Seamlessly connect design and manufacturing teams using a comprehensive CAD/CAM software with advanced 3-axis milling capabilities, boosting your productivity.

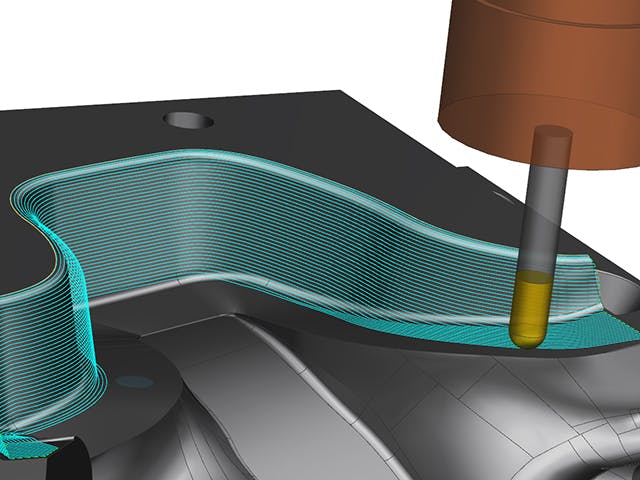

Accelerate machining and improve quality

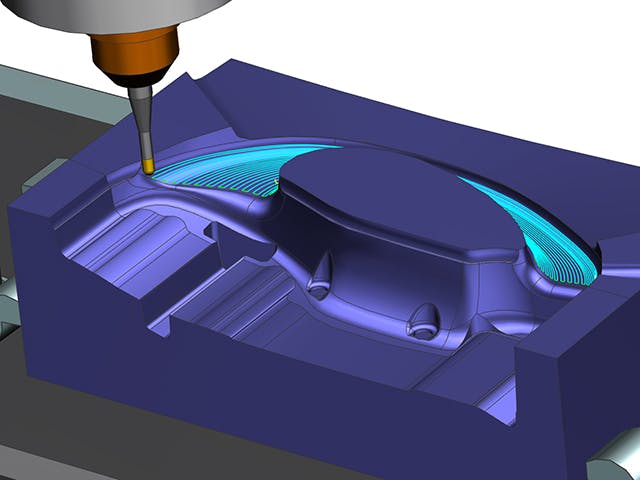

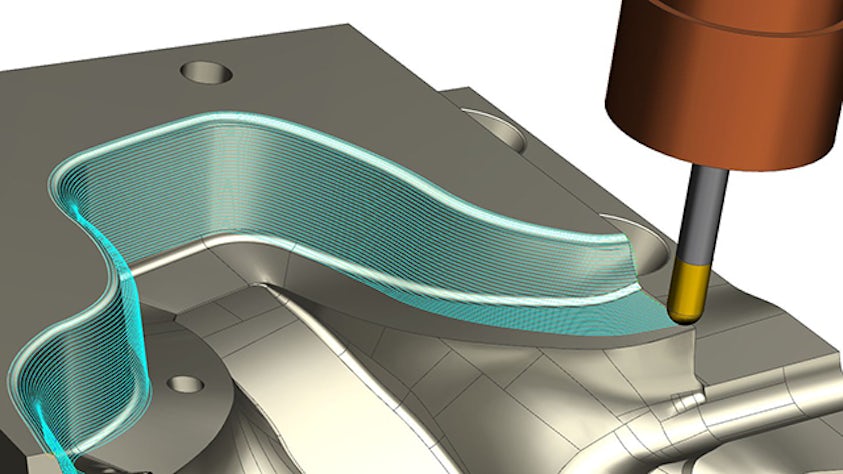

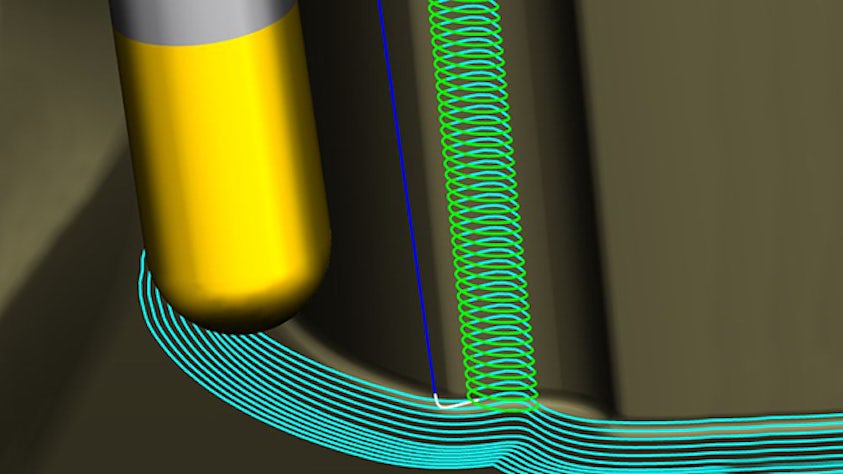

Machine higher quality freeform parts, such as molds and dies, using innovative toolpath technologies for roughing, rest milling and finishing. 3D Adaptive Roughing enables high material removal, reducing machining time by up to 60%.

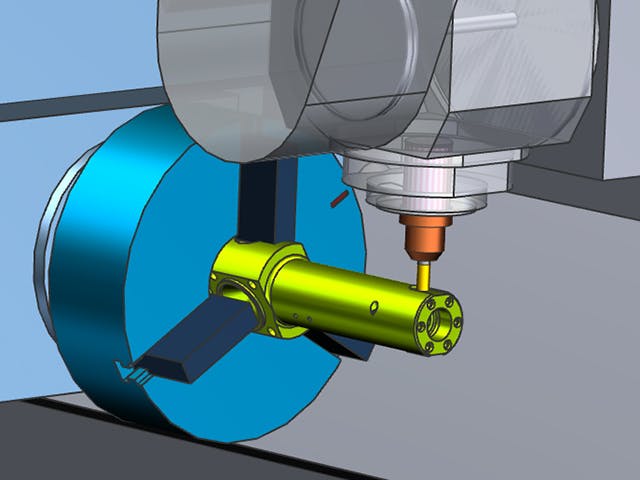

Design with integrated CAD

Design parts, blanks, fixtures and complete machine setups with industry-leading CAD tools for modeling and assembly. Quickly prepare part models for NC programming using synchronous technology.

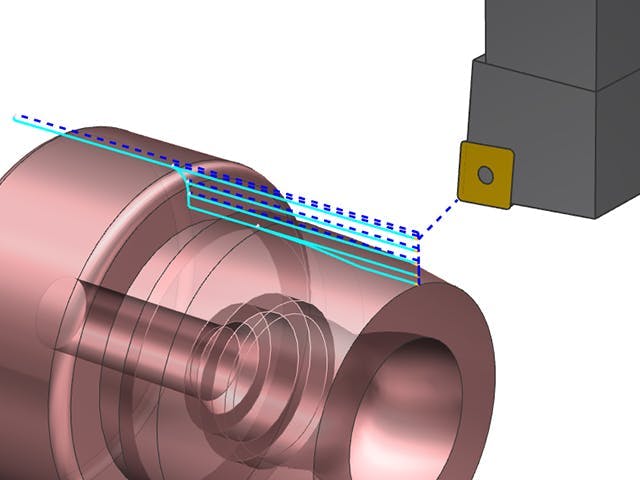

Output validated programs

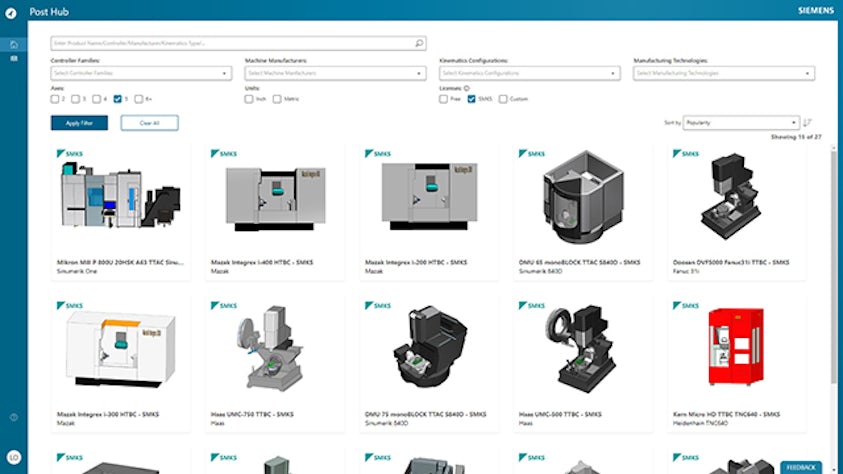

Generate validated, production-ready NC programs using the cloud-based postprocessing solution and integrated machining simulation. Digitally connect planning and production with associative shop documentation, including tool lists and setup sheets.

NX CAD/CAM provides advanced programming capabilities for 3-axis milling, including:

- 3D Adaptive Roughing

- Rest milling

- Guide curve finishing

- Z-level finishing

- Cut region control

- Spiral and helical finishing

- In-Process Workpiece (IPW)

- Toolpath verification

- Postprocessing

- Shop floor documentation

* The 2.5-axis milling capabilities are included too

Included integrated CAD tools:

- Synchronous technology

- Assemblies

- CAD translators

- Freeform modeling

- Design simulation

- Product and manufacturing information (PMI)

- Drafting