Méthodes d'essai non destructives, reproductibles et normalisées

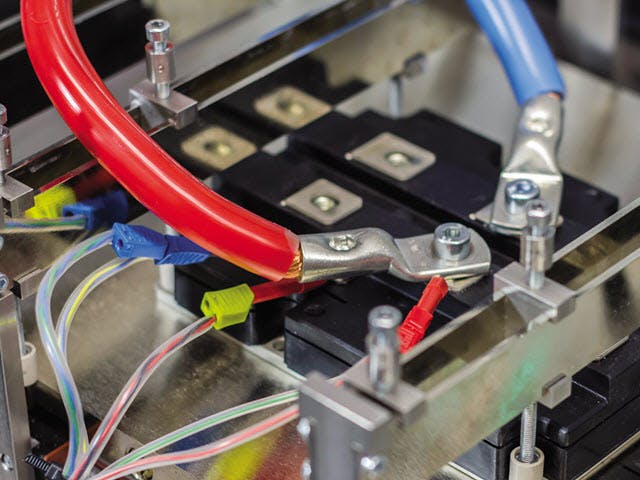

La famille de produits matériels et logiciels Simcenter Micred est conçue pour évaluer les performances thermiques des composants électroniques dans des conditions statiques et dynamiques. Le système d'essai thermique transitoire fonctionne en modifiant rapidement la puissance de chauffage appliquée à un dispositif testé (DUT) et en mesurant sa réponse en température. La température de jonction est enregistrée sur la base d'un paramètre sensible à la température choisi par l'utilisateur lors de la phase d'étalonnage. Les méthodes sont conformes aux lignes directrices largement adoptées par l'industrie, telles que les normes JEDEC et les lignes directrices de l'ECPE pour la qualification automobile (AQG). Les données obtenues sont utilisées pour générer des profils d'impédance thermique, qui donnent un aperçu du comportement thermique du composant.

Détermination des mesures thermiques, fiabilité thermique et évaluation de la qualité

Les profils d'impédance sont ensuite utilisés pour identifier les problèmes thermiques potentiels, tels que la dégradation des trajectoires thermiques, et tout changement de résistance thermique peut être suivi jusqu'à un emplacement. Il s'agit d'un excellent outil pour diagnostiquer les effets thermiques du vieillissement, des dommages, des défaillances, etc., avec une détection en temps réel des ruptures de liaison des fils, de la fatigue de la soudure, des fissures de la matrice et du substrat.

Haute fidélité dans un large éventail d'applications

Les outils de test Simcenter Micred offrent une gamme de systèmes conçus pour répondre aux besoins des différentes applications et industries. Ces systèmes sont dotés de technologies de mesure et de contrôle avancées, d'une grande précision et d'une grande rapidité. Ils sont utilisés par les centres de recherche ainsi que par les industries des semi-conducteurs, de l'électronique grand public, de l'automobile et des diodes électroluminescentes lors de l'ingénierie des composants, du prototypage et des essais.

Un héritage d'innovation

La famille Simcenter Micred a été initialement développée par des chercheurs du département des dispositifs électroniques de l'Université de technologie et d'économie de Budapest (BME). Siemens continue de perpétuer cet héritage d'innovation.

Caractérisation thermique des boîtiers semi-conducteurs – mesures thermiques, de la fiabilité à la qualité

Regardez ce webinaire à la demande sur la caractérisation thermique à l'aide de la technologie de mesure des transitoires thermiques.