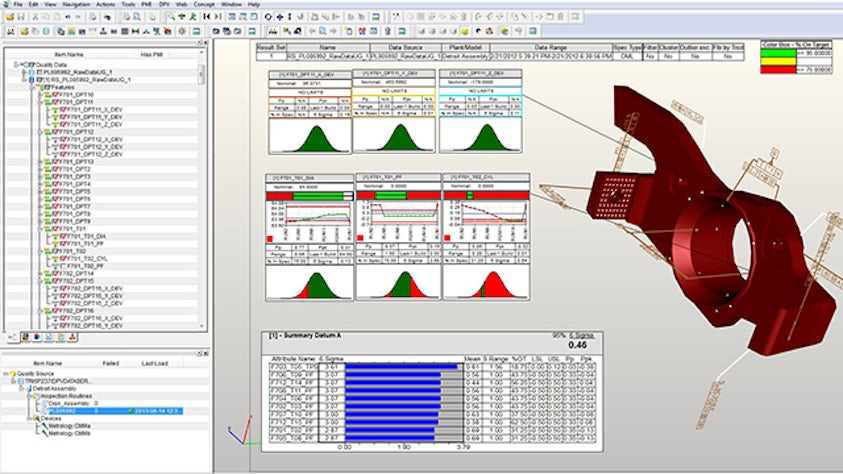

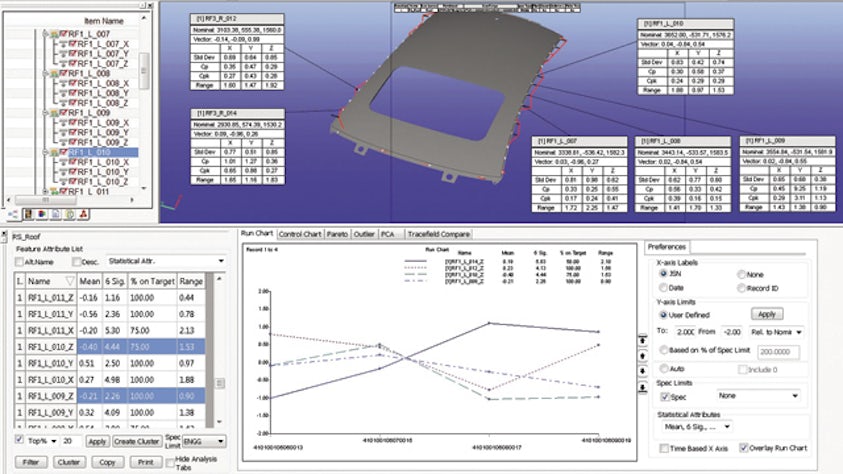

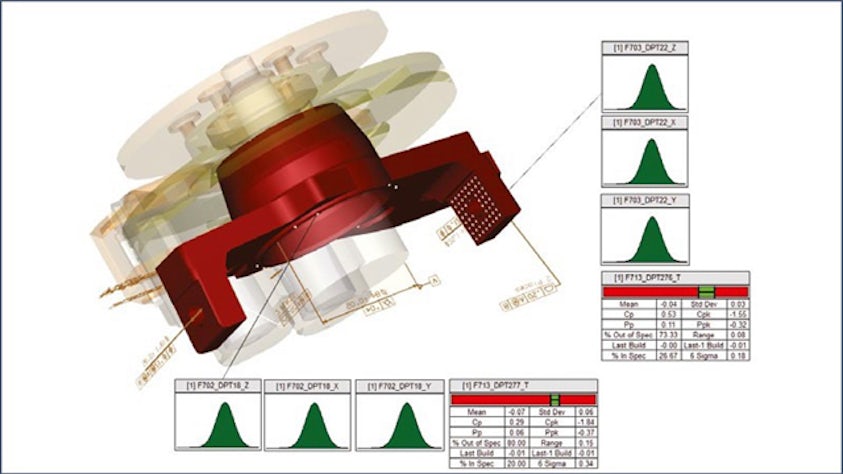

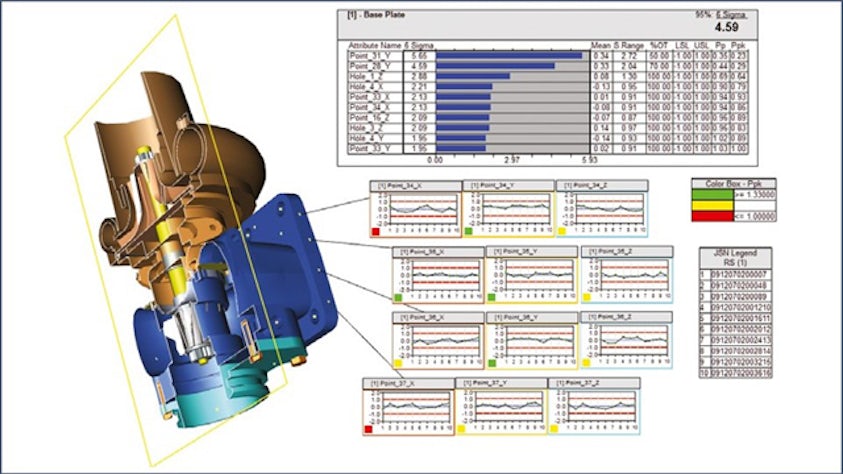

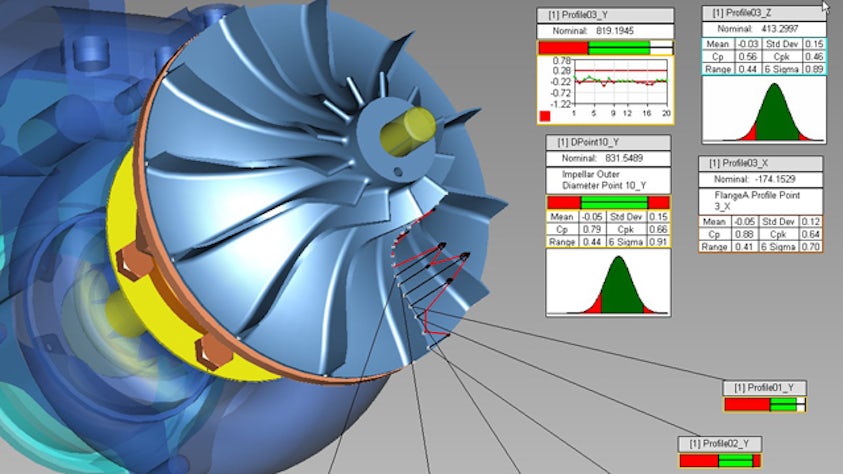

Intégrez des paramètres de qualité dimensionnelle dans la conception des produits et le processus de planification de la fabrication afin d'éviter des problèmes de qualité coûteux :

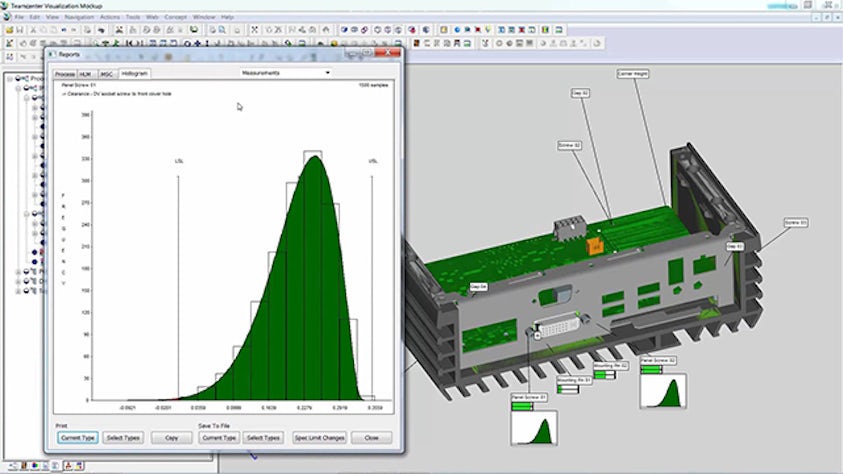

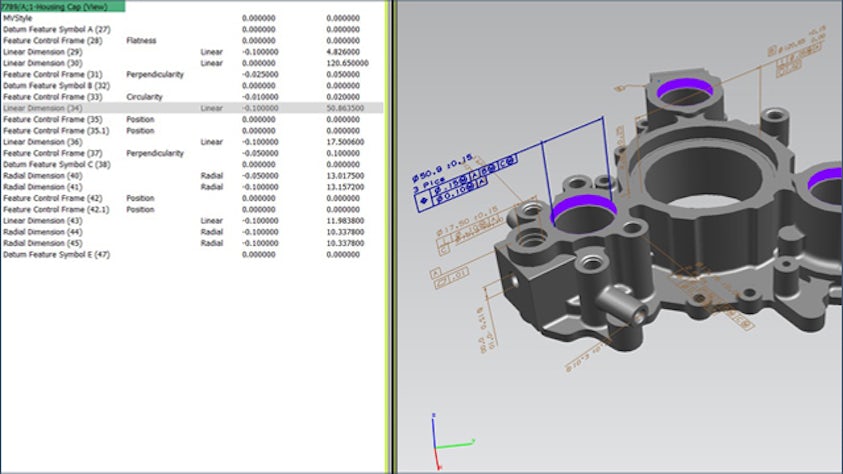

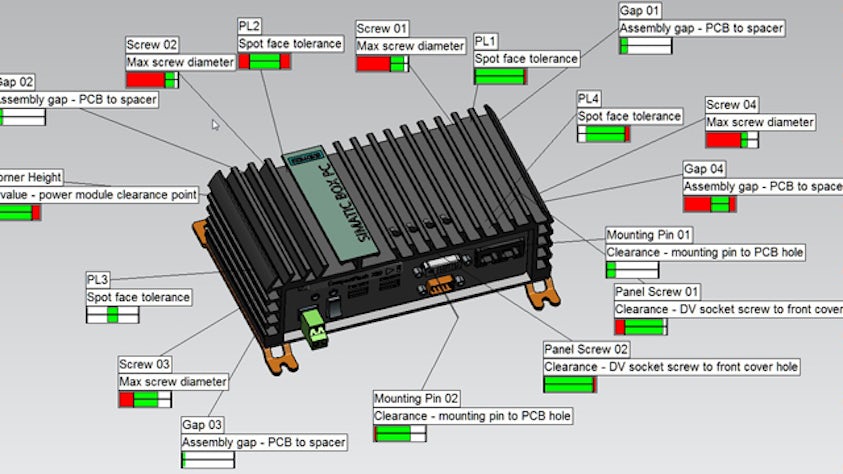

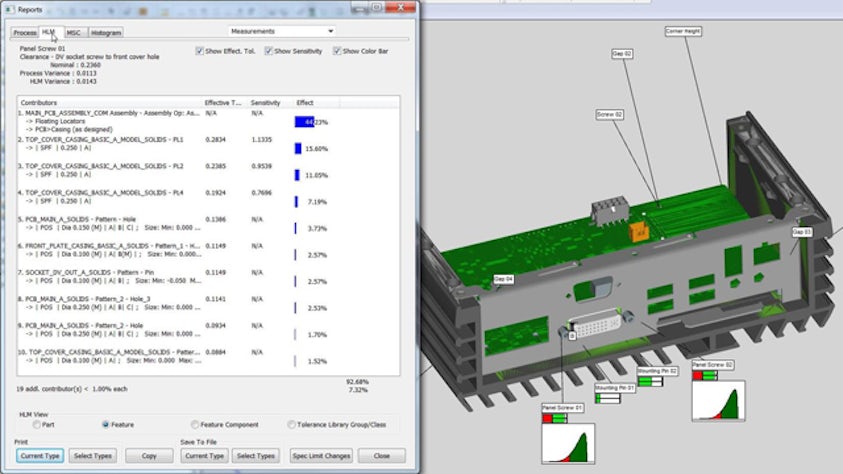

- Garantissez la qualité du produit lors de la production en comprenant l'incidence de la variation dimensionnelle avant la revue de conception

- Analysez l'impact des processus de fabrication sur les caractéristiques et les tolérances de conception, en mettant en évidence les sources et les quantités de variation dimensionnelle afin d'améliorer la qualité de la fabrication et d'éliminer les coûts