NX X Manufacturing AdvancedはStandard製品に、高度な3軸および2.5軸ミル加工、旋削、オンマシン・プローブ機能を始めとする機能を取り入れた製品です。業界をリードする統合型CAD/CAMツールが、金型やダイなど、最も困難な自由形状部品の準備とプログラミングを効率化します。強力なツールパス技術によって、部品の表面を高品質に仕上げる一方で、切削時間を最大60%削減できます。

主な特長

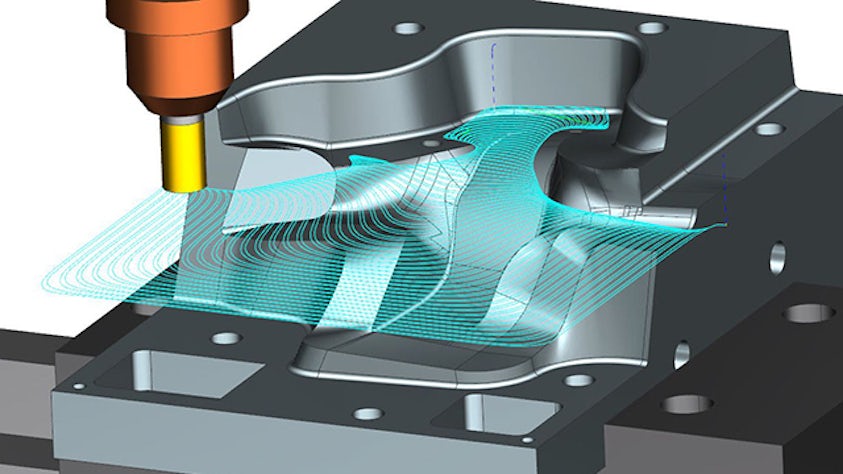

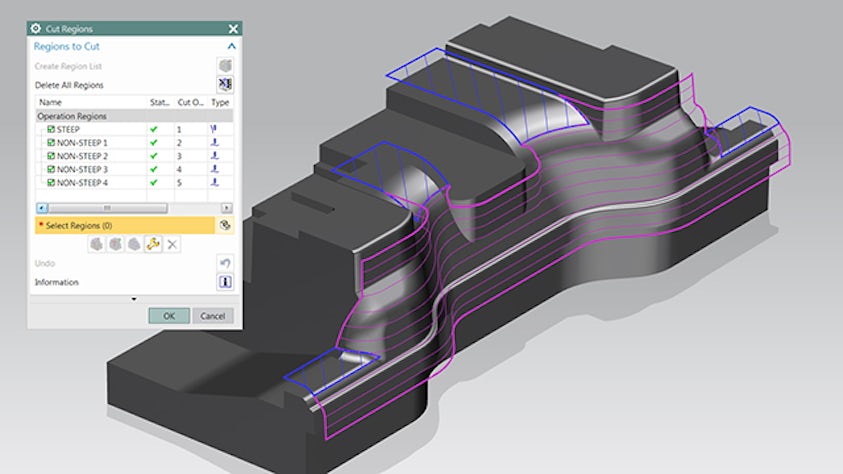

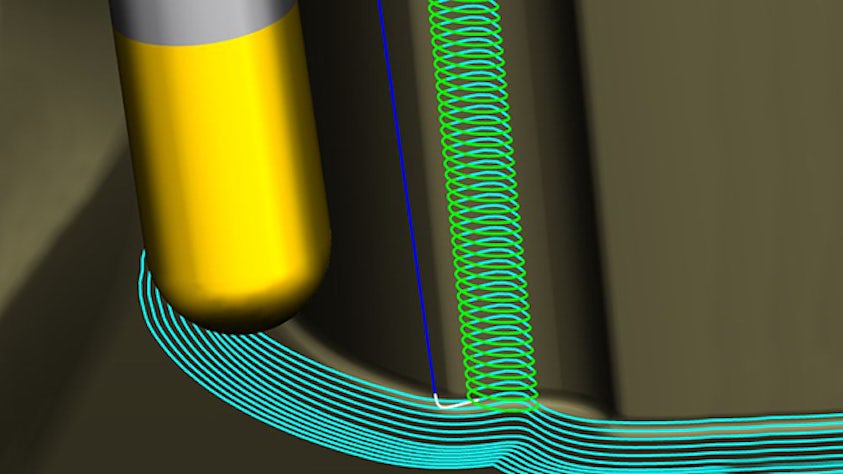

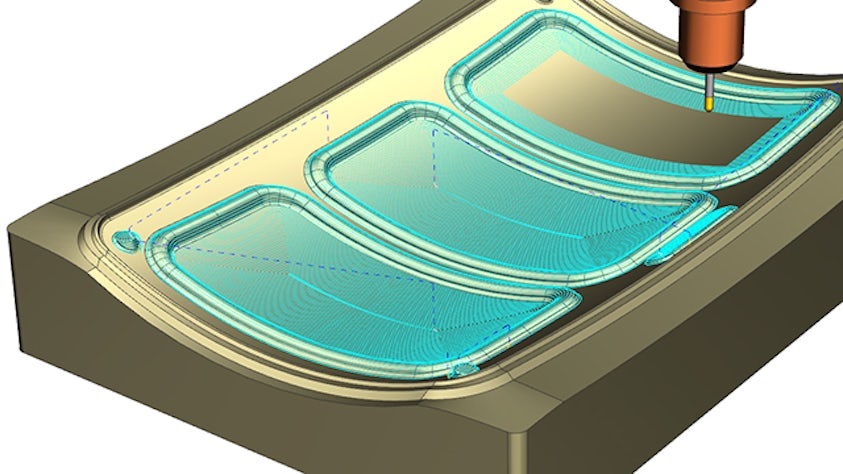

3軸ミル加工: 一連の高度な数値制御 (NC) プログラミング・ツールを使用して、フリーフォーム・フィーチャを持つ高品質部品を製造します。3Dアダプティブ荒削りによって、加工時間を半分に短縮できます。自動レストミリング (削り残し部加工) は多段階荒加工に対応し、スループットを向上させます。切削領域管理法は、機械加工技法の精密な制御が可能です。部品形状の自然な形に沿った滑らかな仕上げ技法により、高品質の表面仕上げを実現します。

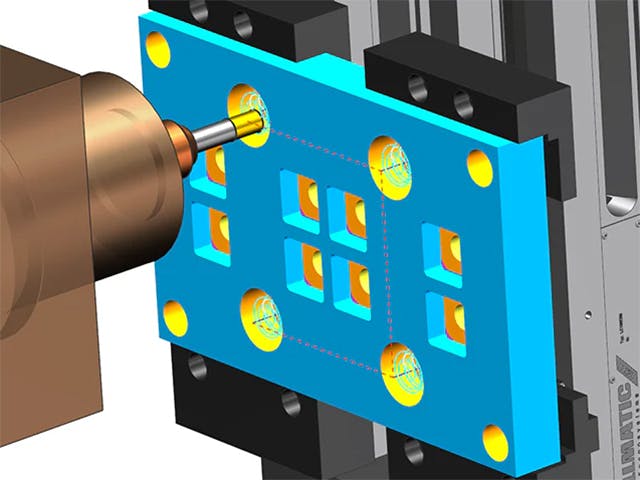

2.5軸ミル加工: ボリューム・ベースのミル加工で角柱部品のプログラミング時間を短縮し、フィーチャベース加工でプログラミングを自動化します。高速加工方式によって加工時間を最大60%短縮でき、複数部品プログラミングによって生産性が向上します。

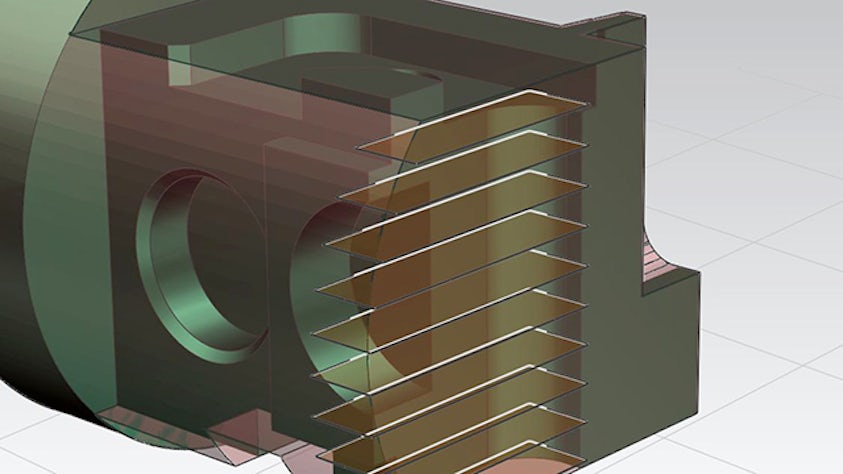

旋削: 1スピンドルと2スピンドルを備えた旋盤で、包括的な旋削機能を使用して円筒部品を効果的に加工します。荒加工技法には、面加工、旋削、背面旋削、ボア、アンダーカットが含まれます。仕上げ技法には、マルチパス方式や面加工が含まれます。穴あけ加工には、スポット、ドリル、ペック、チップ、リーマ、タップなどがあり、グルービングは柔軟なトラック・ポイント制御が可能で、外径と内径のねじ切りを行えます。

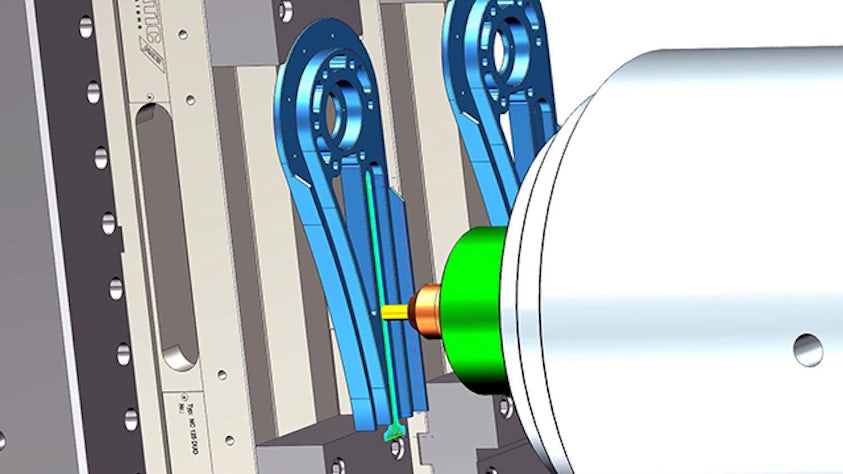

オンマシン・プローブ: プローブパスを生成し、ビジュアル化します。ミル加工と旋削のオンマシン・プローブ・サイクルを作成します。出力されたNCコードを統合されたポストプロセッサーで使用します。部品、プローブ、および工作機械のデジタルツインを使用して、プロセスをシミュレーションします。プロセスばらつきを検出し、機械加工パラメーターを調整します。

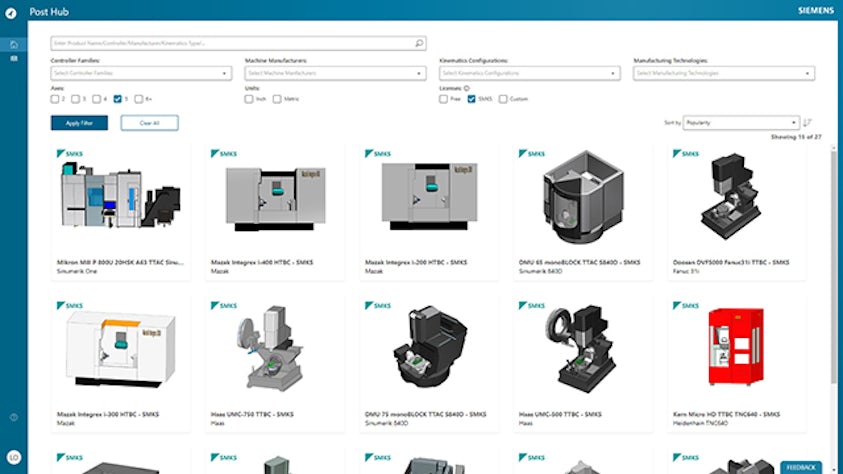

シミュレーション、ポスト処理、およびショップ・ドキュメント: ツールパスのアニメーションとポストプロセッサーを使用して、すぐに製造に使用できるGコードを生成します。1,000を超えるポストプロセッサーを収集した、クラウドベースのライブラリであるPost Hubと、Post Configuratorを使用すると、新しいポストプロセッサーを修正または作成できます。工作機械構築ツールと作業指示書ツールは、キネマティクス・モデルを構築し、関連する作業指示書を作成します。

統合型CADツール: NX CAMは、モデリング、編集、アセンブリのための業界をリードするCAD機能を提供し、CNCプログラミングを高速化します。統合された変換ツールを使用すると、IGES、DXF、STEP、STL、JTを含むすべての標準的なデータ・フォーマットを読み取ることができます。

製造指標は、社内の試験加工または社内の比較スタディに基づいています。

NX X Manufacturingのメリット:

- お客様の製造ニーズに合わせて、高度なCAD/CAMツールを活用したプログラミング

- 初期費用を削減し、クラウド・テクノロジーで導入を合理化

- 業界をリードするCNCプログラミング機能によって、生産性を向上

- クラウド対応ソリューションを使用して、関係者間のコラボレーションを強化

- トークン・ライセンスにより、ソリューションの機能を拡張

カスタマイズ可能なソリューション

NX X Manufacturingのトークン・ライセンスで機能を拡張し、以下のようなソリューションを構成、カスタマイズできます。

- 高度なモデリング・ツール

- 特殊な加工機能

- Gコード駆動シミュレーション

- 最新のポスト処理ソリューション