Start integrated. Stay integrated.

Integrate product architecture with system models, requirements and parameters inside product lifecycle management (PLM) to drive the entire product development process.

Author system models with a standard methodology

Stop the costly document-oriented spec-design-build cycle with a more collaborative way to create integrated product blueprints. System modeling, guided by an ISO standard systems methodology, captures product architecture, interfaces, requirements and parameters in one place. Integrating with PLM scales the process to enable continuous integration.

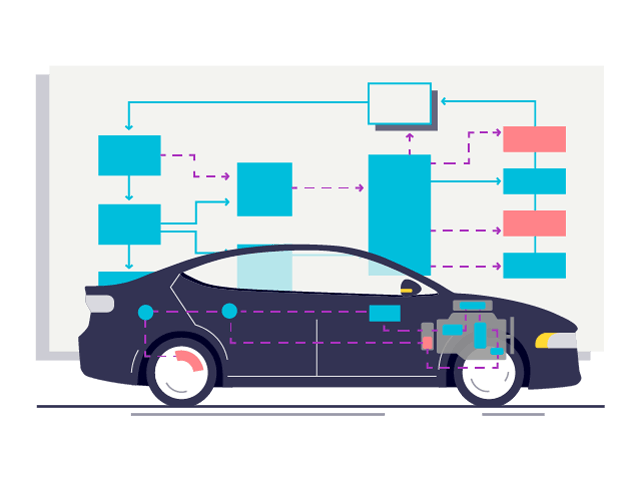

Manage product architecture with standard PLM services

Imagine a configured parameter tracing back to an architectural decision. System modeling with parameters, functions and interfaces participate in PLM services like configuration, change and workflow. This can also associate with a trade study, tied to requirements, downstream to parts, suppliers, simulations, processes, tests and more.

Continuous model-based collaboration with suppliers

Use supplier collaboration services to share portions of system models with suppliers while protecting your IP through integrated architecture inside PLM and SysML v2 compliance. Suppliers can continuously provide progress feedback for integration, thus creating model-based design chains (MBDC).