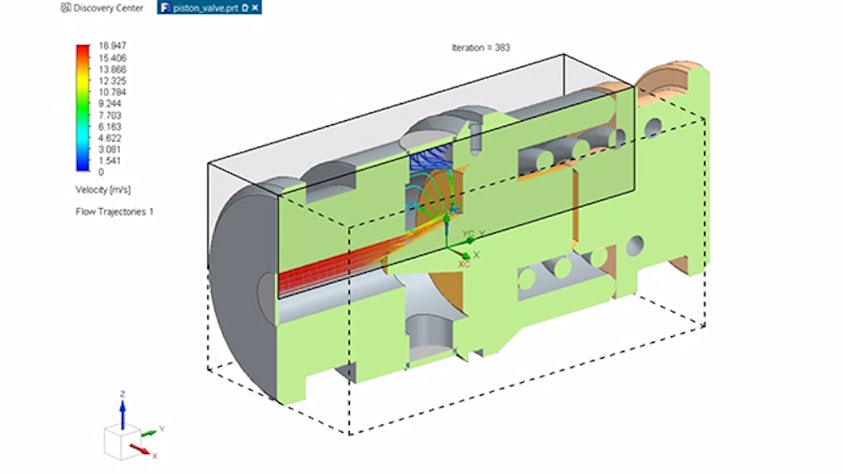

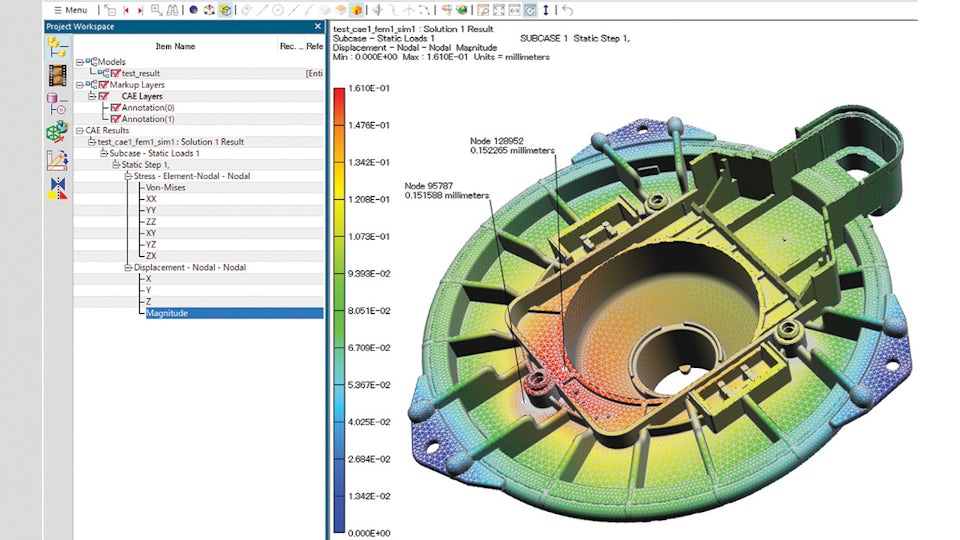

With the ability to accelerate the design exploration and optimization process by up to 90%, NX Performance Predictor enables NX designers to explore possible options faster than traditional tools and processes. NX Performance Predictor enables simulation-driven design earlier in the design cycle. Designers can conduct simple simulations, freeing up simulation engineers for more complex simulations. Your analysis is also linked with Simcenter 3D, meaning you can conduct an in-depth simulation of your part for validation, ready for manufacturing.

NX Performance Predictor enables you to simulate parts you create in real time while exploring different design and material choices. It enables designers to make the best decisions, while also enabling you to explore more concepts without prototypes and physical testing.