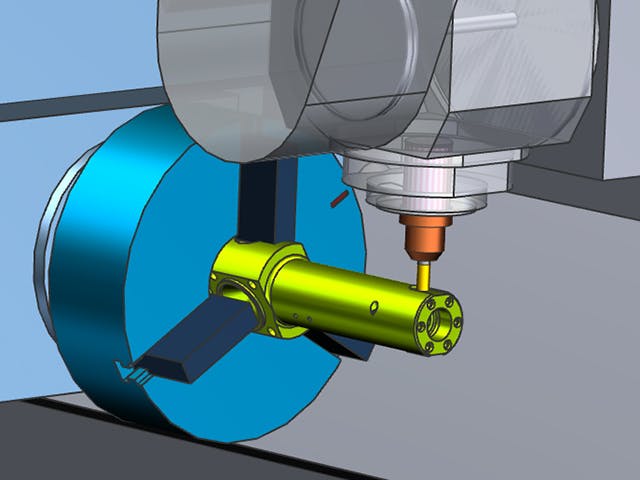

Aprovecha la solución de torneado flexible para programar rápidamente los trabajos más sencillos, así como las aplicaciones multihusillo y multitorreta más exigentes. Programa operaciones de torneado en los ejes A y B.

Programa operaciones de torneado avanzadas

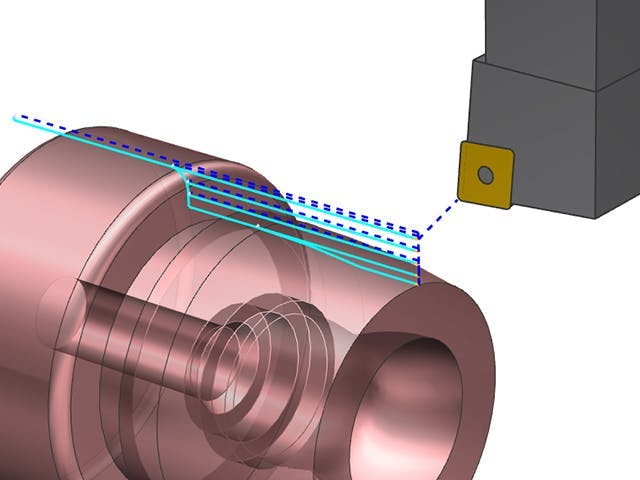

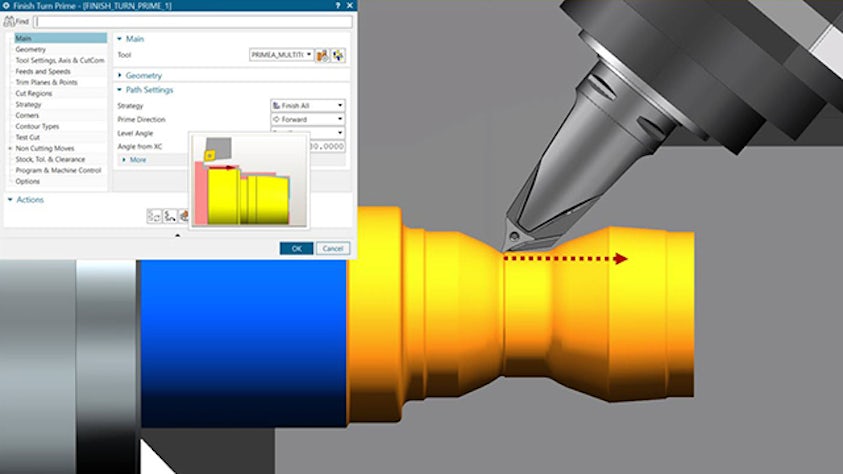

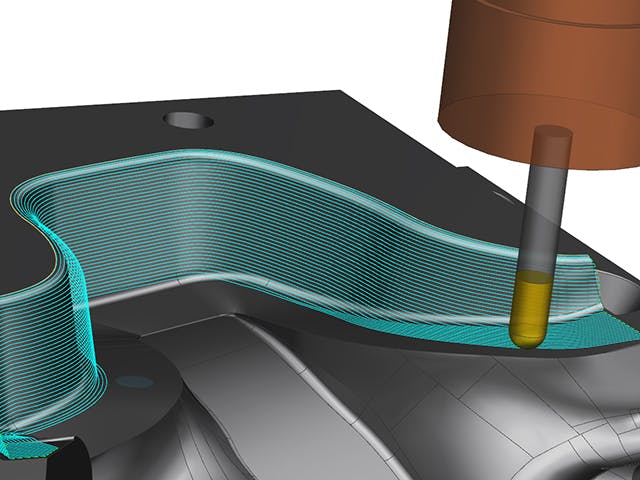

Puedes usar perfiles de piezas 2D o modelos sólidos completos para programar operaciones de desbaste, acabado en múltiples pasadas, ranurado cilíndrico, corte por hilo de ejecución y perforación de línea de centro. Los métodos de torneado innovadores, como PrimeTurning, pueden acelerar el mecanizado y mejorar la productividad hasta en un 50 %.

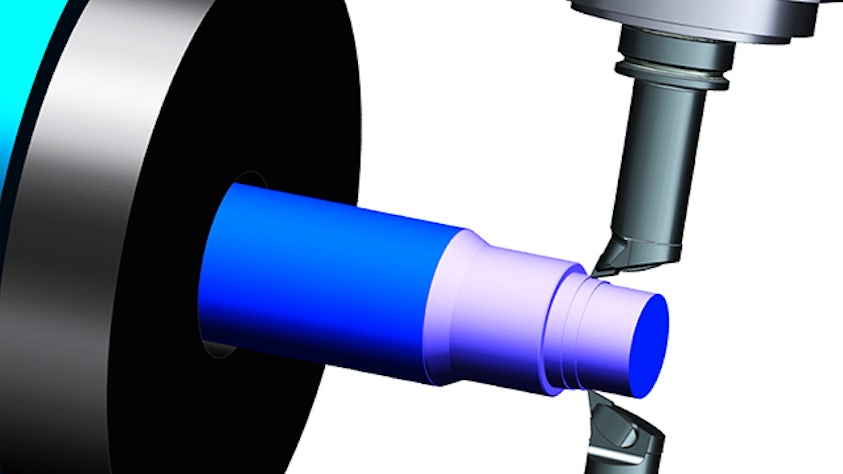

Controla automáticamente los volúmenes de torneado con la tecnología de pieza de trabajo en preparación (IPW), que permite la visualización en 3D y la gestión eficiente de los cambios de diseño.

Diseña con CAD integrado

Modela piezas, piezas en bruto, fijaciones y configuraciones de mecanizado completas utilizando CAD integrado para modelado y ensamble. Prepara modelos de piezas para la programación NC utilizando tecnología síncrona.

Genera programas validados

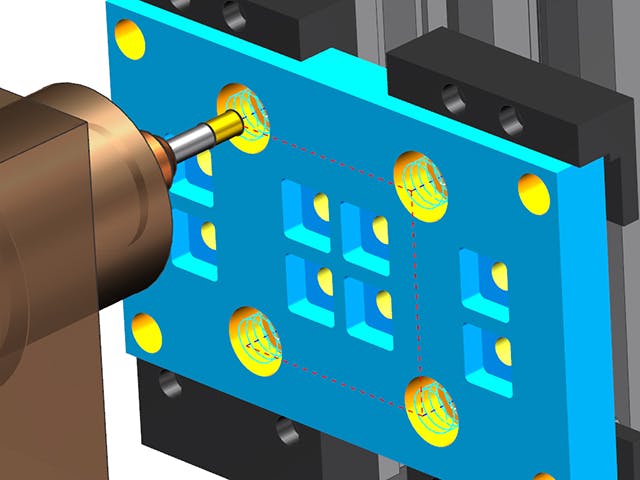

Genera programas NC validados y listos para producción utilizando la solución de posprocesamiento basada en la nube y la simulación de mecanizado integrada. Conecta digitalmente la planificación y la producción con la documentación de planta relacionada, incluidas las listas de herramientas y las hojas de configuración.

NX CAM proporciona funcionalidades de programación avanzadas para fresado, que incluyen:

- Desbastado: refrentado, torneado, torneado inverso, agujereado, agujereado inverso, segado

- Acabado: refrentado, torneado y agujereado

- Agujereado: punto, taladro profundo, rotura de viruta, mandrinado, roscado con macho

- Ranurado cilíndrico: con control de punto de seguimiento flexible

- Roscado de diámetro exterior/interior (OD/ID)

- Operaciones de salida y avance de herramienta

- PrimeTurning

- Torneado por pellizco

- Control de herramientas en los ejes A y B

- Pieza de trabajo en proceso

- Verificación de trayectorias de herramientas

- Posprocesamiento

Además, NX ofrece herramientas CAD integradas, como:

- Tecnología síncrona

- Ensambles

- Traductores CAD

- Modelado de formato libre

- Simulación de diseño

- Información de fabricación y producto (PMI)

- Dibujo de planos