Transform your entire part manufacturing process by using a single, comprehensive computer-aided manufacturing, CAM software.

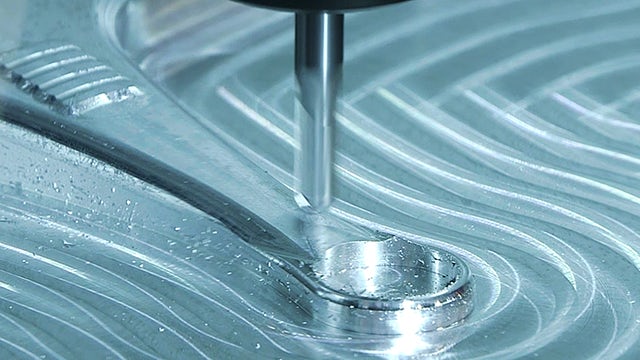

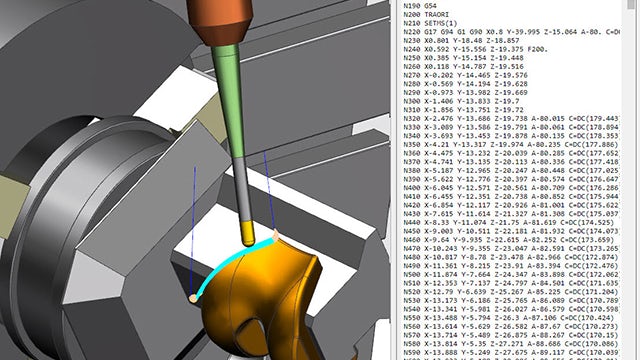

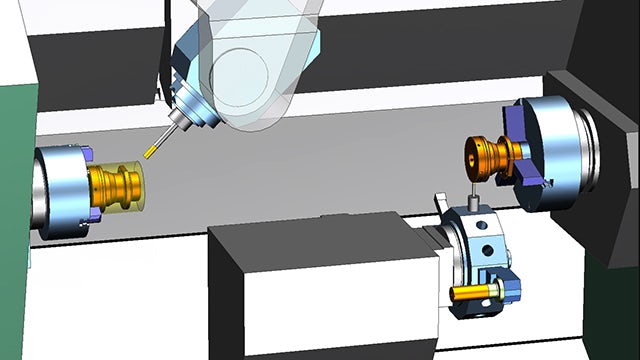

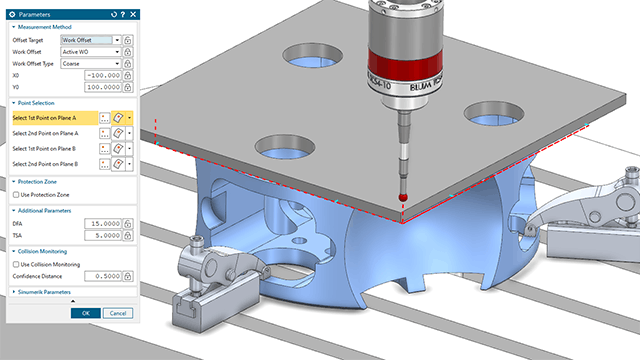

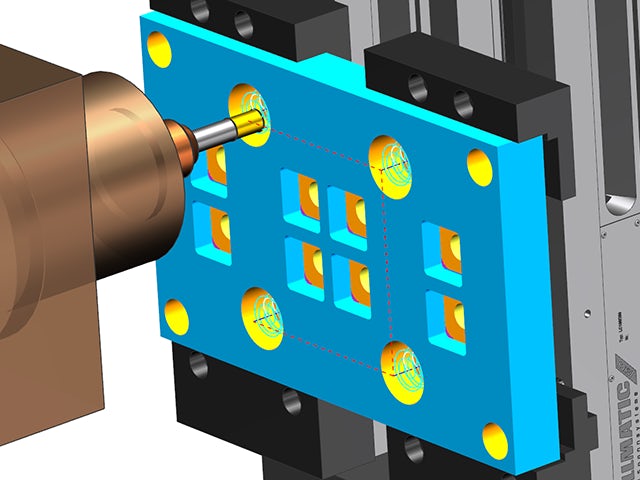

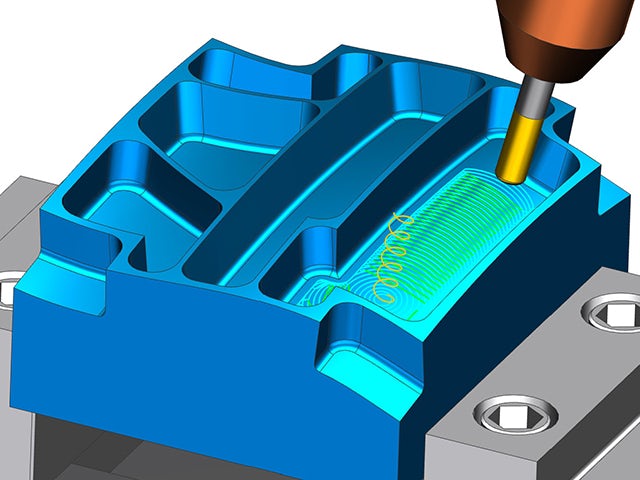

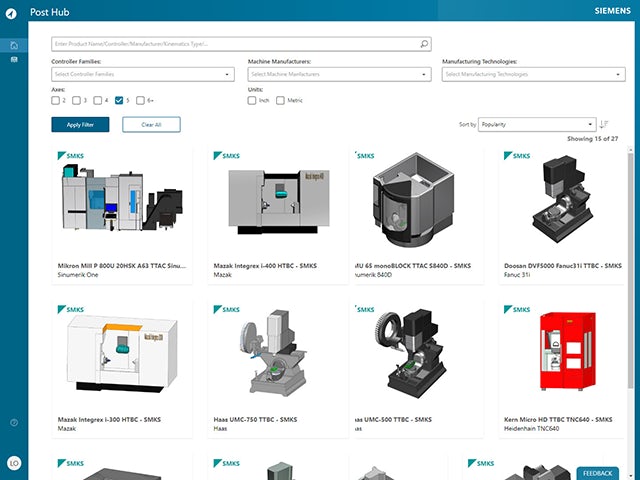

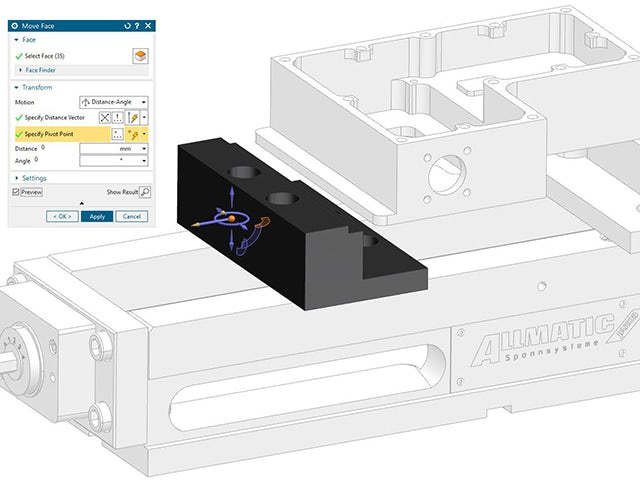

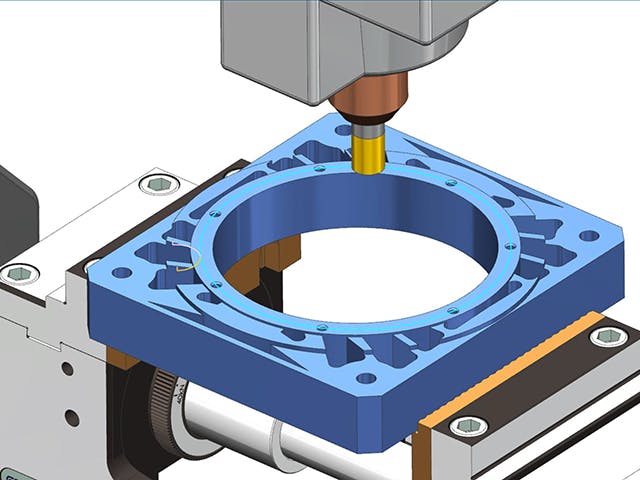

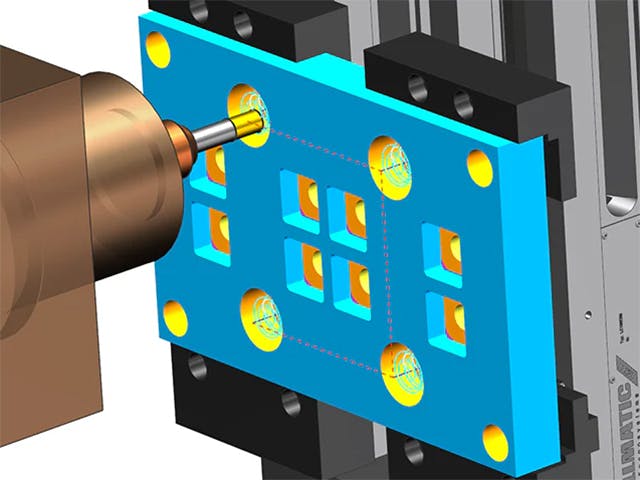

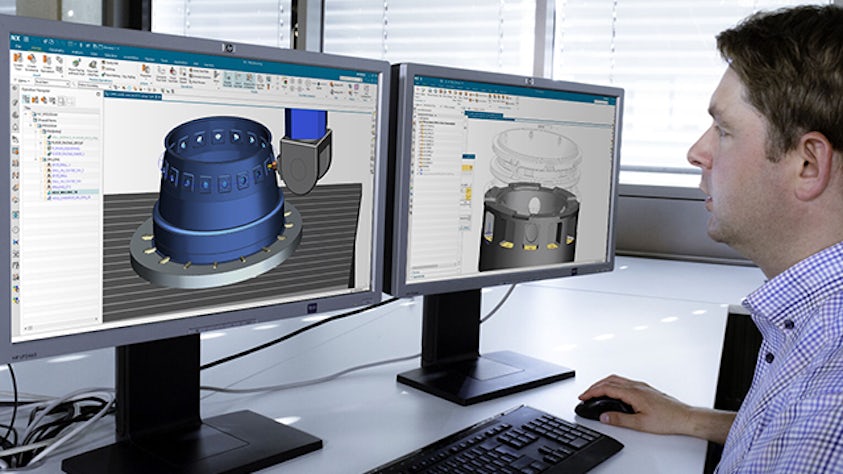

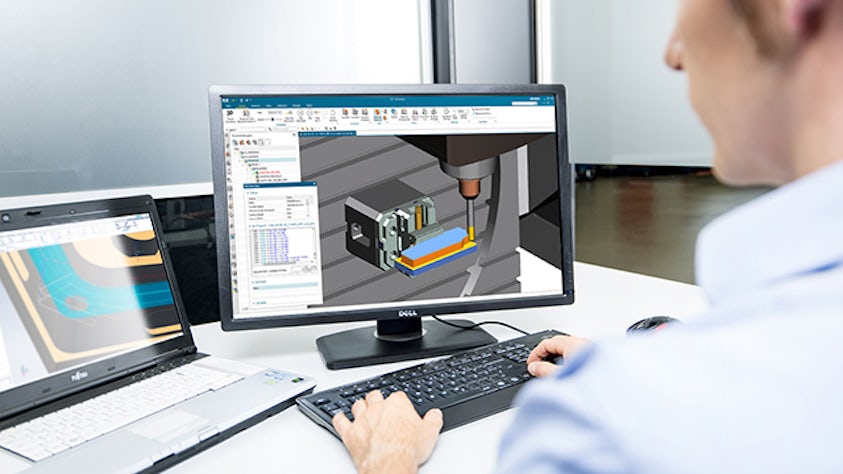

NX CAM software helps automate NC programming, accelerate machining, and manufacture high-precision parts using advanced toolpath technologies and integrated G-code-driven simulation.

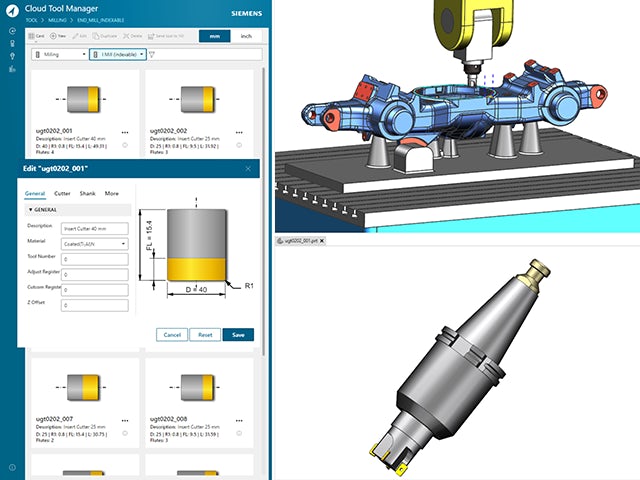

Empower your team with NX X Manufacturing, the next-generation software-as-a-service (SaaS) solution, which combines industry-leading computer-aided design and manufacturing (CAD/CAM) with the flexibility, security, and scalability of cloud technologies.

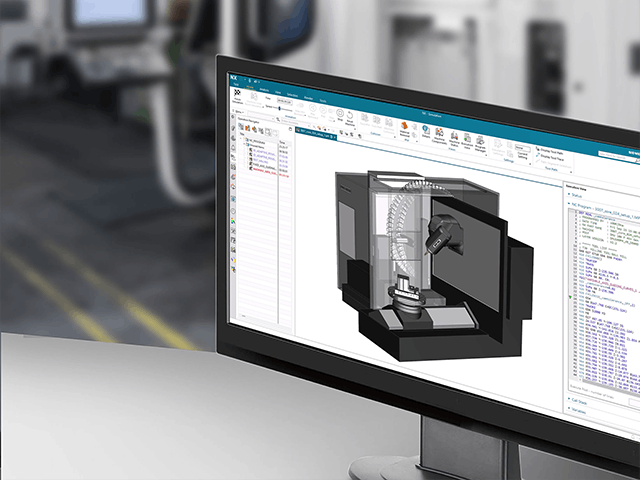

Stay ahead with the NX CAM seamless integration into our wider solution for digital manufacturing. Address the evolving industry needs with a range of software for 3D printing, robotics, production line design and more.