Simcenter E-Machine Design 可通过其模板驱动的用户界面快速开发电机设计,从而减少开发时间和成本。

对复杂的问题进行建模 - 适当调整准确性

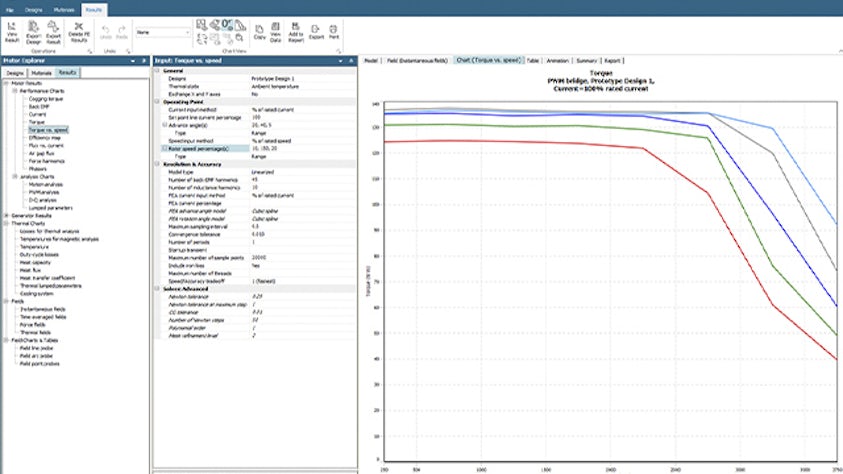

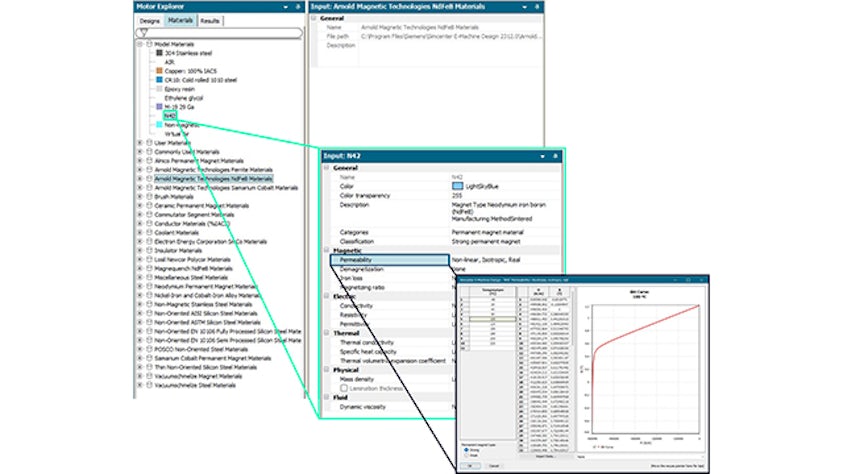

Simcenter E-Machine Design 是市面上为数不多的一款可在分析型 EMAG、校准分析型 EMAG 和有限元方法 [FEM] EMAG 实验中进行选择的软件;这种多功能性使您可以根据相应的设计阶段调整性能数据收集的准确性和时间。

加快速度 – 使用现成的模板

无需 FEM 专家,也无需设置模型、优化网格、定义和审查所需的实验等一系列复杂的流程。只需使用我们的模板驱动软件即可自动执行各种实验。

提出您的想法,对其进行明确定义并快速审查其性能,从而减少对多个物理原型的依赖。

探索各种可能性 – 全面解决方案

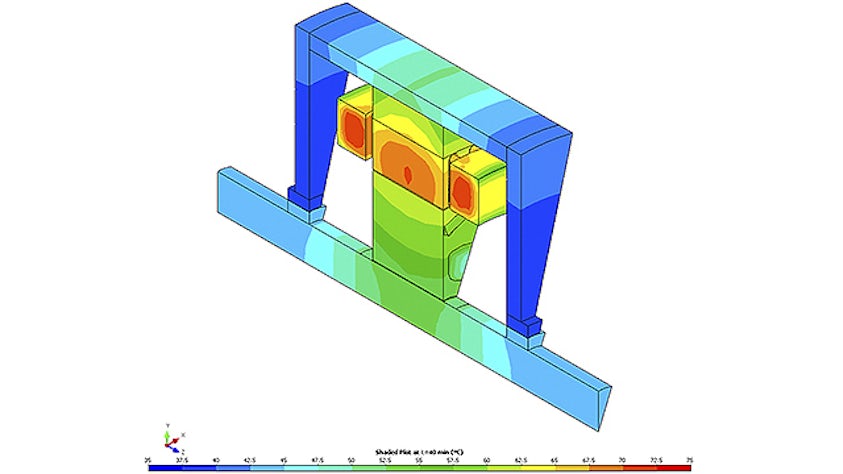

这是市面上为数不多的一款提供全面解决方案的产品,用于在“运行条件”下检查机器性能。您可从一开始就使用自动耦合的磁热效应,避免潜在故障。无需数据文件或几何交换即可获得耦合,从而消除潜在用户错误。

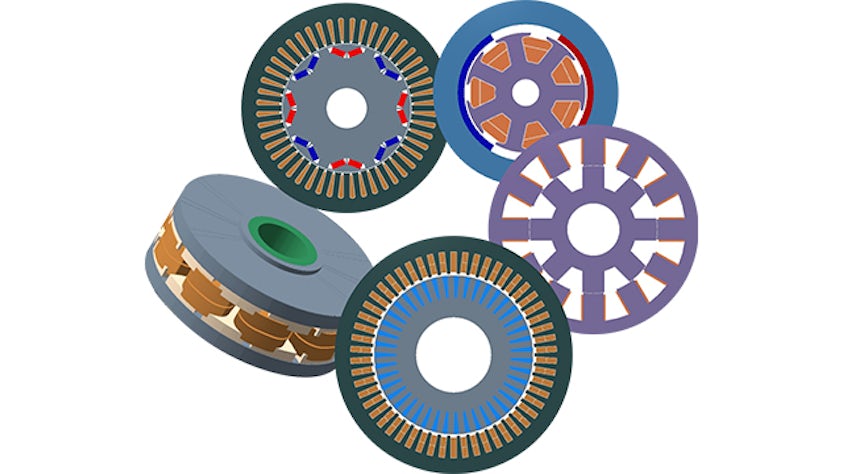

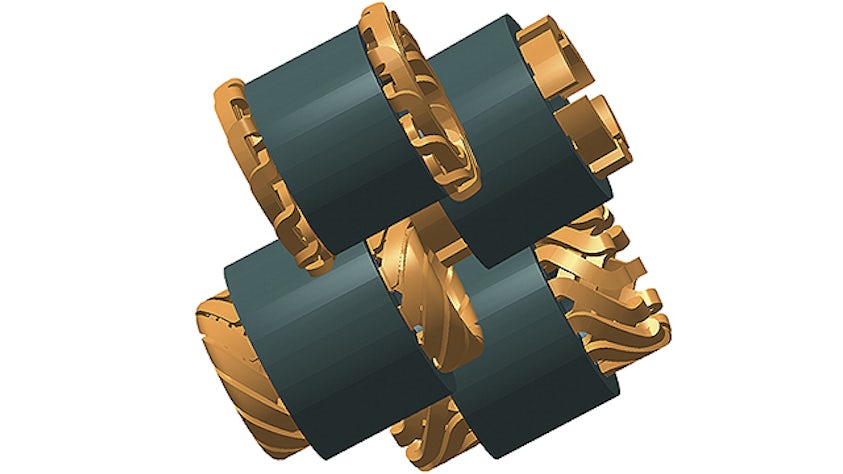

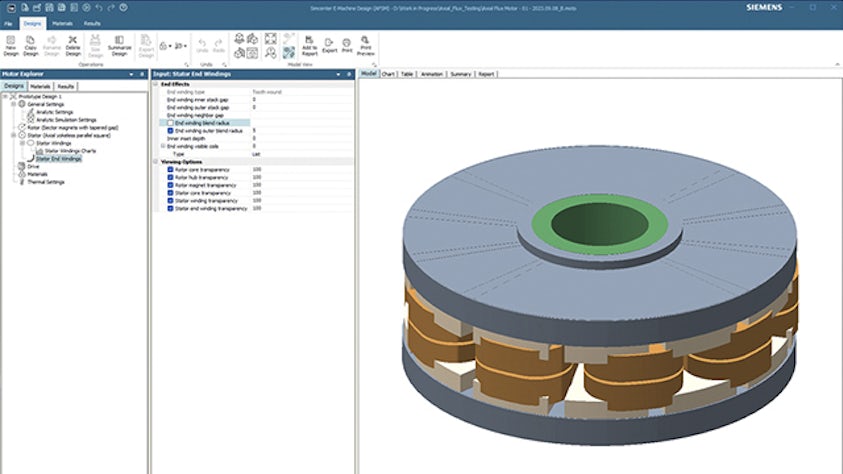

这是市面上为数不多的一款同时为径向和轴向磁通电机提供参数化模板和建模功能的机械设计工具。

此外,E-Machine Design 还可通过专门指定的门户与 Simcenter HEEDS 产品无缝连接,以进行优化或设计探索。

使用 Simcenter Xcelerator 保持集成性

要生产出既高效又安静的高端电动汽车,需要一个工程师团队研究电机及其外壳、变速器等零部件,以了解车辆的整体 NVH 性能。Simcenter 工具可仿真所有这些功能,且其原生文件格式使所有工程师都可以使用设计更新,确保每个人都在处理最新文件。

加速、创新和优化您的电机设计流程

Simcenter E-Machine Design 是一款站在巨人肩膀上的新产品,可充分利用 Simcenter SPEED、Simcenter Motorsolve 和 Simcenter MAGNET 复制电机实验。