NX X Manufacturing Standard incorpora programación automatizada de piezas prismáticas mediante diseño asistido por ordenador (CAD), así como y fabricación asistida por ordenador (CAM), con funcionalidades de fresado de 2,5 ejes, perforación, torneado y palpado en la máquina. Con una integración impecable en herramientas CAD de primer nivel, optimiza la programación de piezas prismáticas y reduce el tiempo de programación hasta un 90 %.

Funciones clave

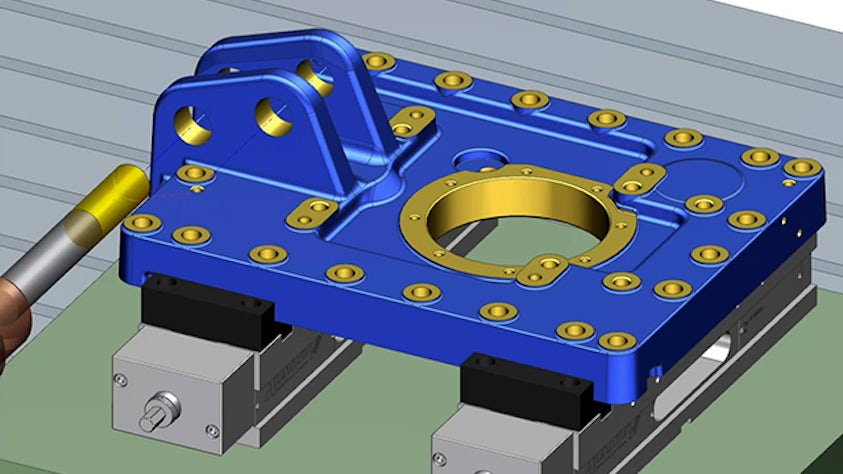

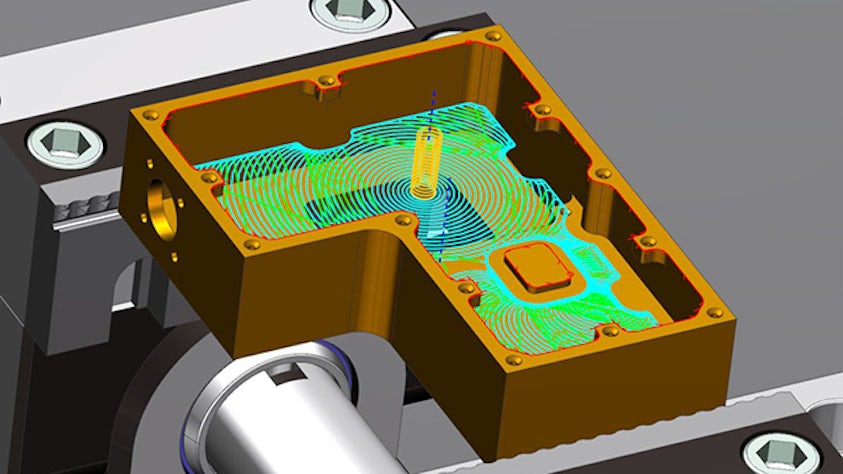

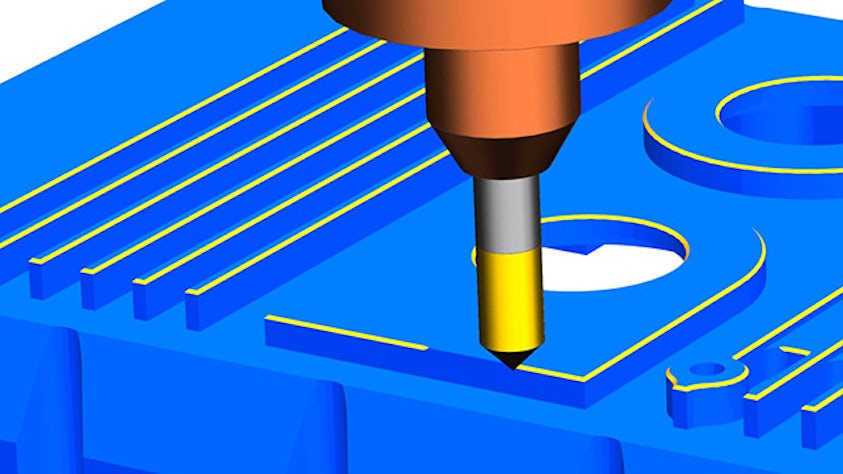

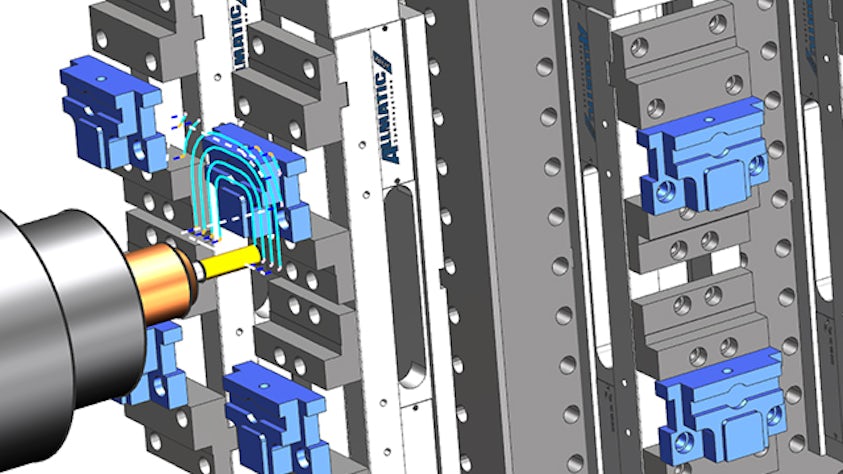

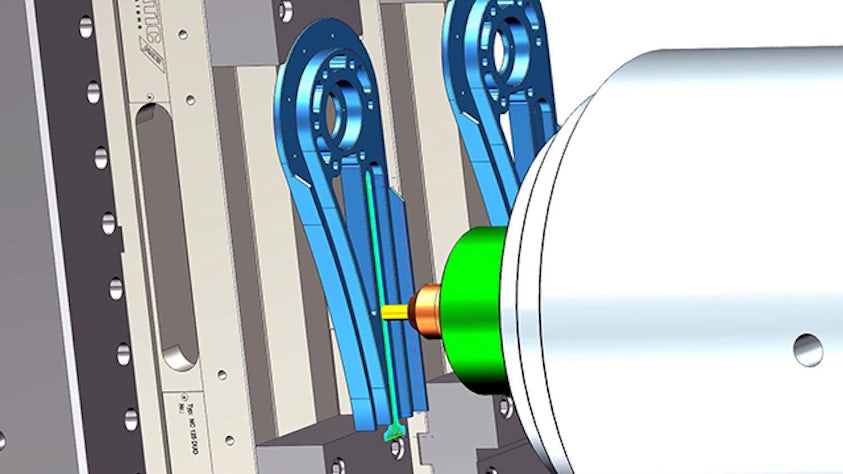

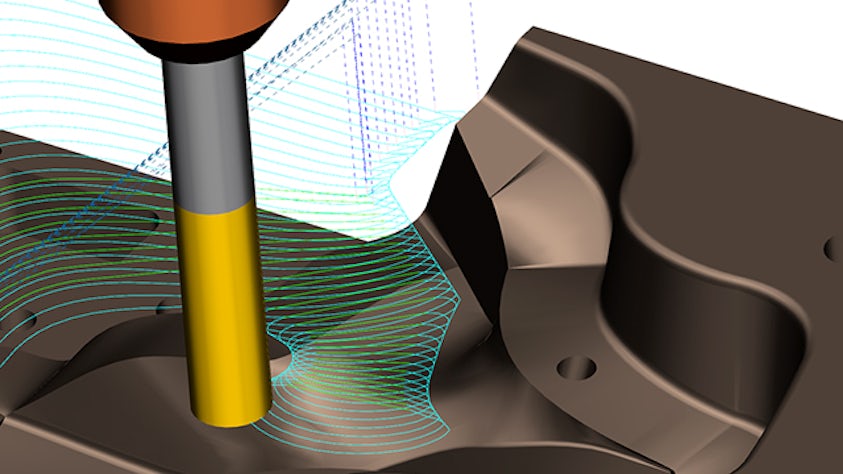

Fresado de 2,5 ejes: mecaniza con fresado basado en volumen para posibilitar una programación más rápida de las piezas prismáticas y el mecanizado basado en figuras automatiza la programación. Las estrategias de mecanizado de alta velocidad pueden reducir el tiempo de mecanizado hasta en un 60 %. Asimismo, la programación de varias piezas aumenta la productividad.

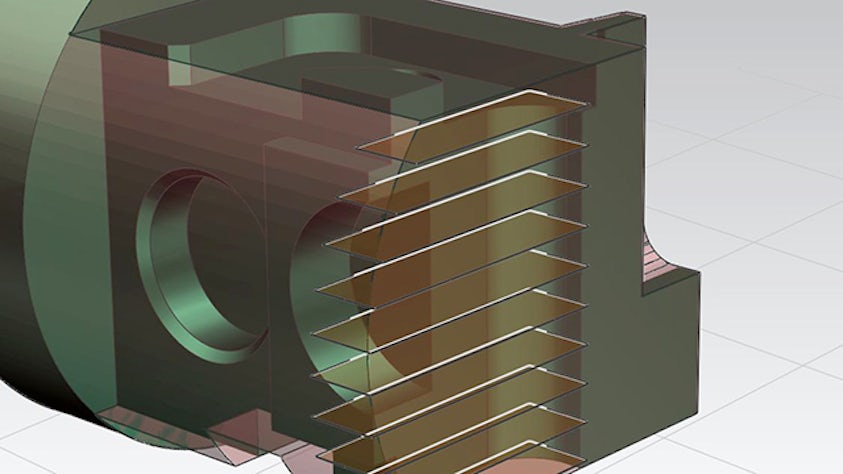

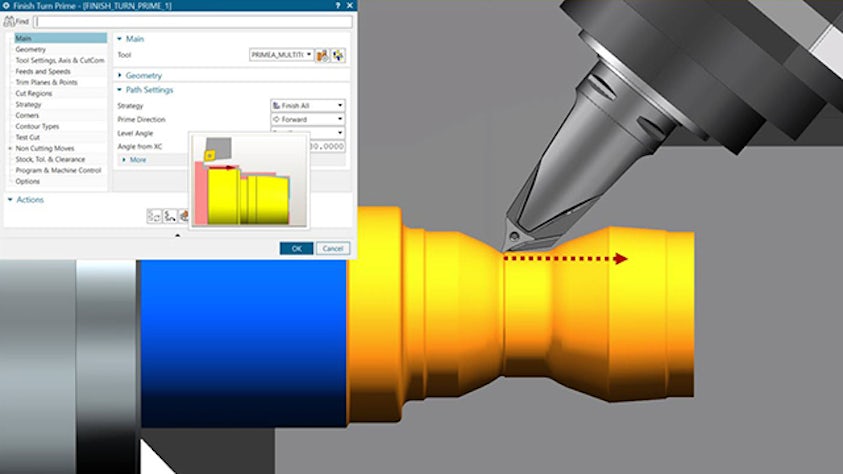

Torneado: mecaniza con eficiencia piezas cilíndricas en máquinas de torno con husillos únicos y dobles mediante funcionalidades integrales de torneado. Las estrategias de desbaste incluyen operaciones de cara, torneado, torneado inverso, mandrinado y corte sesgado; por su parte, las técnicas de acabado abarcan estrategias de pasadas múltiples y refrentado. La perforación de agujeros incluye operaciones de punto, taladrado, punteado, viruta, escariado y roscado, con ranurado que ofrece un control flexible del punto de seguimiento y roscado para diámetros exteriores e interiores.

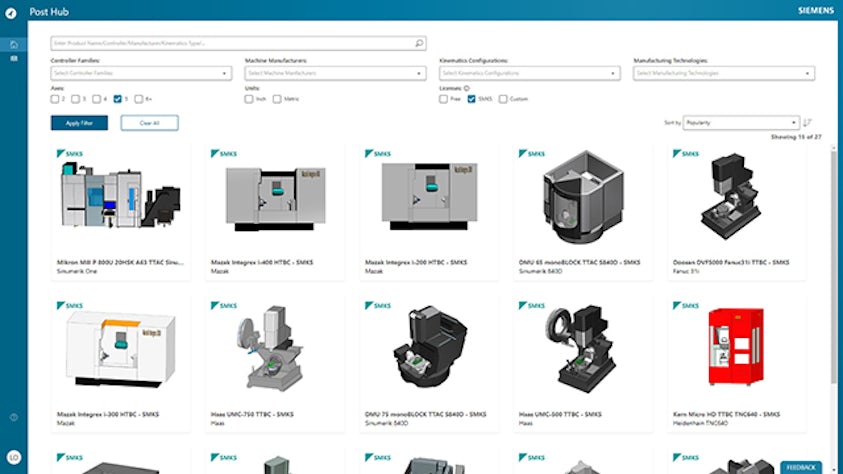

Simulación, posprocesamiento y documentación de la planta de producción: utiliza una animación de la trayectoria de herramientas y un posprocesador para generar código G listo para producción. Post Hub, una biblioteca basada en la nube con más de 1000 posprocesadores, y el configurador de posprocesamiento permiten modificar o crear nuevos posprocesadores. Machine Tool Builder y las herramientas de instrucciones de trabajo crean modelos cinemáticos y desarrollan instrucciones de trabajo asociativas.

Herramientas CAD integradas: NX CAM proporciona funcionalidades de CAD líderes en la industria para el modelado, la edición y el ensamble, que aceleran la programación de control numérico por ordenador (CNC). Con los traductores integrados, puedes leer todos los formatos de datos estándar, como IGES, DXF, STEP, STL y JT.

Las métricas de fabricación se basan en pruebas internas de mecanizado o en estudios comparativos internos.

Ventajas de NX X Manufacturing:

- Programa mediante avanzadas herramientas CAD/CAM adaptadas a tus necesidades de fabricación

- Reduce los costes iniciales y optimiza la implementación con tecnología en la nube

- Aumenta la productividad con funcionalidades de programación CNC líderes de la industria

- Mejora la colaboración entre las partes interesadas mediante soluciones basadas en la nube

- Amplía la funcionalidad de tus soluciones con Value Based Licensing

Solución personalizable

Amplía la funcionalidad NX X Manufacturing Value Based Licensing para configurar y personalizar tus soluciones, entre las que se incluyen:

- Avanzadas herramientas de modelado

- Funcionalidades de mecanizado especializadas

- Simulación mediante código G

- Solución moderna de posprocesamiento