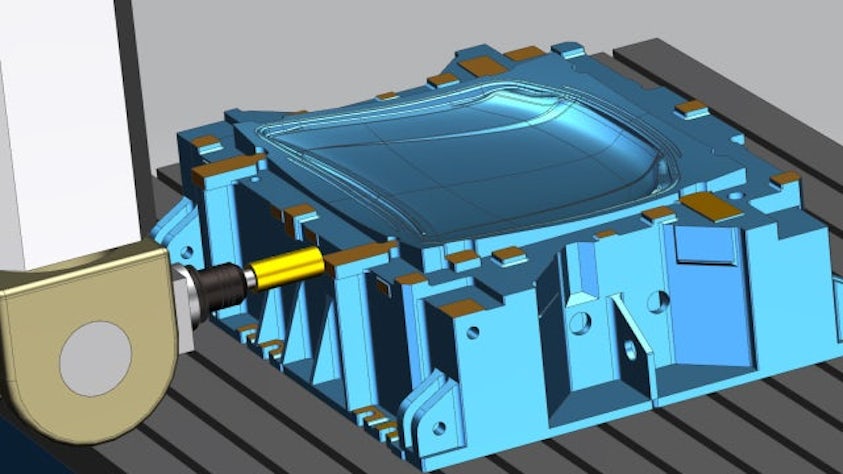

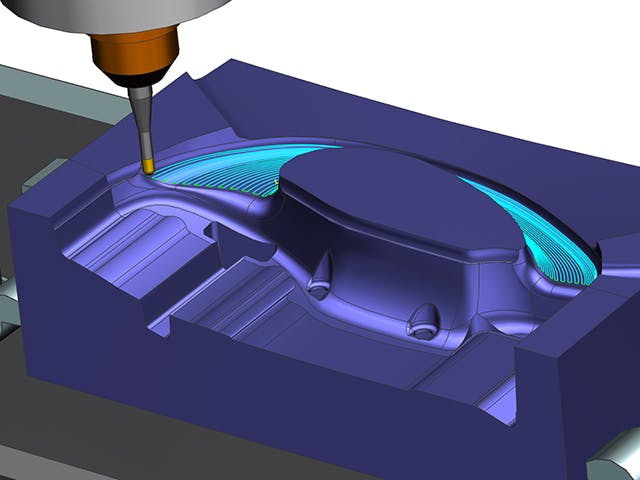

Manufacture mold inserts with excellent finish

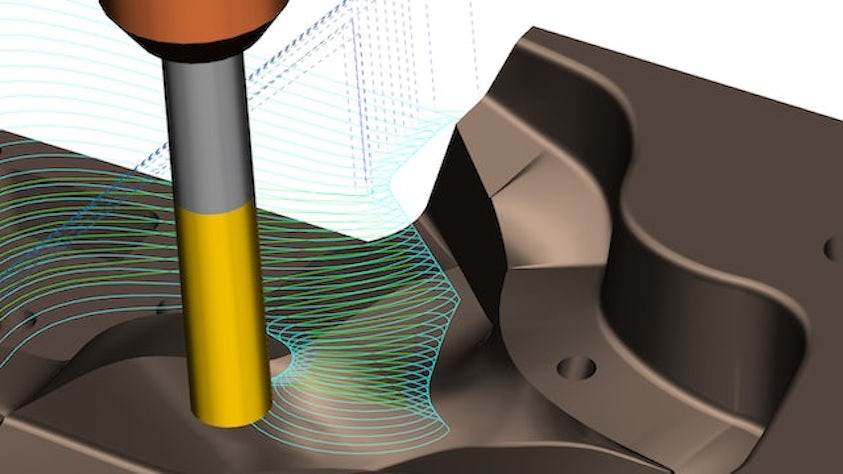

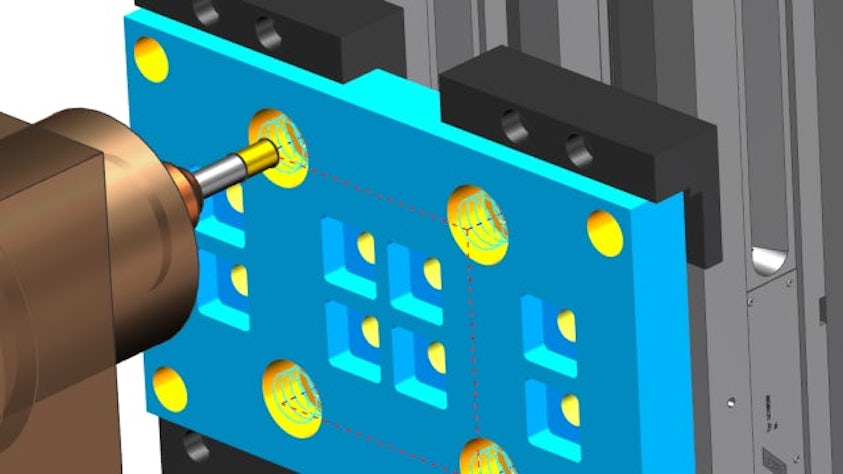

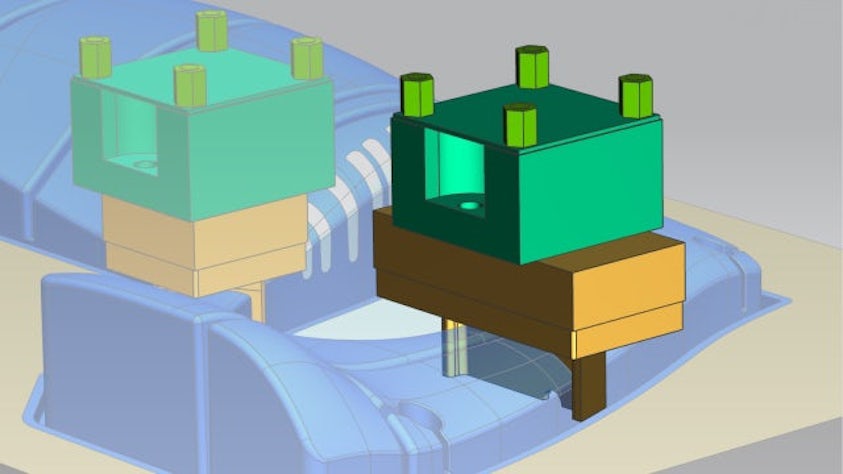

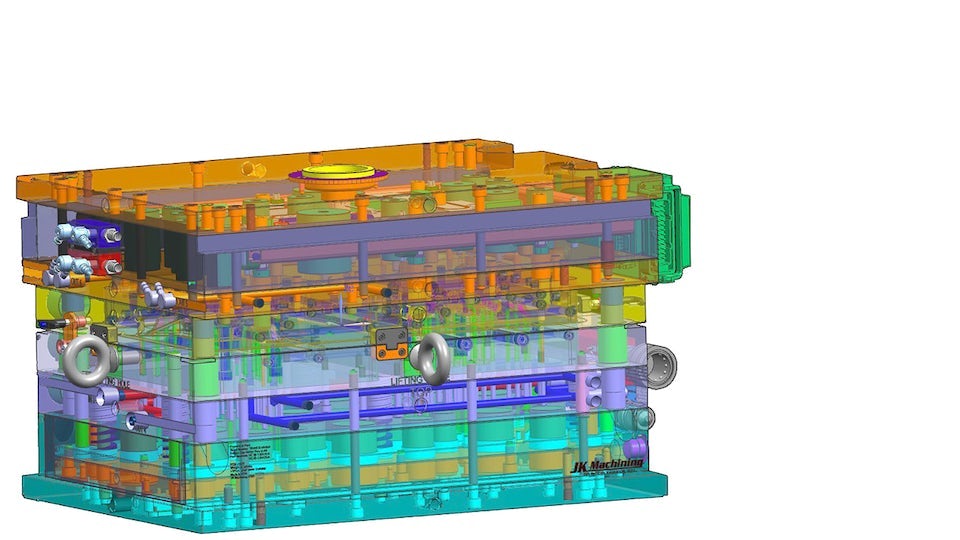

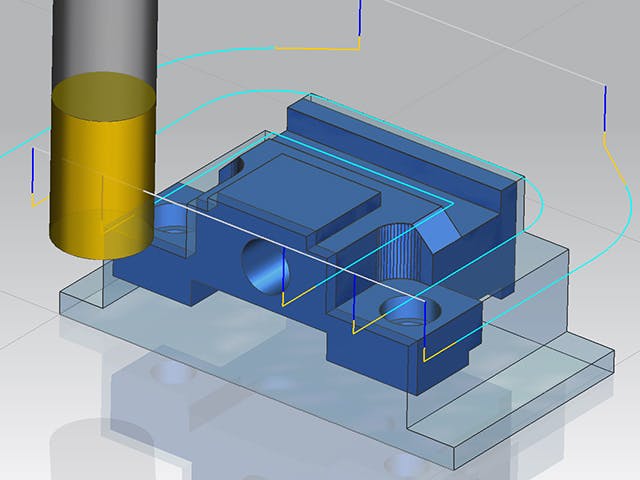

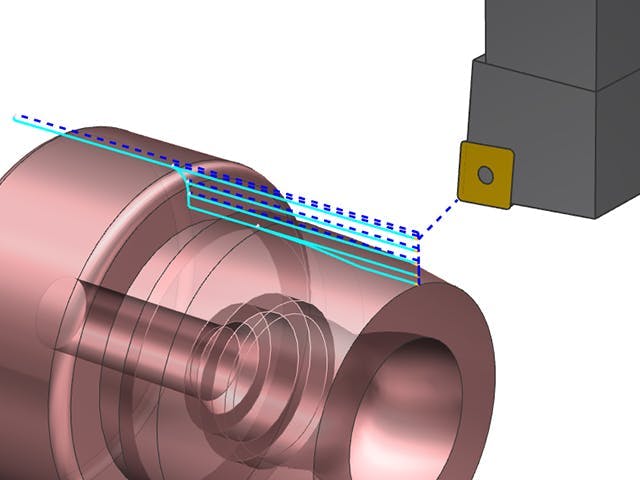

Manufacture high-quality mold inserts using a complete set of advanced NC programming tools. Next-generation, high-speed mold machining techniques reduce cycle time, extend tool life and reduce production costs.

Advanced 3+2 milling and 5-axis machining methods allow you to produce challenging molds with deep cavities, while also improving surface finish and reducing machining time.