Métodos de prueba no destructivos, repetibles y estandarizados

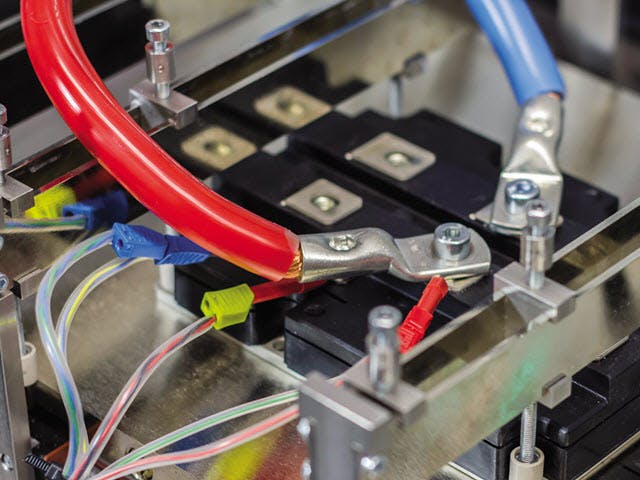

La familia de productos de hardware y software de Simcenter Micred está diseñada para evaluar el rendimiento térmico de los componentes electrónicos en condiciones estáticas y dinámicas. El sistema de análisis térmico transitorio funciona cambiando rápidamente la potencia calorífica aplicada de un dispositivo bajo prueba (DUT) y midiendo su respuesta a la temperatura. La temperatura de la unión se registra en función de un parámetro sensible a la temperatura elegido por el usuario durante la etapa de calibración. Los métodos cumplen con las directrices de la industria más adoptadas, como son las normas JEDEC y las directrices de cualificación automovilística (AQG) de ECPE. Los datos resultantes se utilizan para generar perfiles de impedancia térmica, que proporcionan información sobre el comportamiento térmico del componente.

Determinación de métricas térmicas, fiabilidad térmica y evaluación de calidad

A continuación, los perfiles de impedancia se utilizan para identificar posibles problemas térmicos, como el empeoramiento de la trayectoria térmica, y cualquier cambio en la resistencia térmica se puede rastrear hasta su ubicación. Es una excelente herramienta para diagnosticar los efectos térmicos en el envejecimiento, daños, fallos, etc., con detección en tiempo real de roturas de unión de cables, fatiga de soldadura o de troqueles y grietas en el material.

Alta fidelidad en un amplio espectro de aplicaciones

Las herramientas de prueba de Simcenter Micred ofrecen una gama de sistemas diseñados para satisfacer las necesidades de diferentes aplicaciones e industrias. Estos sistemas cuentan con tecnologías avanzadas de medición y control con alta exactitud, velocidad y precisión. Los utilizan los centros de investigación, así como las industrias de semiconductores, electrónica de consumo, automovilística y LED durante la ingeniería de componentes, la creación de prototipos y las pruebas.

Un legado de innovación

La familia de Simcenter Micred fue desarrollada inicialmente por investigadores del Departamento de Dispositivos Electrónicos de la Universidad de Tecnología y Economía de Budapest (BME). Siemens continúa llevando adelante este legado de innovación.

Caracterización térmica de paquetes de semiconductores: métricas térmicas, fiabilidad y calidad

Vea este webinar a la carta sobre caracterización térmica mediante tecnología de análisis térmico transitorio.