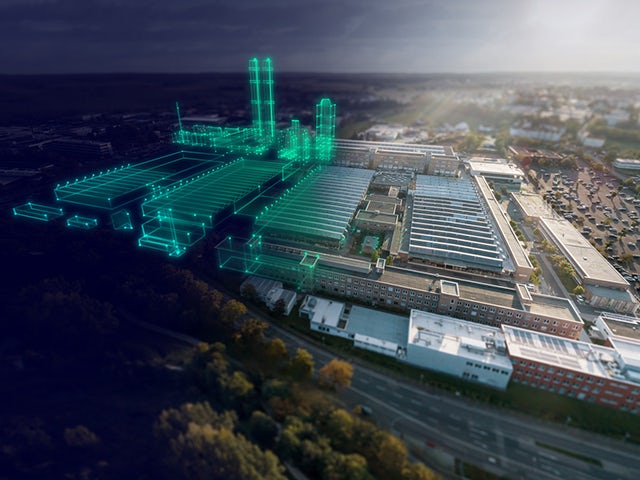

Designers are planning and virtually simulating the smart factories of the future through digitalized processes. The virtual factory is created in 3D with layout and optimization tools, allowing us to design, layout and configure the factory environment and optimize factory operations. By allowing facility planning and line design teams to see the outcome of plans virtually, you can avoid costly expenses and wasted resources that occur when problems are discovered in actual, physical facilities.

During factory line design and planning, the impact of equipment placement and access is difficult to realize using conventional factory layout tools. Understanding the throughput of individual lines of the factory is critical for manufacturers, as is understanding how material moves throughout the facility. Inefficiency can ripple throughout the factory and its production systems if you don't have the ability to optimize the factory layout based on the data obtained during the planning and analysis phases of production engineering.

With NX solutions, you can quickly design and visualize production line layouts and associate them with manufacturing planning. You can easily optimize the process by specifying each production step down to managing a single manufacturing resource, such as a robot or fixture.