単一の包括的なCAM (コンピューター支援製造) ソフトウェアを使用すると、部品製造プロセス全体を変革できます。

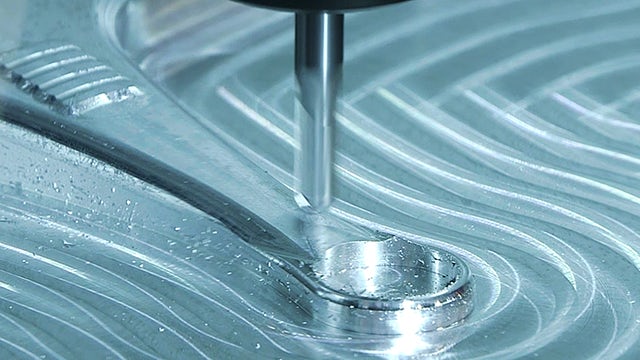

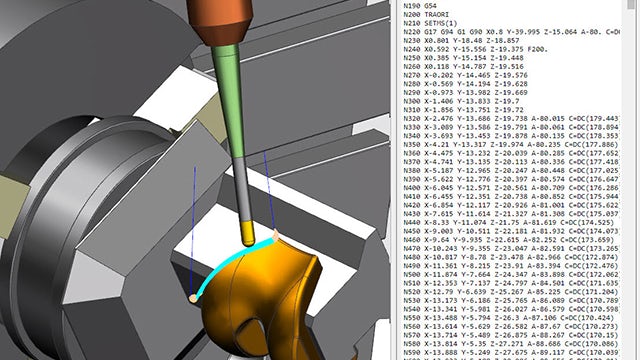

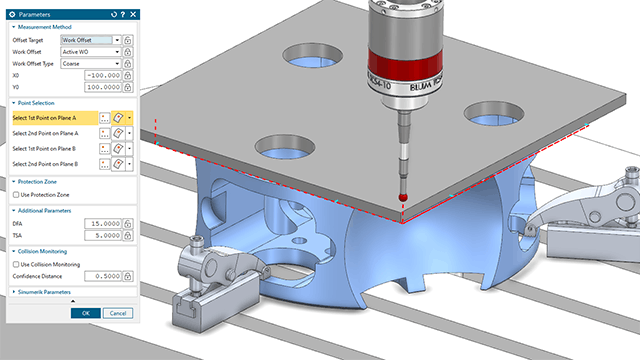

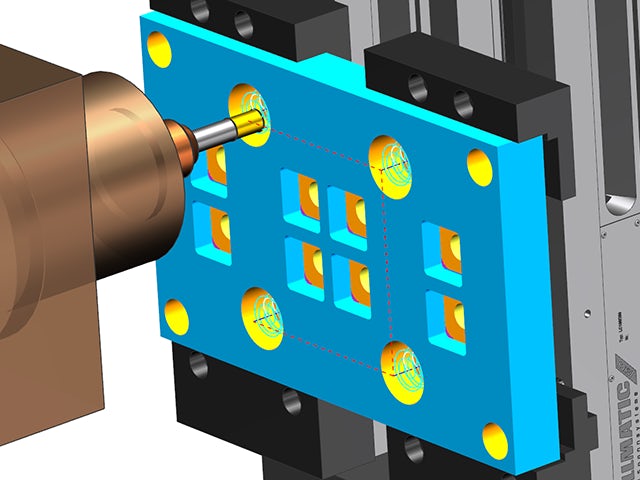

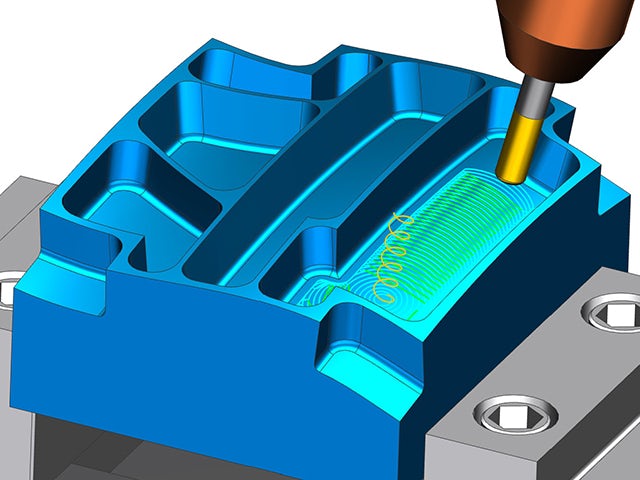

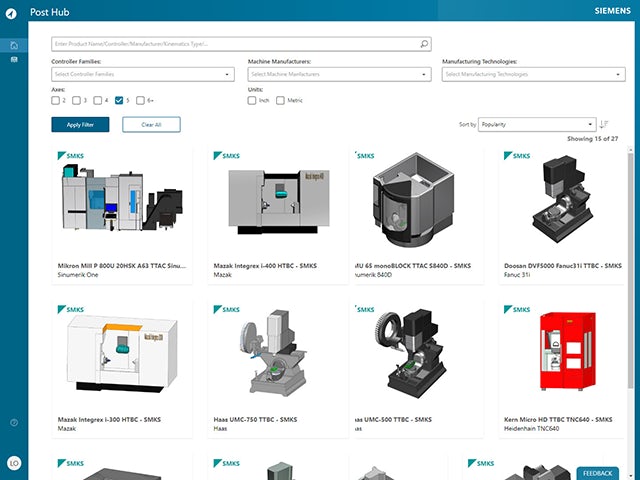

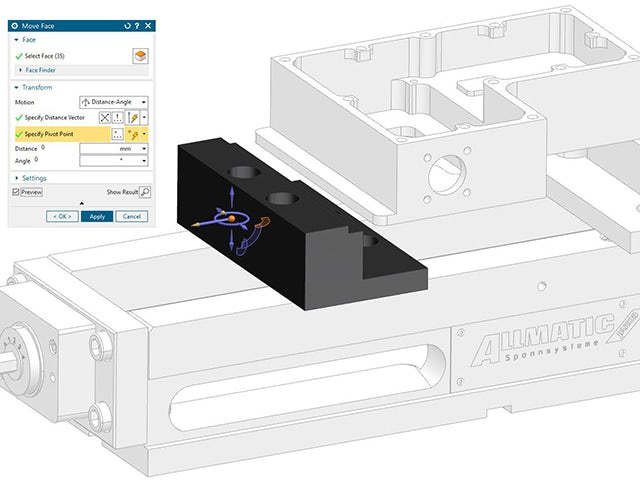

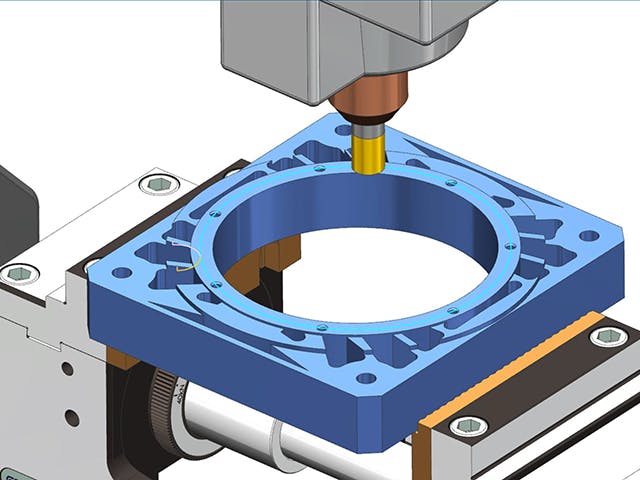

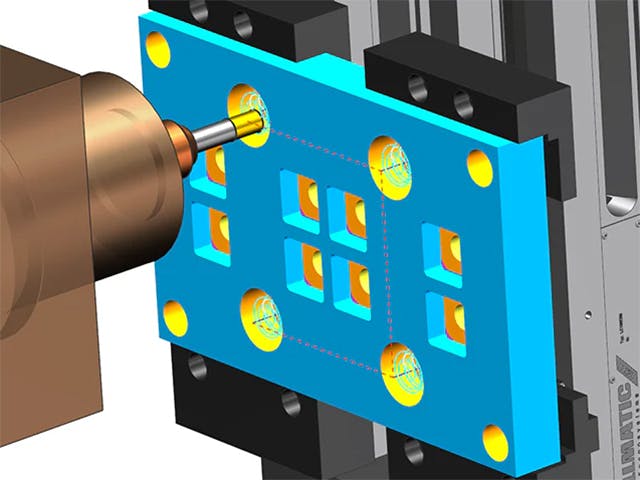

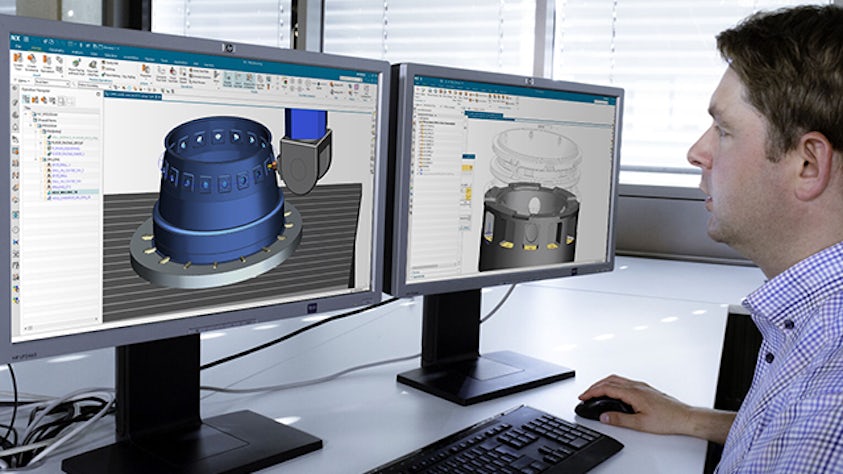

NX CAMソフトウェアは、高度なツールパス技術と統合型Gコード駆動シミュレーションを通して、NCプログラミングの自動化、機械加工の高速化、高精度部品の製造を支援します。

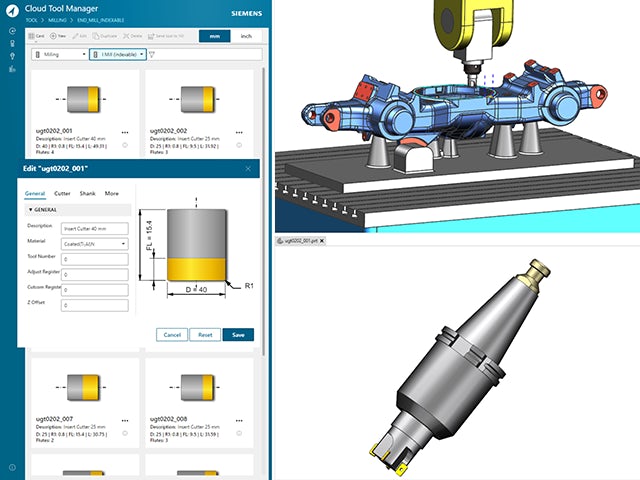

NX X Manufacturingは、業界をリードするコンピューター支援設計および製造 (CAD/CAM) 機能と、柔軟性、セキュリティ、拡張性を備えたクラウド技術を統合した次世代のSaaS (Software-as-a-Service) ソリューションです。このソリューションを使用すると、チームの効率性が強化されます。

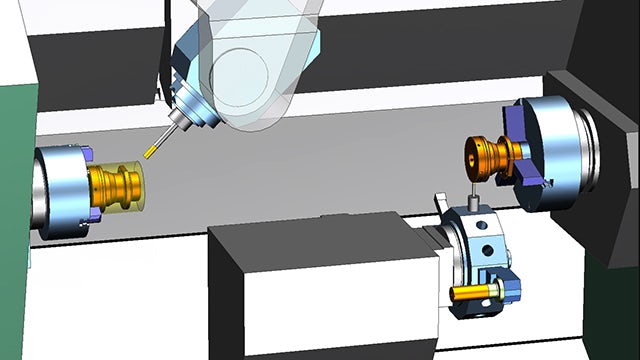

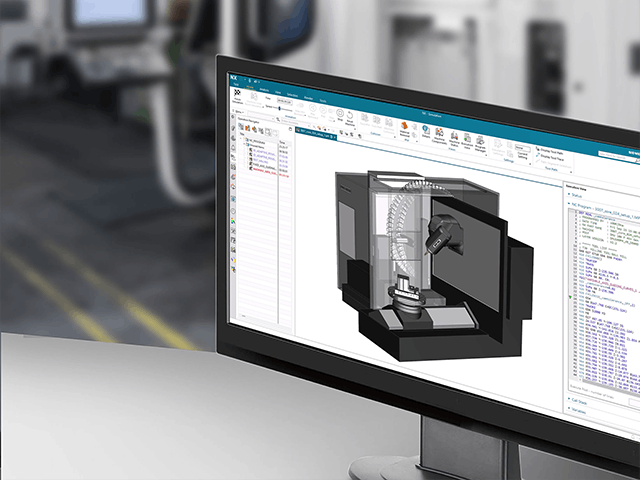

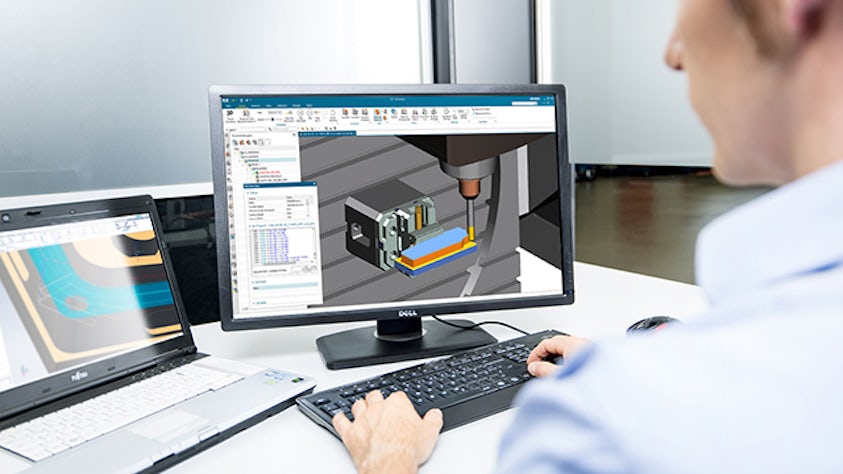

NX CAMをシーメンスの幅広いデジタル・マニュファクチャリング・ソリューションにシームレスに統合することで、一歩先を行くことができます。3Dプリント、ロボティクス、生産ライン設計などに対応するさまざまなソフトウェアで、進化する業界のニーズに対処できます。