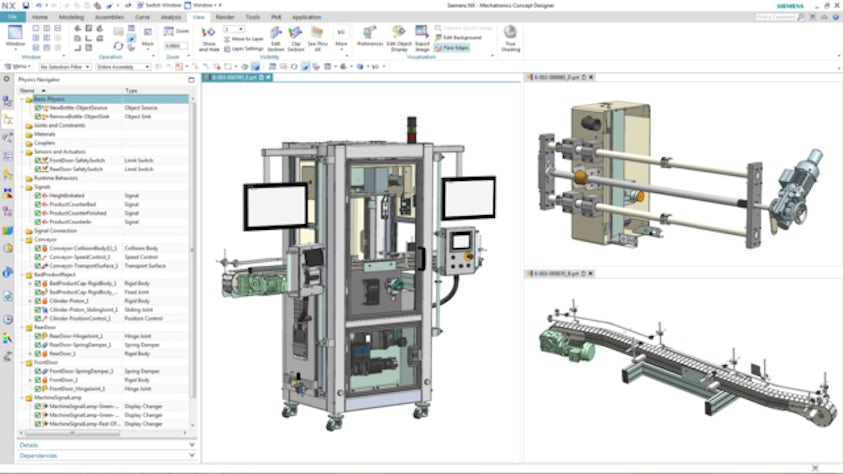

Na podstawie danych wyjściowych aplikacji Mechatronics Concept Designer można kontynuować doskonalenie projektów bez konieczności ponownego analizowania danych, bezpośrednio i w wielu domenach.

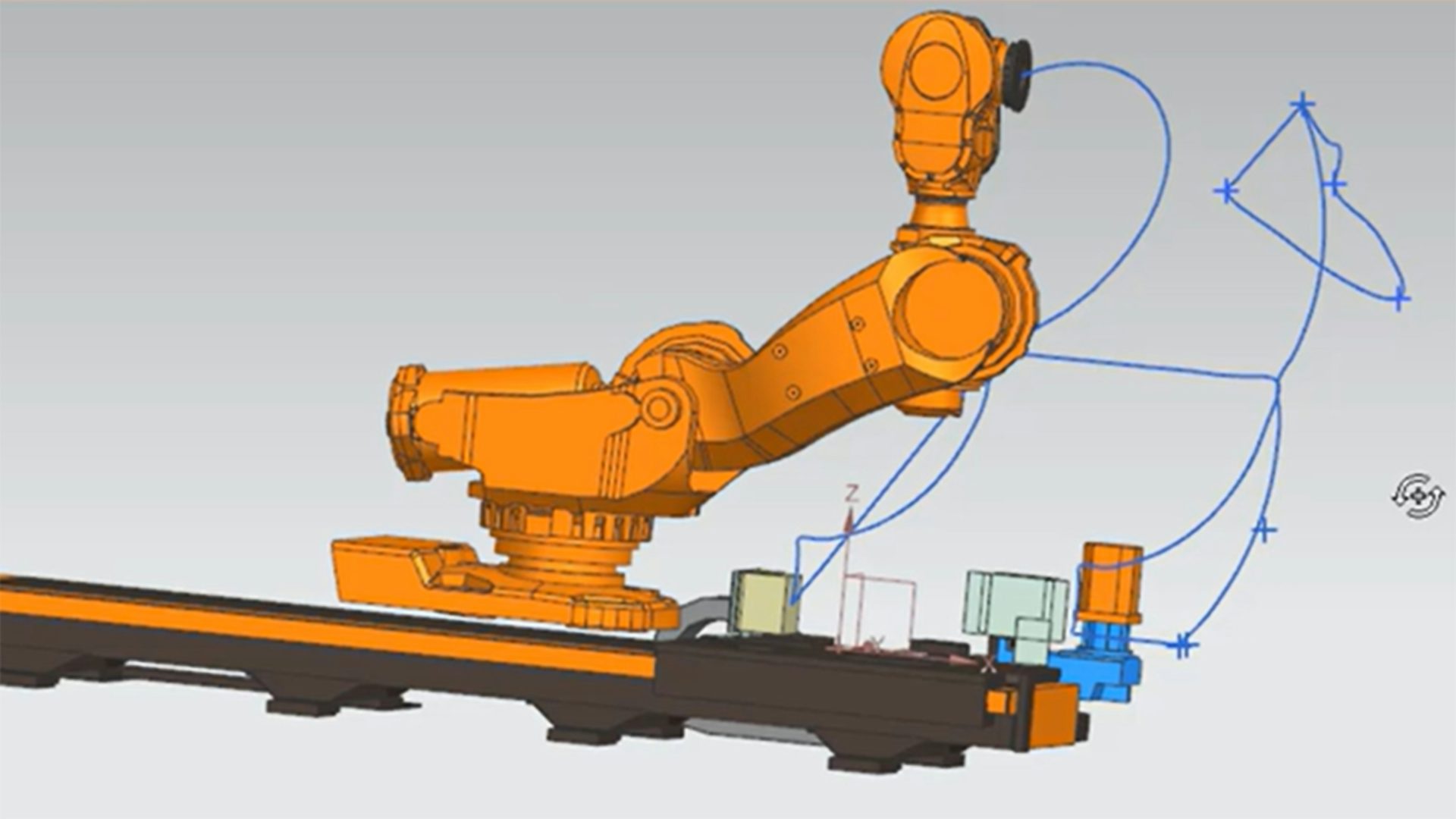

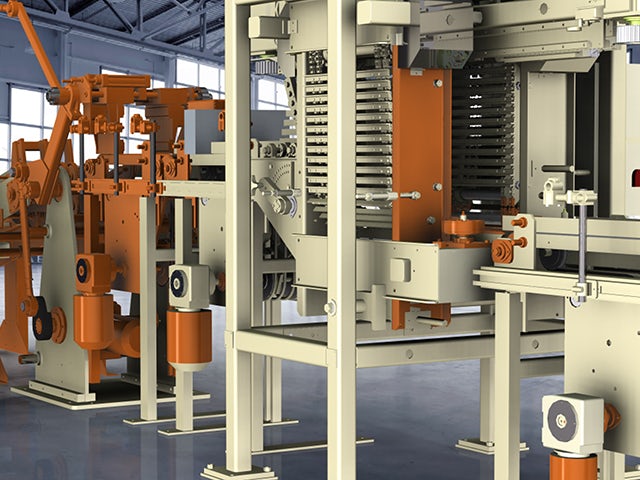

- Projektanci urządzeń mechanicznych mogą korzystać z modeli koncepcyjnych w oprogramowaniu NX do tworzenia szczegółowych projektów.

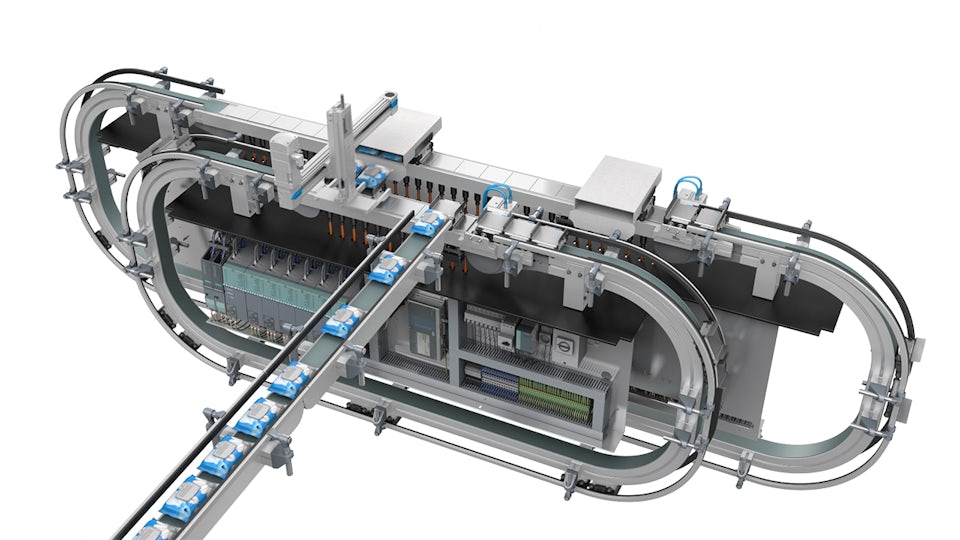

- Projektanci instalacji elektrycznych mogą opierać się na danych modelu,wybierając czujniki i urządzenia uruchamiające.

- Projektanci układów automatyki mogą używać kamer i informacji o kolejności działań uzyskanych z modelu do opracowywania oprogramowania.