先進のオンマシン・プローブで部品の製造効率を向上

NX CAMオンマシン・プローブで検査パスを生成してプロセスのばらつきを検出し、加工パラメーターを調整して一貫した部品品質を実現します。

機械でリアルタイムに測定データを取得できるため、プロセスを安定させ、やり直しを減らし、仕様を満たした正確な部品を毎回製造できます。

NX CAMオンマシン・プローブで検査パスを生成してプロセスのばらつきを検出し、加工パラメーターを調整して一貫した部品品質を実現します。

機械でリアルタイムに測定データを取得できるため、プロセスを安定させ、やり直しを減らし、仕様を満たした正確な部品を毎回製造できます。

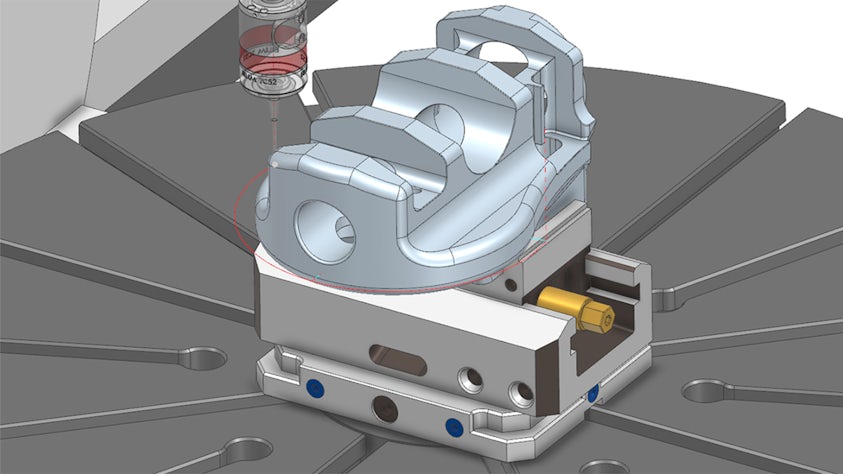

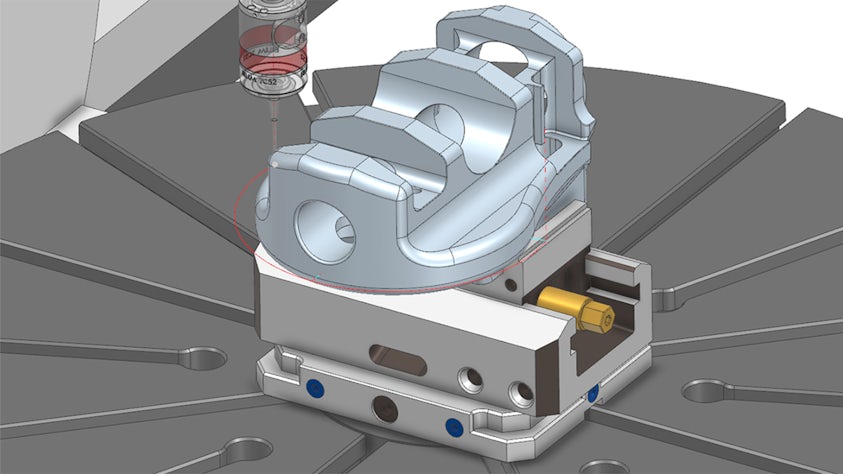

オンマシン・プローブにより、加工前、加工中、加工後の正確なリアルタイム検査が可能になり、ダウンタイムの短縮と廃棄の防止につながります。主要なプロセスを自動化し、人間の介入を最小限に抑えることで、スループットを向上させ、「完全自動化」加工の範囲を広げて高品質の結果を保証します。

このインテリジェントなプロービング・ソリューションは、生産性を最大化し、変化する顧客ニーズに迅速に対応するのに役立ちます。

加工前検証を実施して、部品が正しく配置され、取付具で固定され、材料の状態が仕様を満たしていることを確認することで、安心して各加工オペレーションを開始できます。

必要に応じて加工プロセス、機械の位置合わせ、またはプログラムを調整して、エラーを最小限に抑え、スムーズにオペレーションを成功させます。

スピンドル・プローブを使用すると機械上で直接作業オフセットまたはゼロ点をすばやく調整し、決定できるため、セットアップ・プロセスを簡素化します。

プローブを使用して部品の位置を検証し、エラーをチェックすることで、複雑な治具は不要になるため、正確な加工を保証し、精度と効率を向上させます。

オンマシン・オフセット更新でツールの精度を維持し、摩耗や形状の変化に合わせてツールデータを自動調整します。

オフマシン (機械から取り外して行う) 測定の必要性をなくすことで、ダウンタイムを削減し、一貫した精度と高品質の出力を確保します。

フィーチャ測定機能で部品の品質を監視し、機械上で直接フィーチャの寸法を測定して解析します。

ワークピースを取り外さずに品質を検証し、適応型プロセス制御によってばらつきを減らし、やり直しを最小限に抑えながら要件仕様を満たせるようにします。

摩耗や形状変更が生じた場合でも、スピンドル・プローブを使用して、機械で直接ツールの長さや半径を測定して修正することで、ツール管理を最適化します。

ダウンタイムを回避し、精度を維持して、一貫した高品質の結果を実現します。

CMM検査プログラミング、製造現場の実行、データ解析を連携させることで、データ主導のプロセスで品質管理を自動化します。

検査パスを生成してシミュレーションし、製品製造情報 (PMI) を使用してプログラムし、加工部品が3D設計に一致しているかどうかを監視します。クローズドループ・プロセスによって、継続的な改善を推進します。

特定の部品製造ニーズに対応するシーメンスの幅広いクラウド・ソリューションの詳細をご覧ください。