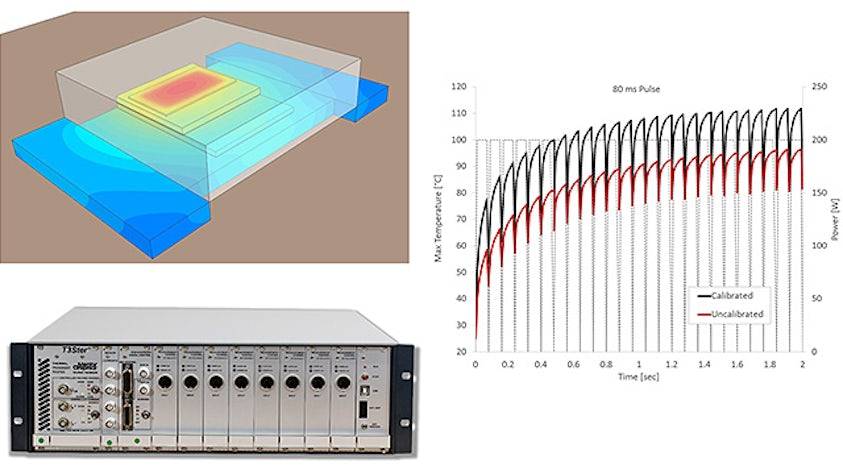

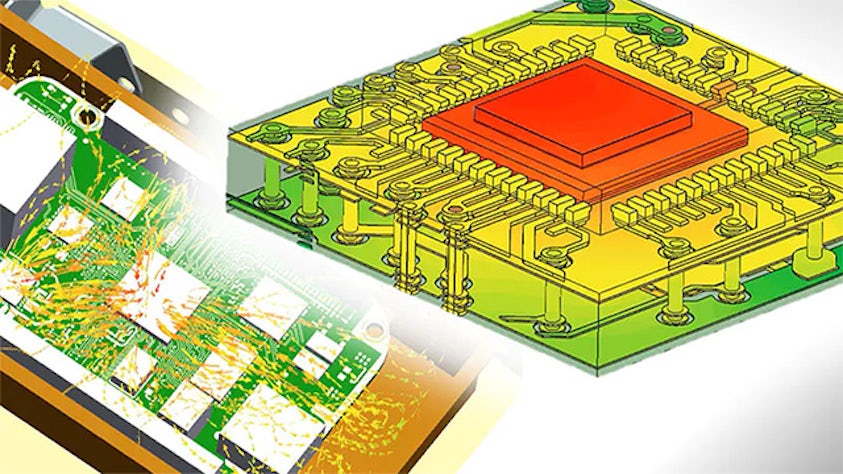

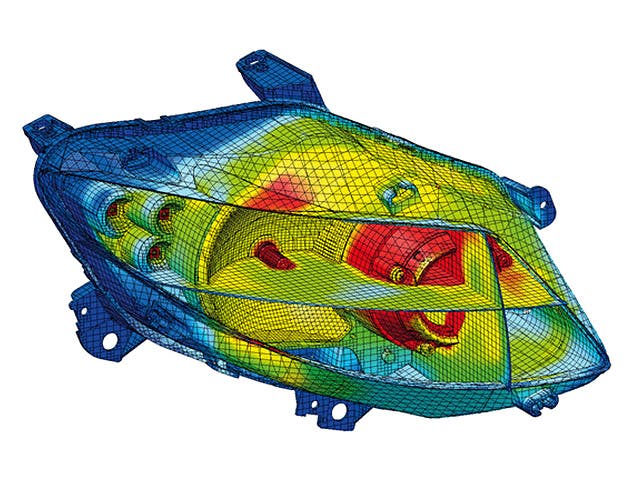

For semiconductor OEMs it is crucial to understand package structure influence on thermal behavior and reliability, especially with increasing power density and complexity in modern package development. Challenges such as those in complex system-on-a-chip (SoC) and 3D-IC (integrated circuit) development mean thermal design must be integral to package development. An ability to support the onward supply chain with thermal models and modeling advice that goes beyond datasheet values is of differentiated value in the market.

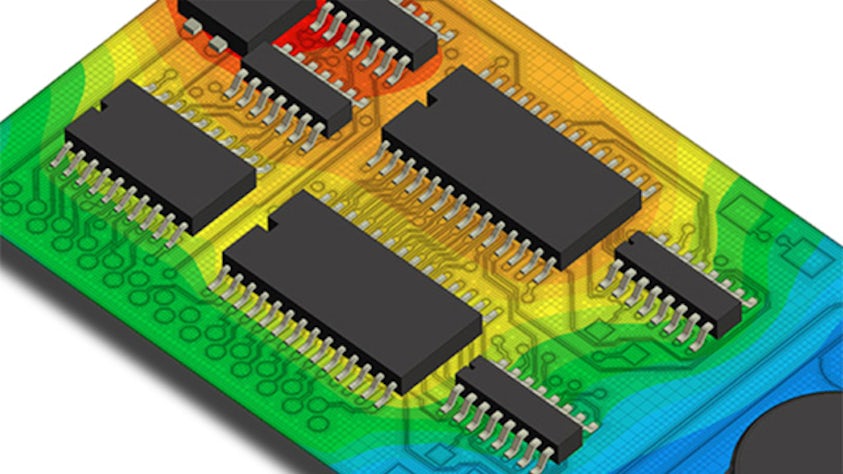

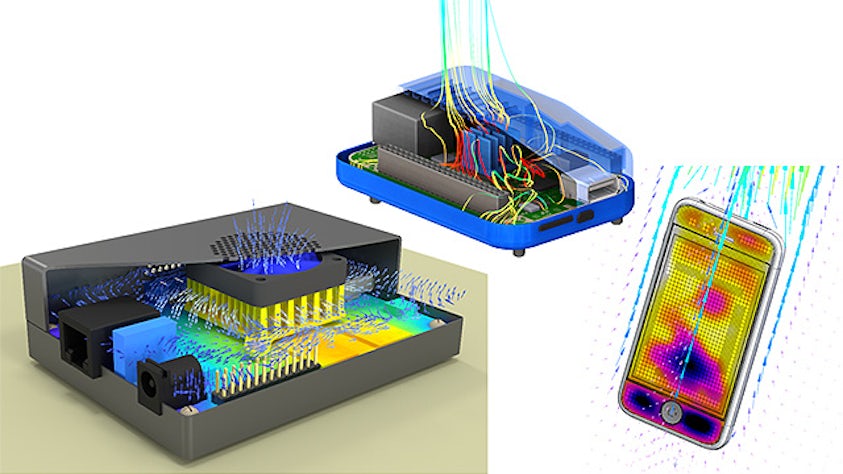

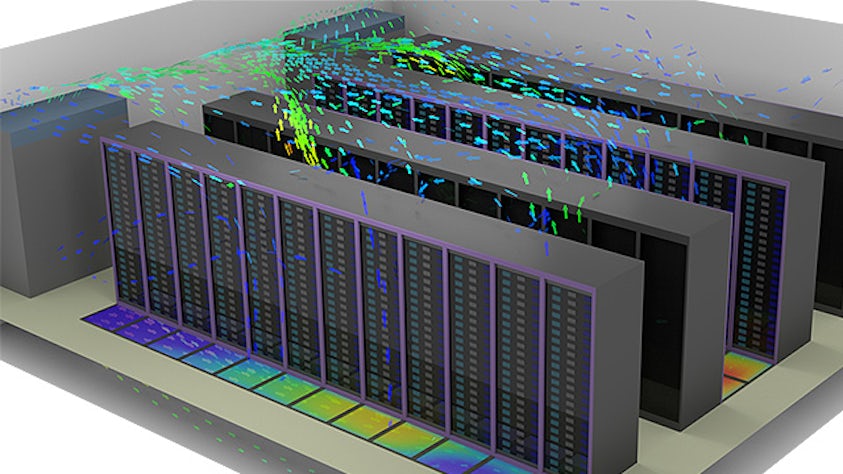

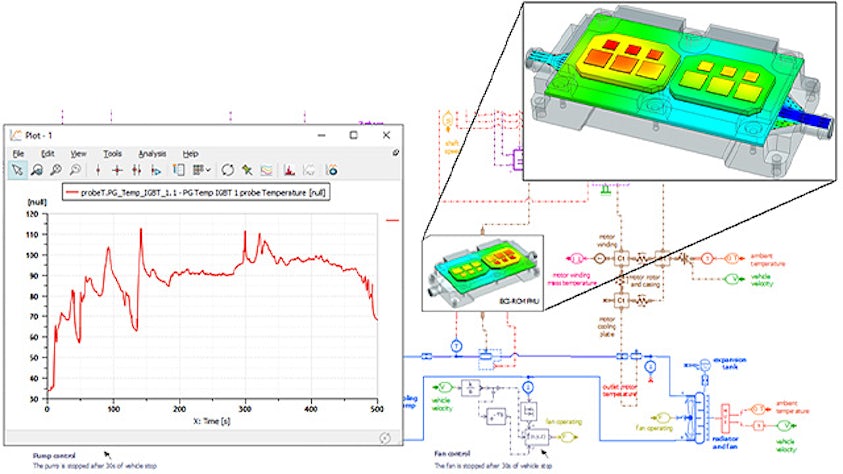

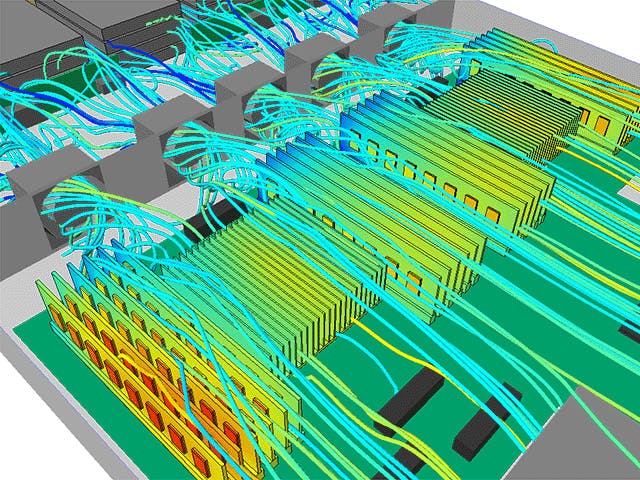

For electronics manufacturers integrating packaged ICs into products, it is important to be able to predict with accuracy the junction temperature of a component on a printed circuit board (PCB) within a system-level environment to develop appropriate thermal management designs that are cost effective. Electronics cooling simulation software tools provide that insight. It is desirable for thermal engineers to have options available for modeling fidelity of IC packages to suit different design stages and availability of information. For highest accuracy modeling of critical components in transient scenarios, a detailed thermal model is possible to calibrate to junction temperature transient measurement data automatically with Simcenter solutions.

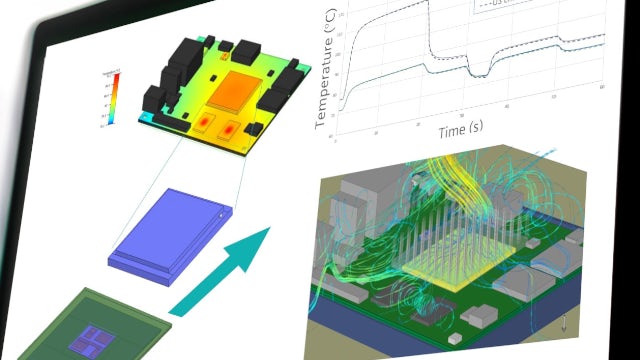

Explore IC package thermal simulation

- High density semiconductor package thermal development workflow – watch webinar