How to improve part quality with integrated software

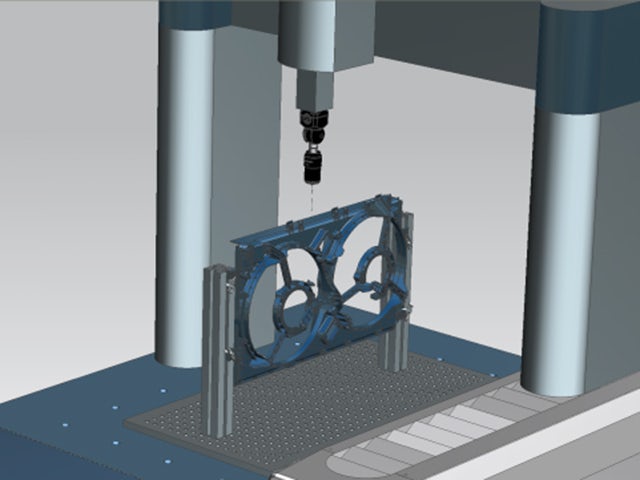

Digitalize your part quality control using a data-driven approach by integrating the coordinate measuring machine (CMM), inspection programming, shop floor execution and measured data analysis.

Read more about our advanced quality inspection capabilities:

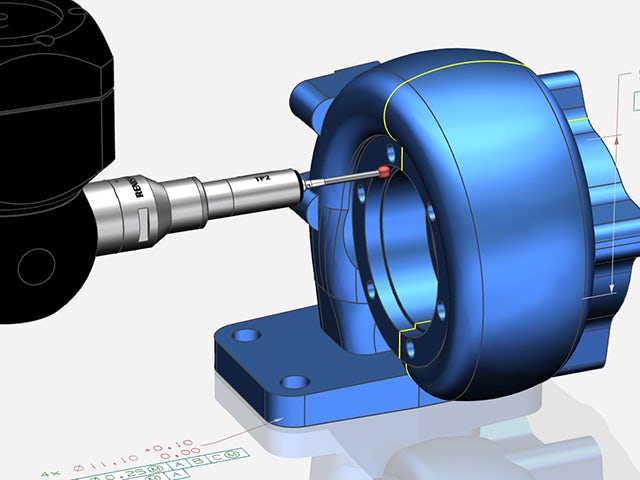

CMM inspection programming

Automatically generate and accurately simulate inspection paths with advanced capabilities in NX software.

Program the latest inspection methods with minimum input by using the part geometry and embedded product and manufacturing information (PMI).

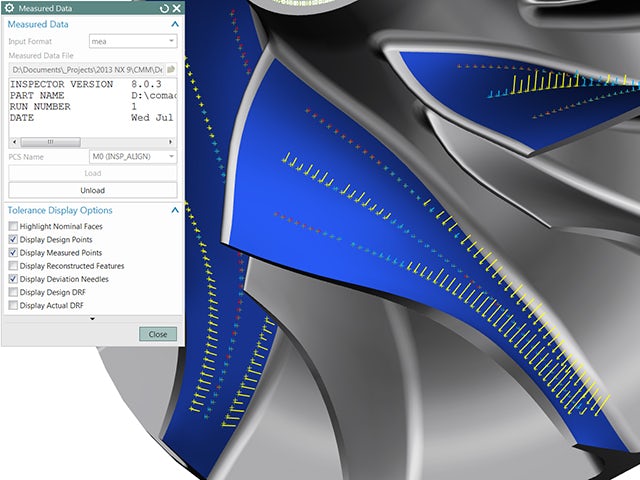

Inspection data analysis

Monitor the part quality by comparing as-built measured results against the as-designed 3D geometry.

Visualize the measurement results in NX and perform analysis in the context of the digital part model.

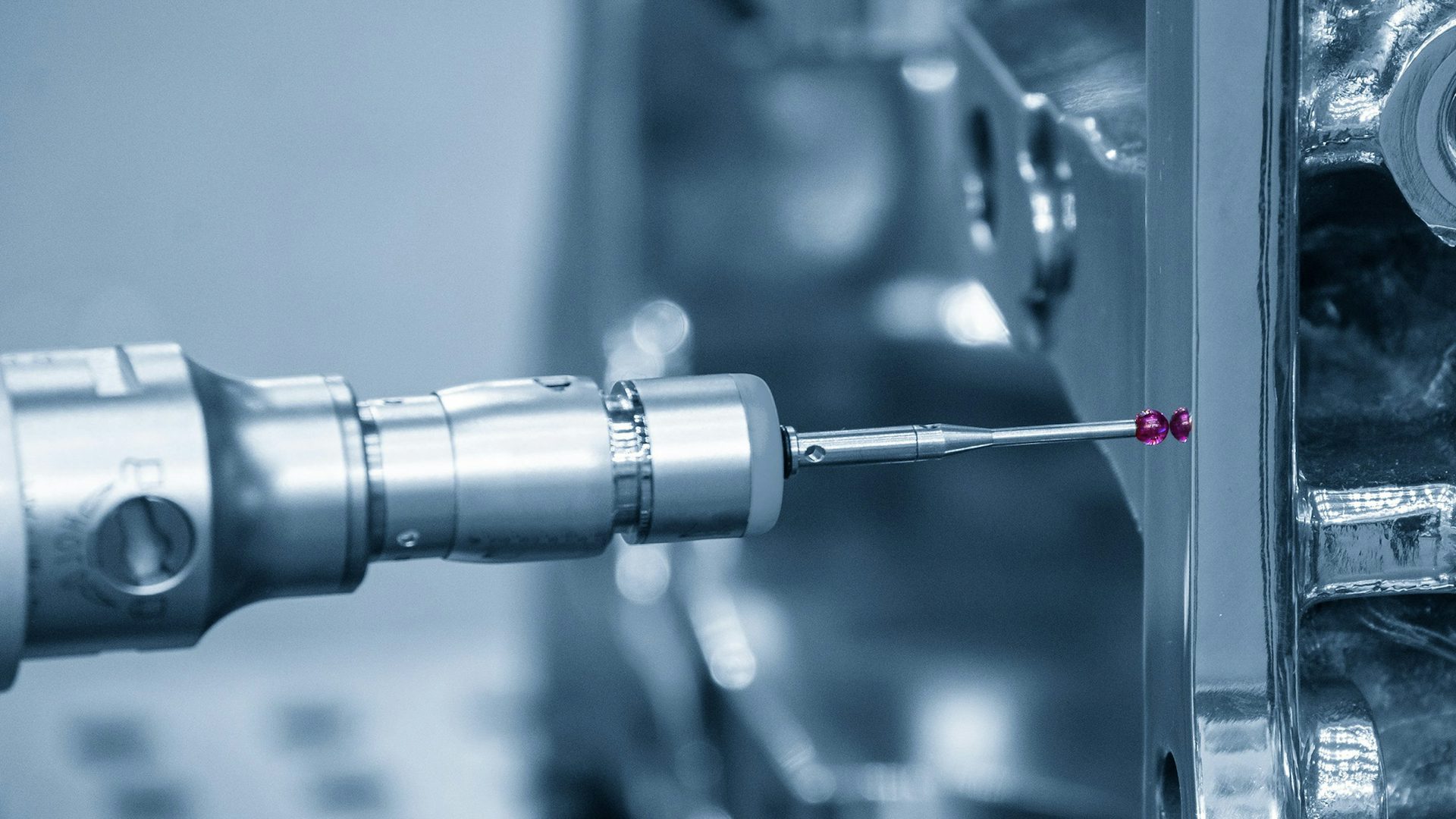

Inspection program execution

Run consistent and accurate in-process inspection and measured data analysis of manufactured parts using CMM equipment and inspection-ready CNC machines.

The closed-loop part quality control process helps you deliver precision components that meet the stringent requirements for quality and dimensional accuracy.

C-Mill

Precision part manufacturer integrates NX CMM Inspection Programming to digitalize the entire production operation

Company:C-Mill

Industry:Aerospace & defense, Medical devices & pharmaceuticals

Location:Port, Switzerland

Siemens Software:NX

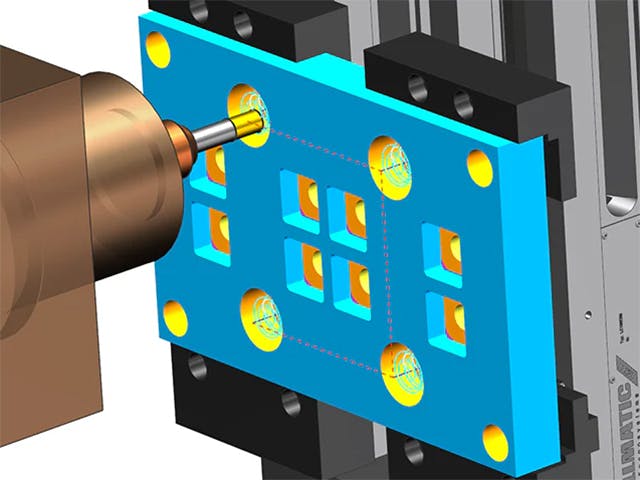

On-Machine Probing

Optimize machining accuracy with on-machine probing. Inspect parts, reduce setup time, and improve quality by adjusting machining parameters using adaptive control.

Automate in-process measurement to refine machining operations in real time, ensuring consistent part quality and precision.

Learn more about On-Machine Probing

Explore NX X Manufacturing products

Get more details about our wide range of cloud solutions for your specific part manufacturing needs.

Siemens Teamcenter Share

Optimize your entire production process with Teamcenter Share, a cloud-based collaboration solution, which seamlessly connects to NX CAM software. Securely communicate and share information with internal and external stakeholders in the cloud.

Connect design, manufacturing and shop floor teams to run more flexible and efficient production.