대량 가공 라인의 계획 디지털화

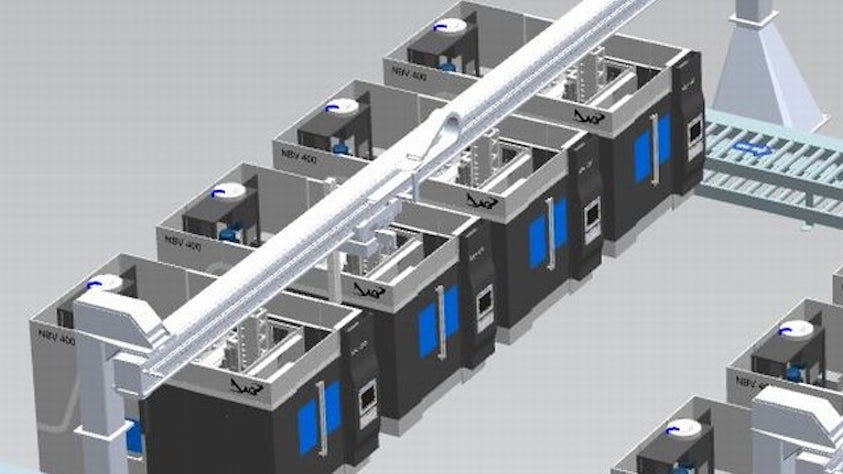

포괄적인 디지털 트윈을 사용하여 여러 기계 공구와 전달 라인 장치로 구성된 전체 가공 라인의 프로세스를 최적화할 수 있습니다.

계획 시간을 단축하고 자동차 및 기계 제조를 위한 대량 가공 라인의 처리량을 늘려 경쟁 우위를 확보할 수 있습니다.

포괄적인 디지털 트윈을 사용하여 여러 기계 공구와 전달 라인 장치로 구성된 전체 가공 라인의 프로세스를 최적화할 수 있습니다.

계획 시간을 단축하고 자동차 및 기계 제조를 위한 대량 가공 라인의 처리량을 늘려 경쟁 우위를 확보할 수 있습니다.

여러 설정 및 다기능 기계에서 작업을 분산, 균형 조정, 프로그래밍 및 시뮬레이션하여 최신 생산 가공 기술을 활용할 수 있습니다.

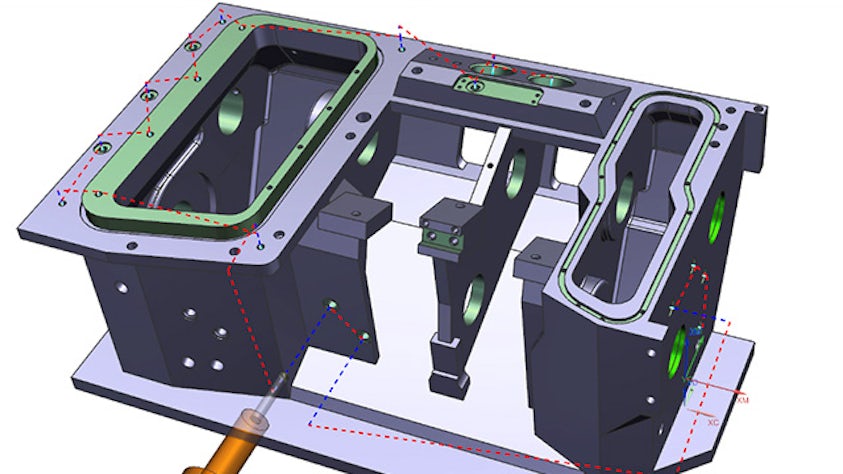

가공물의 공정 중 상태를 추적하고 밀링, 드릴링 및 선삭 작업 간에 원활하게 전송하여 전체 가공 프로세스를 정확하게 시각화할 수 있습니다.

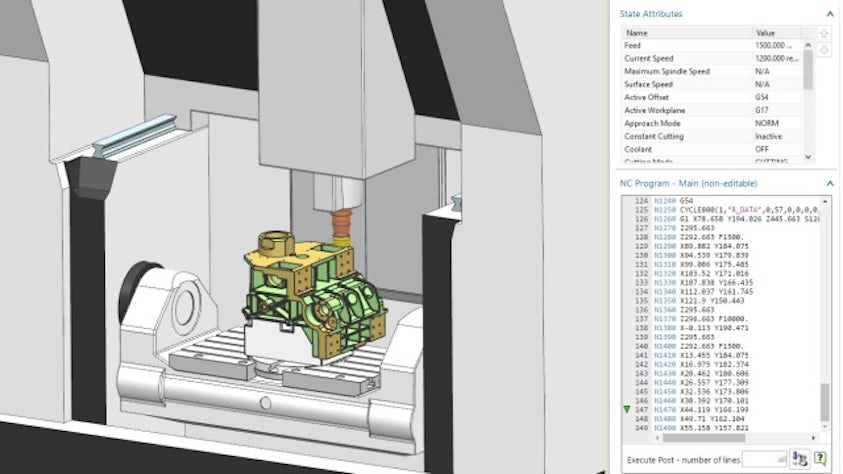

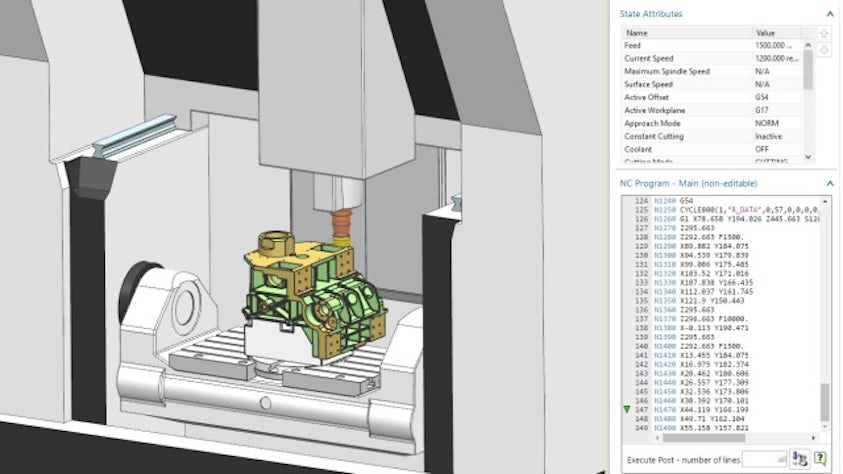

통합 CAM 소프트웨어로 상세한 NC 프로그래밍 및 기계 가공 시뮬레이션을 지원하여 프로그래밍과 라인 계획 간에 필요한 변경 사항을 쉽게 전달할 수 있습니다.

IPW(공정 중 가공물)를 포함한 기계 설정의 디지털 트윈으로 제조 현장에서 충돌 없는 가공을 보장할 수 있습니다. 자동화된 고급 NC 프로그래밍 기능을 활용하여 대량 가공을 위한 최적화되고 안전한 공구 경로를 신속하게 생성할 수 있습니다.

특정 파트 제조 요구사항에 적합한 다양한 클라우드 솔루션에 대해 자세히 알아보십시오.