Optimize your PCB assembly business

Reduce new product timeline

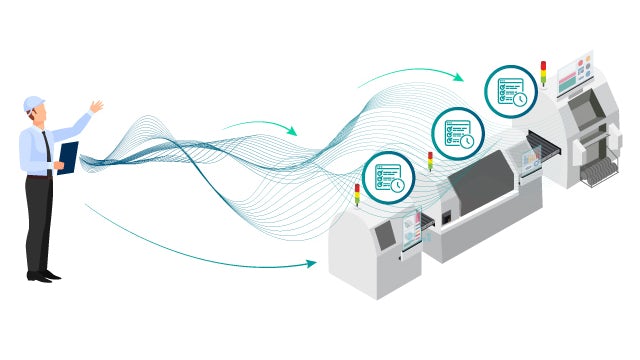

Simulate the product and process as designed—before actual production begins. Discover design flaws at earlier stages, making corrections quicker and less costly.

Make the most of SMT resources

Ensure your current resources are fully utilized and optimized for improved productivity before investing in expensive new machines and infrastructure.

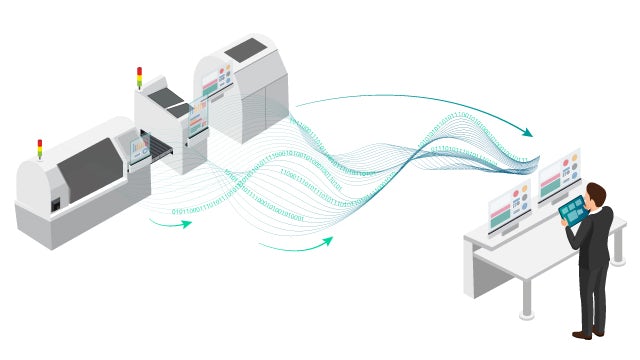

Gain real-time data visibility

Improve your control of operations and material use—knowing what's happening on the shop floor in real-time is crucial to preventing scrap and quality issues.

Egicon

Egicon uses Valor and Opcenter to reduce repair rates by 80 percent while eliminating scrap

Company:Egicon

Industry:Electronics, Semiconductor devices

Location:Mirandola, Modena, Italy

Siemens Software:Opcenter APS, Opcenter Execution Core, Opcenter Execution Electronics, Opcenter Execution Electronics IoT - MSS (Valor IoT manufacturing - Shopfloor), Opcenter Intelligence for On Premises, Valor Process Preparation

Maximize engineering and manufacturing productivity

Reduce design iterations, improve yield and optimize engineering and manufacturing productivity.

Optimize PCB assembly with Valor

As electronics manufacturing accelerates toward high-mix, low-volume production, it is necessary to turn to digitalization for success.