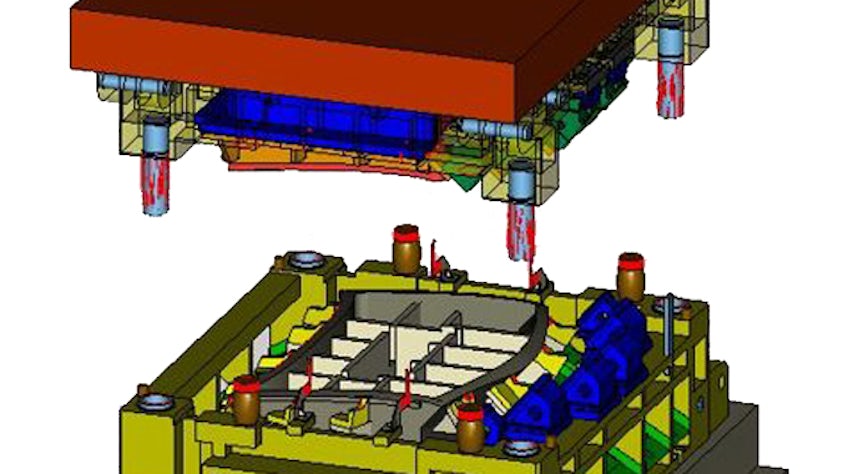

Diseño de troqueles totalmente validados

Define la cinemática durante el diseño de troqueles. Captúrala en una biblioteca de herramientas de matriz para reutilizarla, incluidos los valores de traslación, rotación, límites y tope, así como las levas lineales, giratorias, corredera de llenado, corredera de manivela y arrastre de enlace.

Calcula las colisiones dentro del troquel en cuanto a ubicación y profundidad de penetración. Genera informes detallados para el análisis de los detalles de las colisiones con el fin de mejorar y validar el diseño general de troqueles.