How can you effectively design and realize innovative, sustainable and premium quality products for greater customer satisfaction?

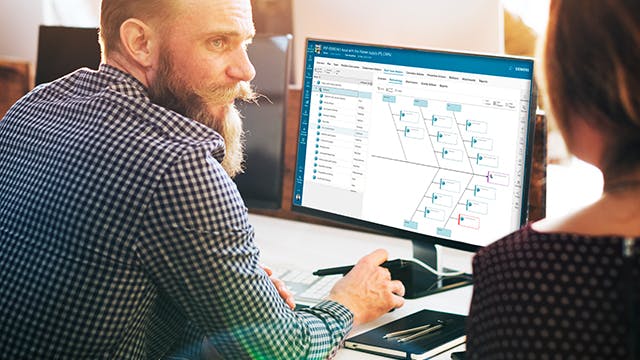

A digital closed-loop approach enables seamless quality management throughout the product lifecycle, supporting adherence to standards and industry guidelines, while maintaining reasonable costs for a faster return on investment.