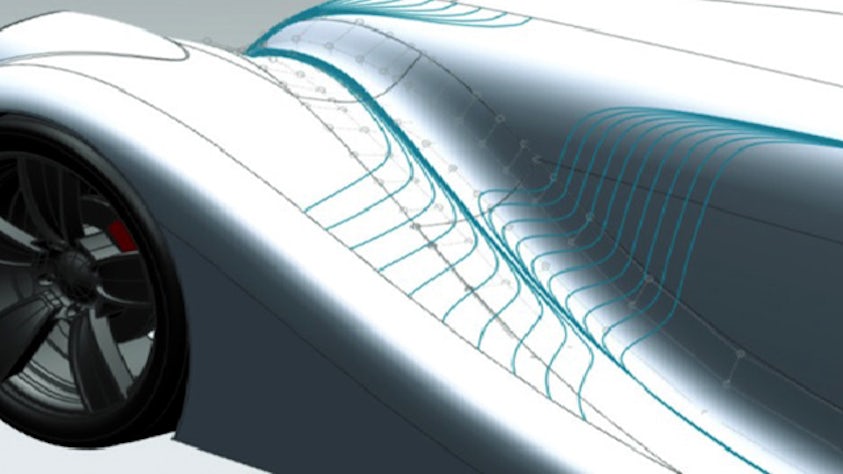

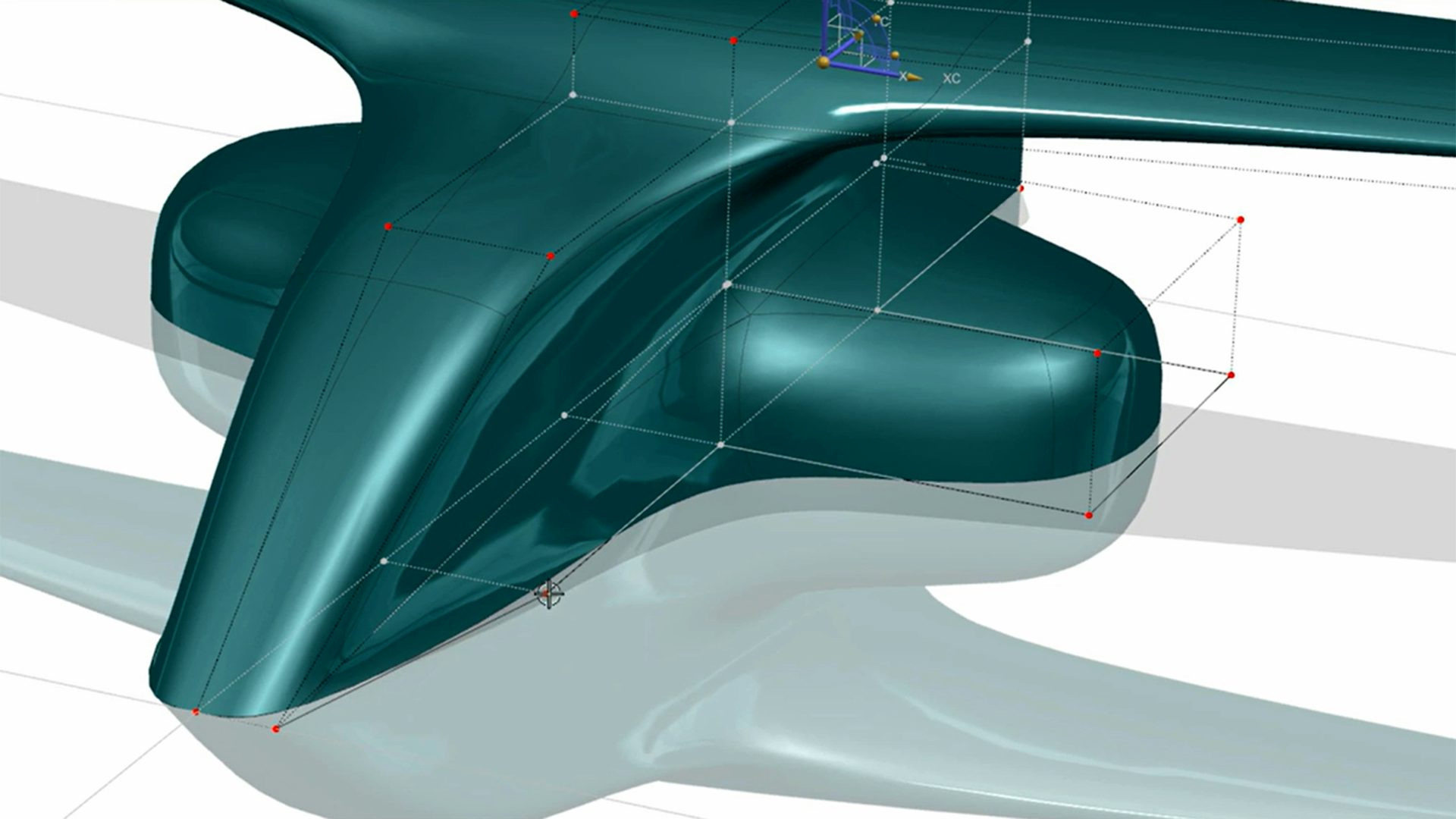

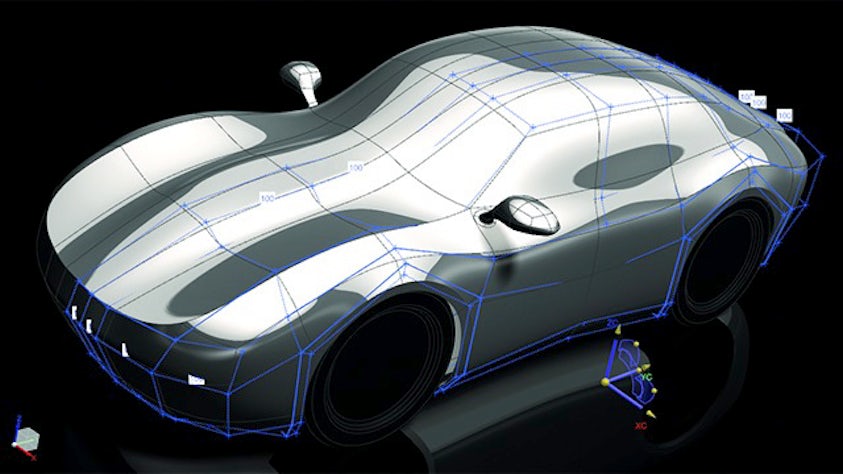

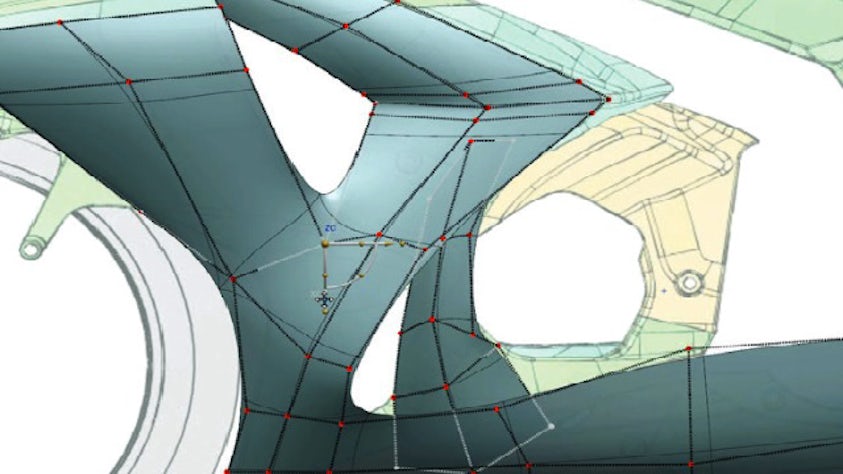

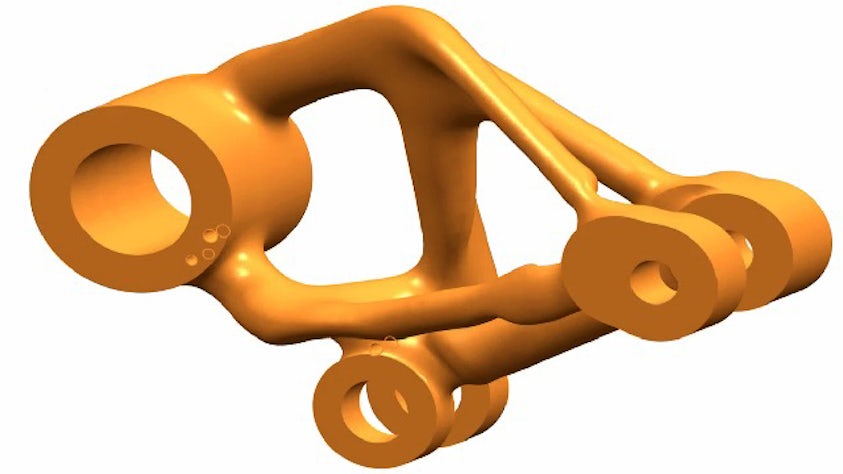

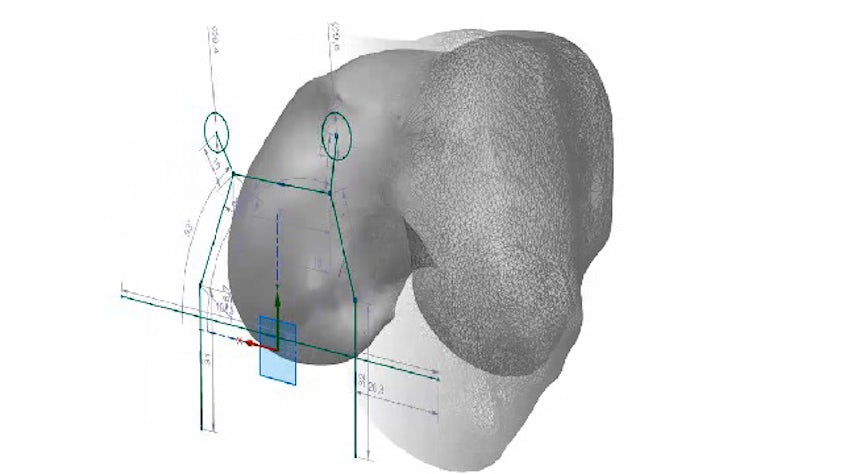

Evalúa la calidad analítica y visual de formas complejas con las funciones de análisis en tiempo real de NX. Las visualizaciones gráficas en tiempo real aceleran la evaluación y ayudan a orientar las modificaciones para mejorar la calidad de las formas.