連携を始め、そのまま連携を維持しましょう。

シミュレーションと物理的なテストに必要なすべてのツール、データ、プロセスを管理します。また、組織内の適切な意思決定者に結果をすばやく提供します。

シミュレーション・データ管理とデジタル・トランスフォーメーション

シミュレーション・プロセスおよびデータ管理 (SPDM) システムは多くのメリットをもたらします。デジタル・トランスフォーメーション時代を迎えた今、シミュレーション・データを共有ファイル・システムで部門ごとに個別管理している場合ではありません。生産性向上の基盤としてSPDMシステムを検討すべきです。

シミュレーションとテストのデジタル・スレッドを実現

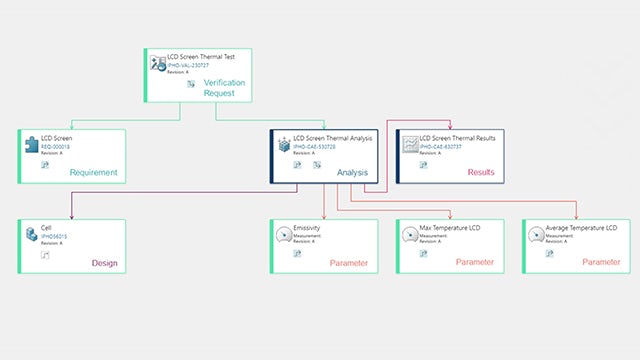

シミュレーションや、テストプロセス、データ管理といったすべてのパフォーマンス領域にわたり、完全なトレーサビリティを実現します。製品開発のすべての段階で使用されるモデルとエンジニアリング・データの関係を自動構築することで、シミュレーションとテストをつなげたデータをデジタル・スレッドで活用することができます。デジタルツイン、モデルベース・システム・エンジニアリング (MBSE)、検証管理などの主要な手法をサポートしています。

ワークフローによってエンジニアリングの生産性を向上

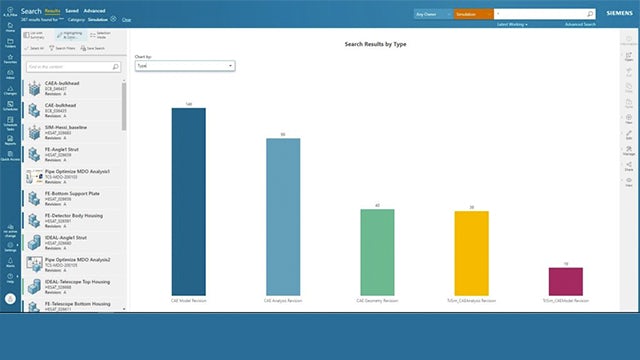

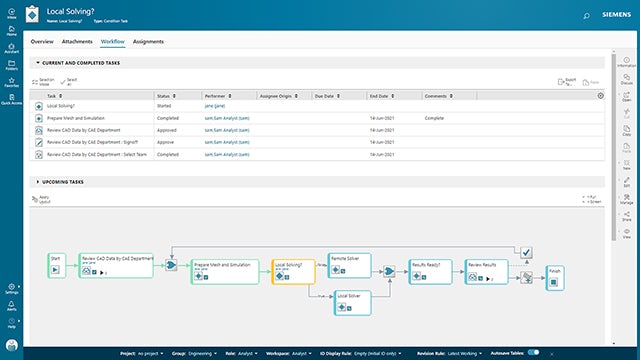

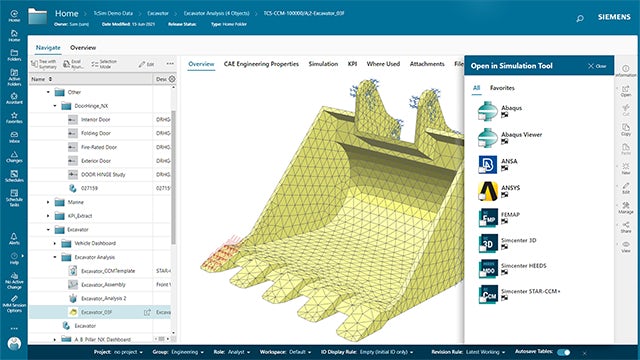

強力な検索機能を使って参照データやモデルをすばやく見つけ、新しいモデルと解析を効率的に設定し、シミュレーションとMDAO (複数領域にまたがる解析と最適化) スタディを調整します。テンプレート化および自動化されたワークフローによって、シミュレーションが可能になるだけでなく、モデル構築プロセスで発生する手動およびミスの起きやすいタスクが不要になります。データとモデルを再利用して時間を節約し、結果品質を保証します。

エンジニアリングの知識を取り込み、迅速な意思決定を促進

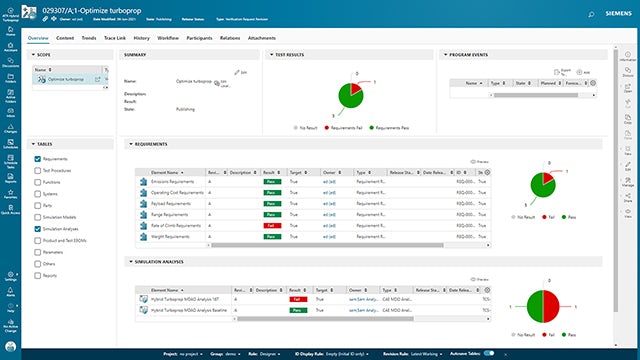

単一のシステムで1D、3D、テストのデータとプロセスを管理し、複雑なエンジニアリング要件に対応します。自動抽出されるKPIを通じて、結果や知見をすべての関係者と簡単に共有できます。軽量ビジュアリゼーションとカスタマイズ可能なダッシュボードにより、意思決定者はシミュレーションとテストの専任者が行った作業を活用することができます。

シミュレーションおよびテストツールのオープン・ソリューションを活用

インストール不要のクライアントと安全なマルチサイト・アクセスによって障壁を取り払い、シームレスなコラボレーションとアクセスを実現します。オープン・プラットフォームであるTeamcenter Simulationは素早く導入できて、市販または内製のシミュレーション・ソフトウェアとも容易に統合して、お使いのエンジニアリング・ワークフローに組み込むことができます。Simcenterポートフォリオだけでなく、任意のサードパーティ製CADやシミュレーション・ツールとも統合できます。

NEVS

高い精度のデジタルツインで持続可能なモビリティ・ソリューションを開発

会社:NEVS

業界:自動車 / 輸送機器

開催場所:トロルヘッタン, Sweden

シーメンスデジタルインダストリーズソフトウェア:HEEDS, Polarion, Simcenter 3D Solutions, Teamcenter