Streamline programming of prismatic parts created in any CAD system using advanced capabilities for 2.5-axis milling.

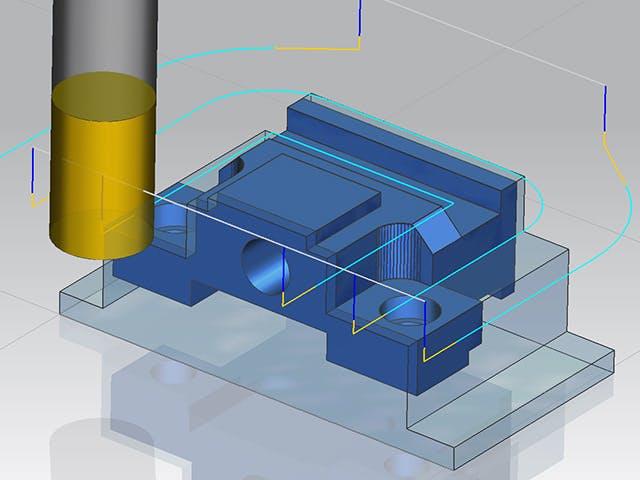

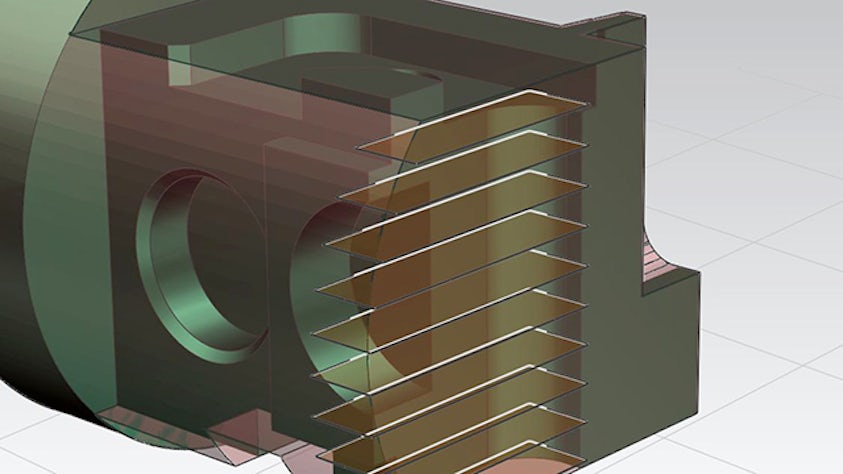

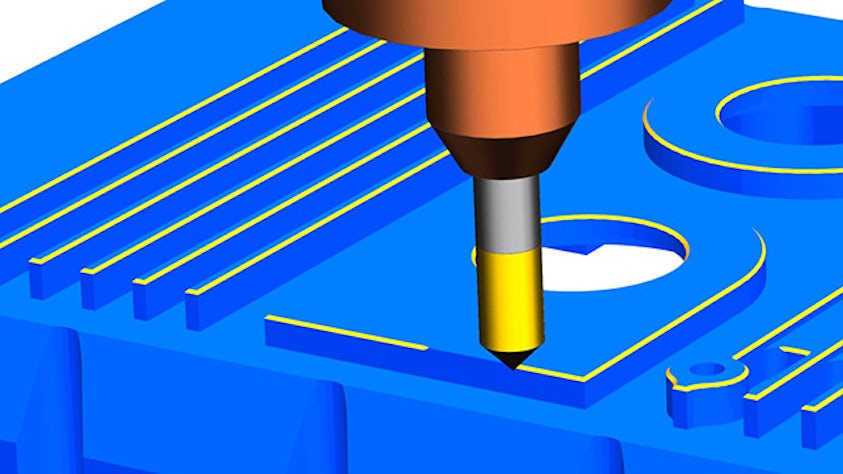

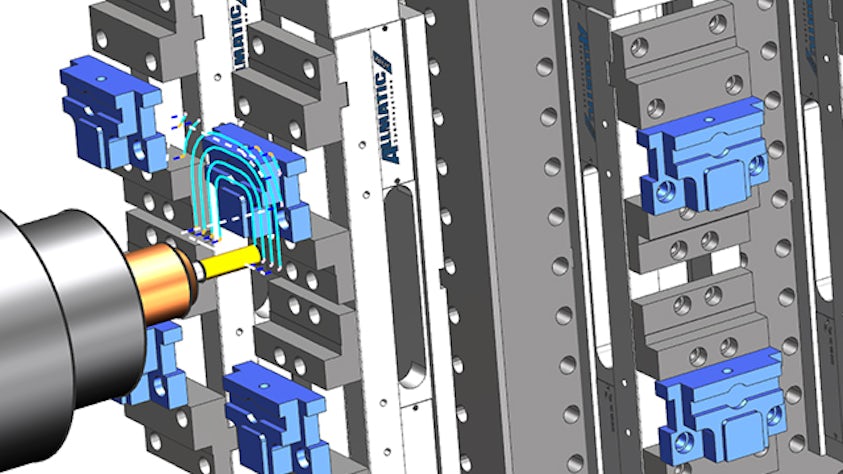

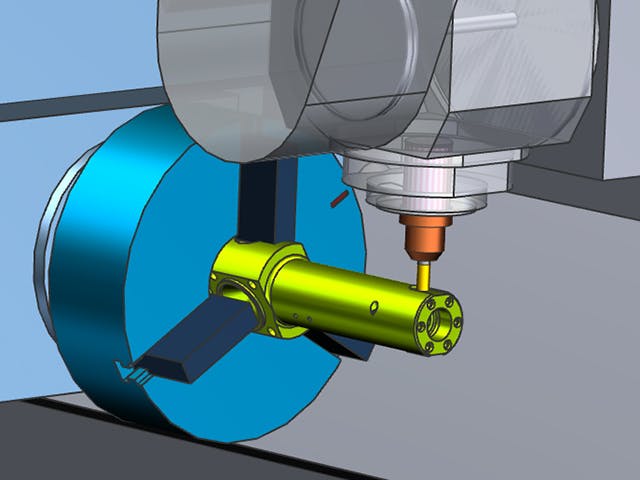

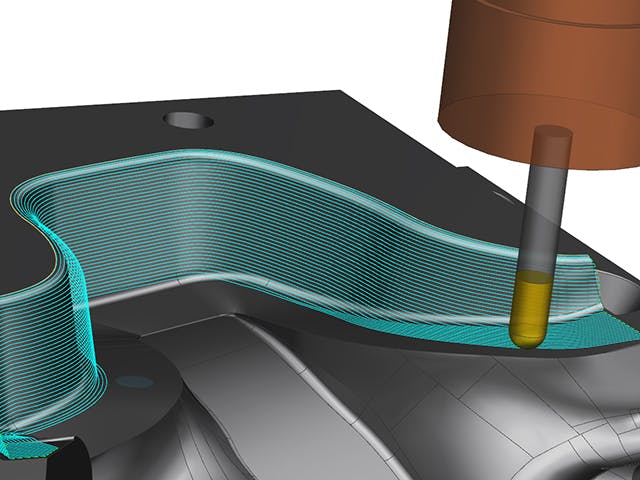

Program advanced toolpaths

Rapidly create highly efficient toolpaths with modern programming techniques, such as feature-based machining, volume-based milling and multiple-part programming. Easily define safe and optimized machining operations by programming in the context of the complete setup, including the workpiece, fixtures and the other machine components.

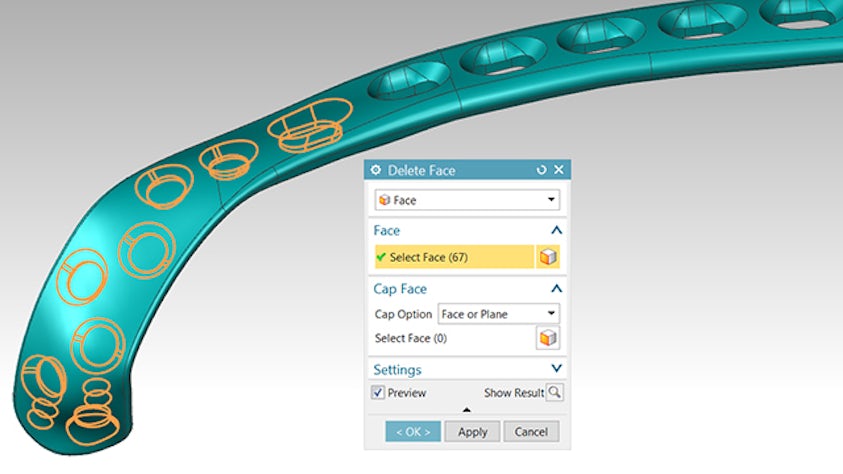

Use integrated CAD tools

Open all standard CAD files with comprehensive translators. Prepare the imported 3D models for NC programming using integrated design tools like synchronous technology. Model complete machine setups with assembly capabilities, enabling you to create an accurate digital replica of your setup.

Output validated programs

Generate validated, production-ready NC programs using the cloud-based postprocessing solution and integrated machining simulation capabilities. Digitally connect planning and production with associative shop documentation, including tool lists and setup sheets.

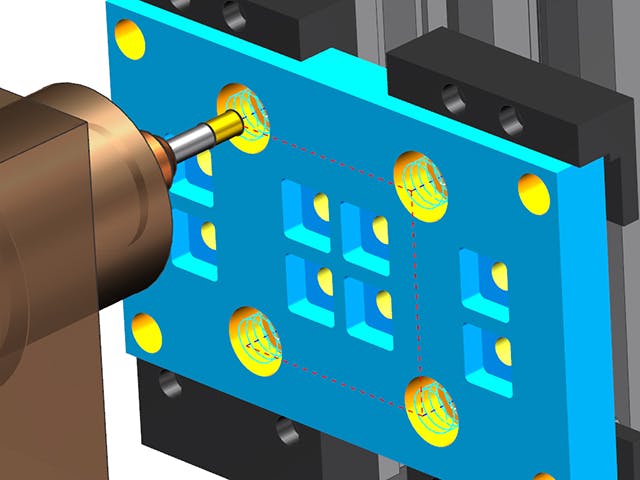

NX CAM provides advanced programming capabilities for 2.5-axis milling, including:

- Feature-based machining

- Volume-based milling

- High-speed machining

- Automated deburring

- Hole-making operations

- Multiple part machining

- Multi-stage machining

- Z-level finishing

- 3+2 positioning

- In-Process Workpiece (IPW)

- Feed rate optimization

- Machining simulation

- Postprocessing

- Probing cycles

Included integrated CAD tools:

- Synchronous technology

- Assemblies

- CAD translators